Stone-plastic lightweight vcp floor and preparation method thereof

A lightweight, floor-to-ceiling technology, applied to chemical instruments and methods, synthetic resin layered products, floors, etc., can solve the problems of time consumption, manpower and resources, lower yield of production links, and unsatisfactory thickness control. , to achieve good gloss and scratch resistance, reduce transportation costs, and reduce shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0033] The preparation method of stone-plastic lightweight VCP flooring includes PVC layer processing, VCP substrate processing, lamination, cold pressing, surface UV treatment and slotting processes, as follows:

[0034] 1. Processing of PVC layer: mainly thermal compound processing, the prepared wear-resistant layer and printed color film are stacked on the carrying plate of the flat vulcanizer, the temperature is set at 120-150°C, and after thermal compounding for 10-20 minutes Release the mold, complete the thermal lamination of the wear-resistant layer and the printed color film, and wait for lamination. Among them, the thickness of the wear-resistant layer is 0.5mm, and the thickness of the color film is 0.07mm.

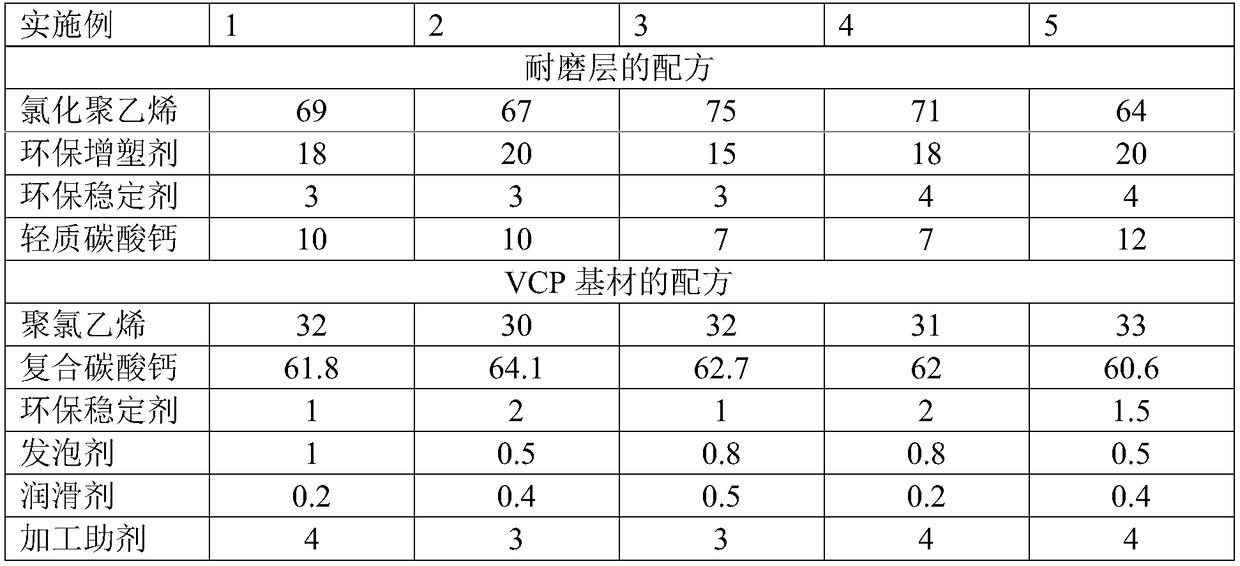

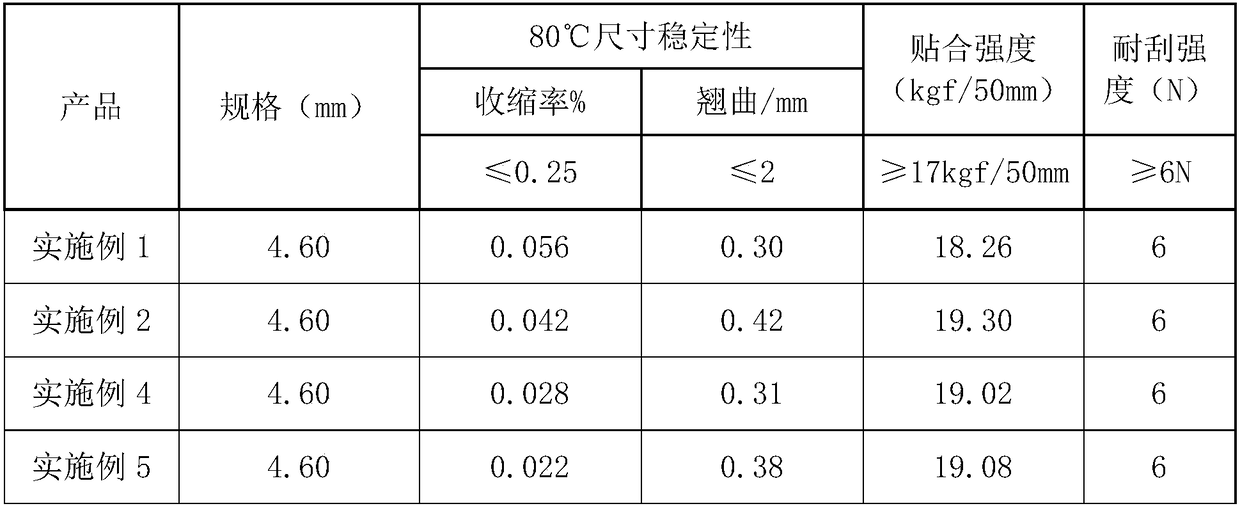

[0035] Preparation of the wear-resistant layer: the formula of the wear-resistant layer is shown in Table 1. Put the raw materials into a high-speed mixer and mix them at a speed of 1500 rpm. After 5-6 minutes, the materials are fed to the planetary machine, an...

Embodiment 4

[0045] The preparation method of stone-plastic lightweight VCP flooring includes PVC layer processing, VCP substrate processing, lamination, cold pressing, surface UV treatment and slotting processes, as follows:

[0046] 1. Processing of PVC layer: mainly thermal compound processing. The prepared wear-resistant layer and printed color film are stacked on the carrying plate of the flat vulcanizer. The thermal lamination of the wear-resistant layer and the printed color film is to be used after lamination. Among them, the thickness of the wear-resistant layer is 0.3mm, and the thickness of the color film is 0.07mm.

[0047] Preparation of the wear-resistant layer: the formula of the wear-resistant layer is shown in Table 1. Put the raw materials into a high-speed mixer and mix them at a speed of 1500 rpm. After 5-6 minutes, the materials are fed to the planetary machine, and the materials are mixed and discharged by the planetary machine until the kneading is started. Roller, th...

Embodiment 5

[0054] The preparation method of stone-plastic lightweight VCP flooring includes PVC layer processing, VCP substrate processing, lamination, cold pressing, surface UV treatment and slotting processes, as follows:

[0055] 1. Processing of PVC layer: mainly thermal compound processing. The prepared wear-resistant layer and printed color film are stacked on the carrying plate of the flat vulcanizer. The temperature is set at 150°C, and the mold is demoulded after thermal compounding for 16 minutes, and the process is completed. The thermal lamination of the wear-resistant layer and the printed color film is to be used after lamination. Among them, the thickness of the wear-resistant layer is 0.35mm, and the thickness of the color film is 0.07mm.

[0056] Preparation of the wear-resistant layer: the formula of the wear-resistant layer is shown in Table 1. Put the raw materials into a high-speed mixer and mix them at a speed of 1500 rpm. After 5-6 minutes, the materials are fed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com