Heat preservation and insulation plate frame integrated internal wallboard structure and production method

A technology of thermal insulation board and thermal insulation layer, which is applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of low strength of thermal insulation materials, affecting the strength of walls or load-bearing capacity, and achieve enhanced load-bearing and structural seismic performance Good, improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment is an exemplary heat-insulation panel frame-integrated interior wall panel structure.

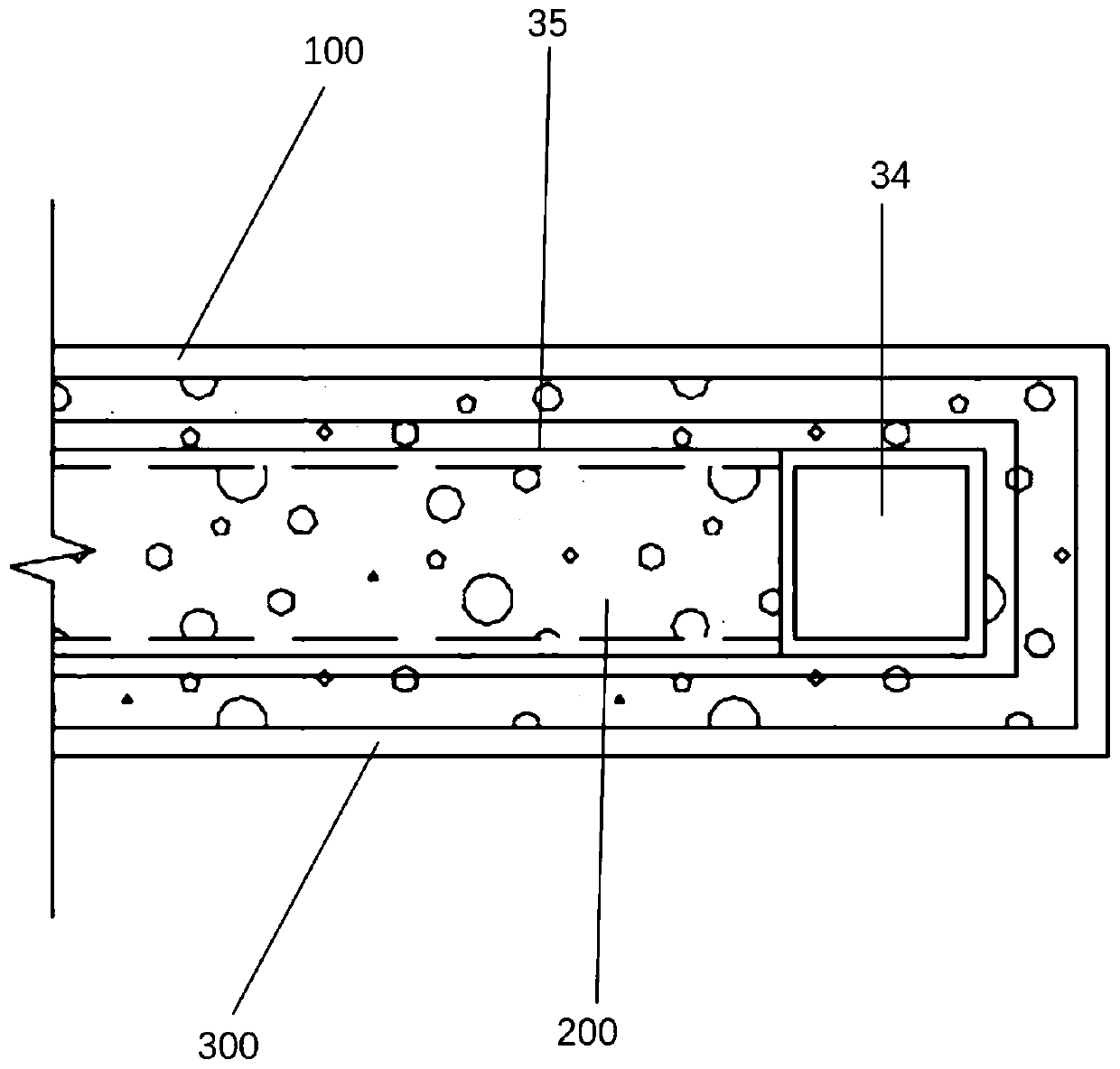

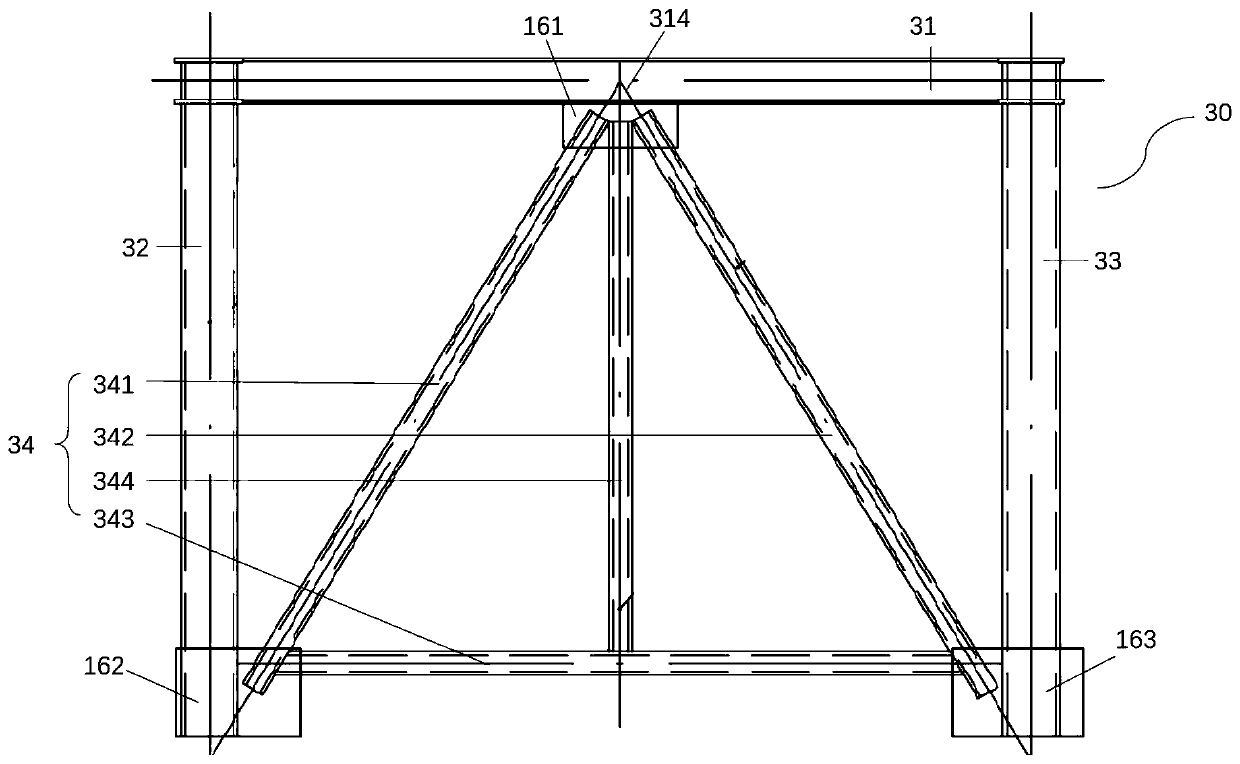

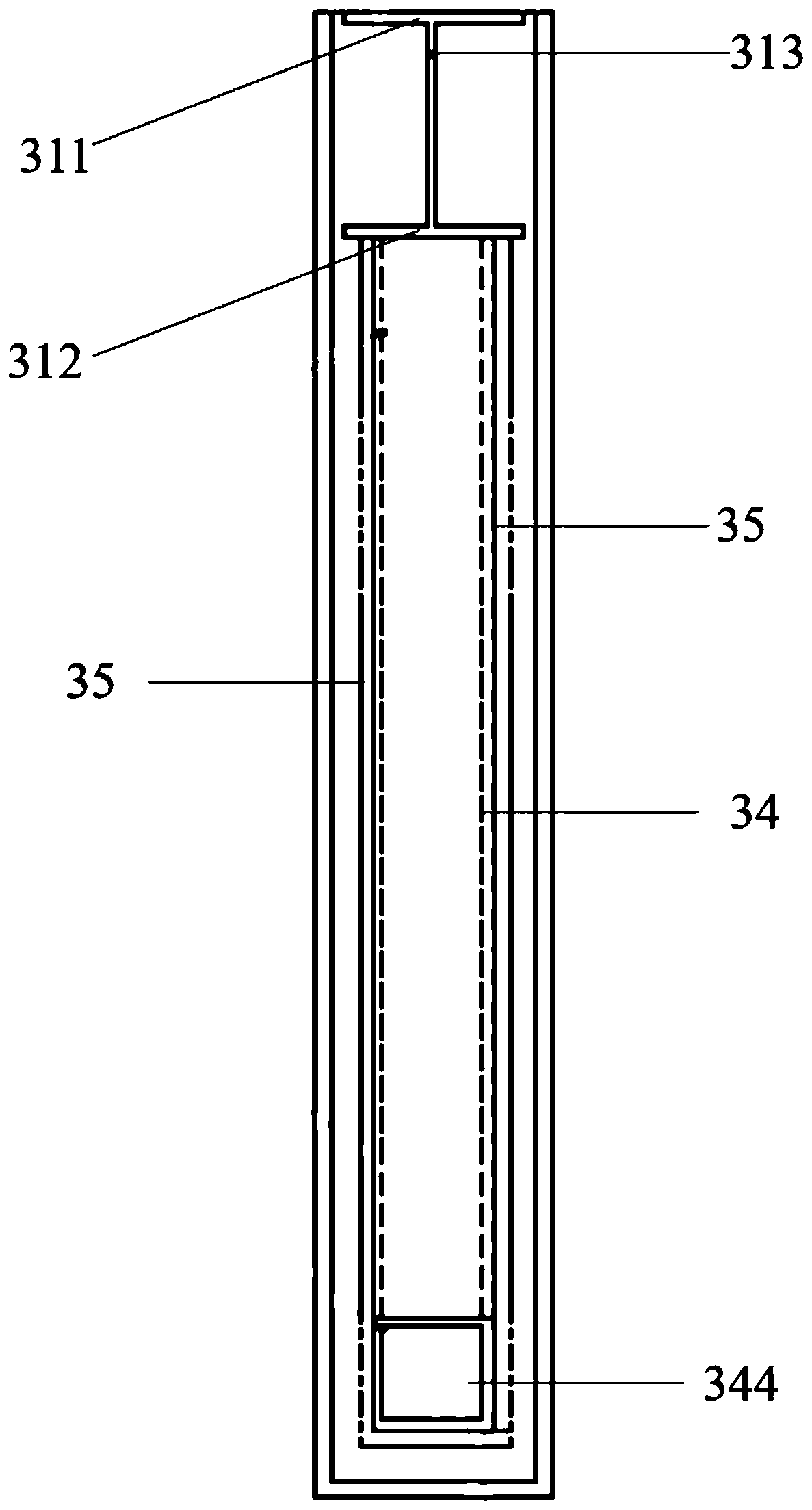

