A large-size light-weight decorative gypsum ceiling and its preparation method

A ceiling and large-size technology, which is applied in the field of large-size light-weight decorative gypsum ceiling and its preparation, can solve the problems of large sag deflection and cannot meet the requirements of use, and achieve the effect of reducing unit area, mass and sag deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

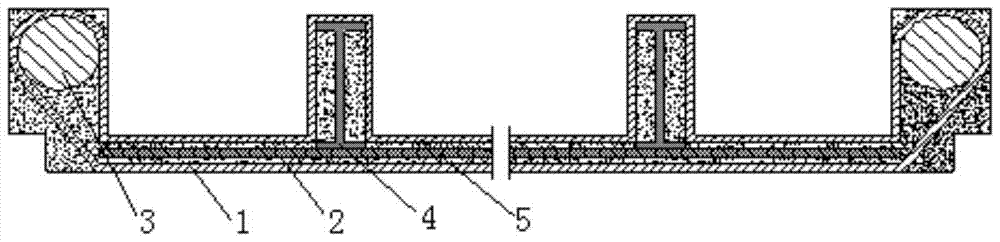

[0024] refer to figure 1 , the large-size light-weight decorative gypsum ceiling (1200*1200*18mm) of this embodiment includes a gypsum ceiling body, and the first layer of glass fiber felt 1, glass fiber grid cloth 2, glass fiber Rod 3, aluminum alloy keel 4 and second layer of glass fiber mat 5, the first layer of glass fiber mat 1 is located at the bottom of the gypsum ceiling body, and the glass fiber mesh cloth 2 is located above the first layer of glass fiber mat 1 , the glass fiber rods 3 are four, evenly distributed around the gypsum ceiling body, and wrapped by the first layer of glass fiber felt 1, the aluminum alloy keel 4 is located above the glass fiber grid cloth 2, the first The two-layer glass fiber mat 5 is located on the top of the gypsum ceiling body, and wraps the aluminum alloy keel 4 and the glass fiber rod 3 .

[0025] In this embodiment, there are two aluminum alloy keels 4, which are evenly distributed in the main body of the gypsum ceiling.

[0026] ...

Embodiment 2

[0037] The large-size lightweight decorative gypsum ceiling of this embodiment is 1200*2400*18mm, and its structure differs from that of Embodiment 1 in that the number of aluminum alloy keels is five.

[0038] Its preparation method comprises the following steps:

[0039] (1) Take by weighing 18 kilograms of gypsum powder, pour it into a stirring bucket filled with 12.6 kilograms of water while shaking, stir after soaking the powder for 30 seconds, and obtain a gypsum slurry;

[0040] (2) Take gypsum slurry (4 liters), pour it into the PVC mold, smooth it, and do not expose the bottom;

[0041] (3) Lay the first layer of glass fiber felt (1.3*2.5 meters), and level it out so that the slurry overflows evenly;

[0042] (4) Pour the slurry (4 liters) into the PVC mold again, smooth it, lay the glass fiber mesh cloth (1.2*2.4 meters), and smooth it again, so that the slurry evenly soaks the glass fiber mesh cloth;

[0043] (5) Pour the slurry (4 liters) into the PVC mold again,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com