A kind of anti-arc fabric and preparation method thereof

A technology of anti-arc and fabrics, which is applied in the direction of woven fabrics, textiles, textiles and papermaking, etc., can solve the problem of smoldering of anti-arc fabrics, and achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing an arc-proof fabric of the present invention is specifically implemented according to the following steps:

[0031] Step 1, weighing according to mass percentage: 50% to 80% of meta-aramid fiber, 15% to 40% of high modulus high temperature resistant and structurally stable fiber, 3% to 8% of nylon fiber and 2% of conductive fiber, the above The sum of the mass percentages of the components is 100%;

[0032] The high modulus high temperature resistant structural stability fiber is para-aramid fiber or PBO fiber;

[0033] Step 2, pretreatment: fully mix meta-aramid fibers, high-modulus high-temperature-resistant structurally stable fibers and antistatic agents, and let them stand for 24 hours to make the fibers fully absorb moisture and penetrate, which can effectively improve the spinnability and yield of the fibers. yarn quality;

[0034] The quality of adding antistatic agent is 3‰~5‰ of the sum of the quality of meta-aramid fiber and high-modu...

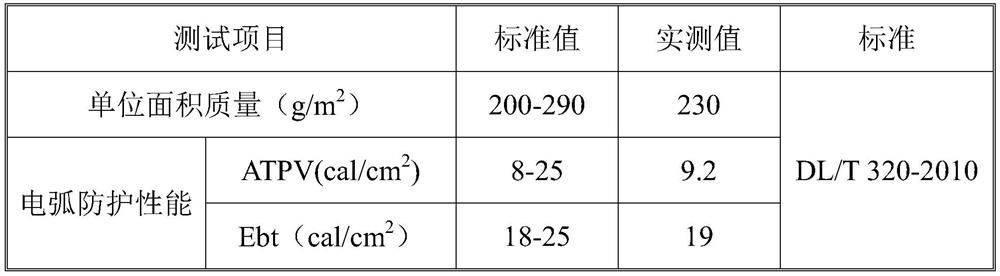

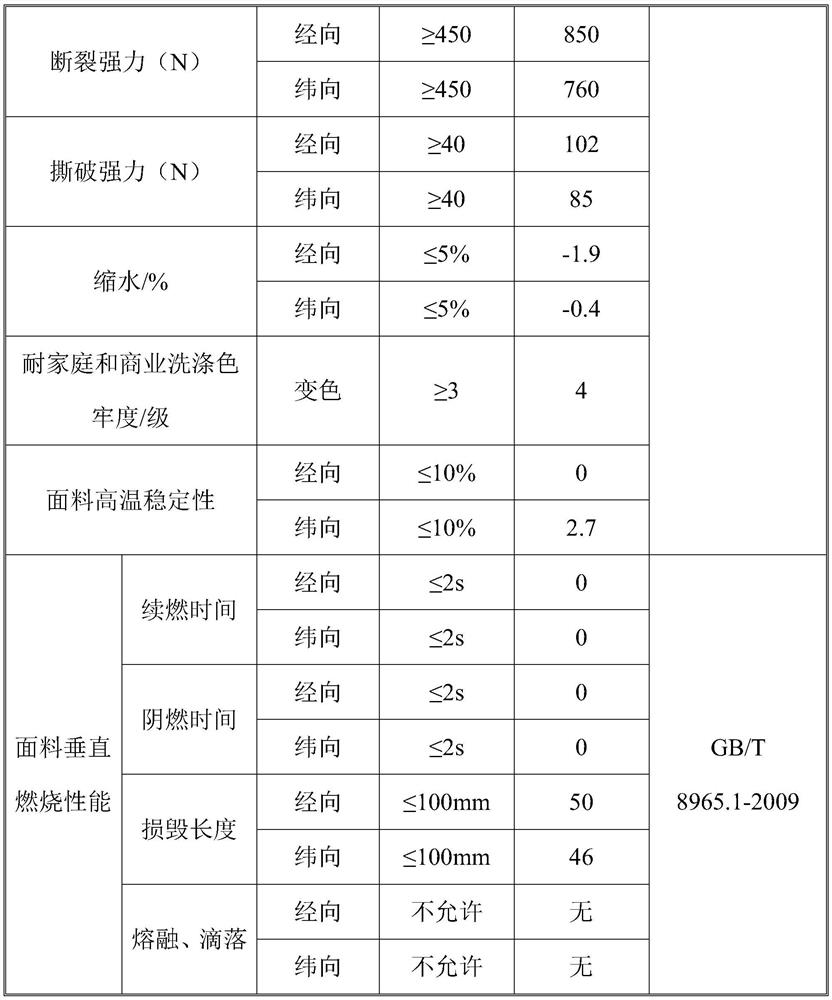

Embodiment 1

[0044] The invention provides an anti-arc fabric, which is formed by interweaving warp yarns and weft yarns. The warp yarns and weft yarns both include the following components in mass percentage: 50% meta-aramid fibers, 40% para-aramid fibers, and 8% nylon fibers. % and conductive fiber 2%, the sum of the mass percentages of the above components is 100%;

[0045] The linear density of both warp and weft is 14.8tex×2;

[0046] The fabric structure is 2 / 1 twill weave;

[0047] The mass per unit area of the fabric is 200g / m 2 ;

[0048] A method for preparing an arc-proof fabric of the present invention is specifically implemented according to the following steps:

[0049]Step 1, weighing by mass percentage: 50% of meta-aramid fiber, 40% of para-aramid fiber, 8% of nylon fiber and 2% of conductive fiber, the sum of the mass percentages of the above components is 100%;

[0050] Step 2, pretreatment: fully mix the meta-aramid fiber, para-aramid fiber and antistatic agent, an...

Embodiment 2

[0058] The invention provides an anti-arc fabric, which is formed by interweaving warp yarns and weft yarns. The warp yarns and weft yarns both include the following components in mass percentage: 60% of meta-aramid fibers, 33% of PBO fibers, 5% of nylon fibers and conductive Fiber 2%, the sum of the mass percentages of the above components is 100%;

[0059] The linear density of both warp and weft is 18.5tex×2;

[0060] The fabric structure is 3 / 1 twill weave;

[0061] The mass per unit area of the fabric is 220g / m 2 ;

[0062] A method for preparing an arc-proof fabric of the present invention is specifically implemented according to the following steps:

[0063] Step 1, weighing by mass percentage: 60% of meta-aramid fiber, 33% of PBO fiber, 5% of nylon fiber and 2% of conductive fiber, the sum of the mass percentage of the above components is 100%;

[0064] Step 2, pretreatment: fully mix the meta-aramid fiber, PBO fiber and antistatic agent, and let it stand for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com