[0068] figure 1 It is a schematic cross-sectional view of the thermal insulation board frame combined with an inner wall board in this embodiment. Such as figure 1 As shown, the structure of the thermal insulation panel frame combined with an inner wall panel in this embodiment includes the first protective layer 100 , the thermal insulation layer 300 and the second protective layer 200 sequentially from outside to inside in the thickness direction. In this embodiment, the heat-insulation and heat-insulation panel frame-integrated interior wall panel structure also has a load-bearing skeleton, figure 1 Part of the structure shown as a load-bearing skeleton, such as supports 34 and wire mesh 35, is shown in FIG.

[0069] The first protective layer 100 and the second protective layer 200 are respectively disposed on two sides of the thermal insulation layer 300 . Th...

Embodiment 2

[0076] In addition to changing the raw material of the thermal insulation layer 300 to the following, and the bulk density of the thermal insulation layer obtained is 530kg / m 3 Except, the others are the same as in Example 1.

[0077] 100kg of vitrified beads, 250kg of cement, 220kg of sand, 540kg of fly ash ceramsite, 50kg of fly ash, 45kg of additives and 250kg of water. Wherein, the additive is obtained by mixing materials in the following weight ratio: 25:50:50:30:5 dialkyl dimethyl amine oxide, lime, gypsum, polyurethane and sodium hexametaphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com