Bolt connection-based rapid assembling precast rectangular concrete filled steel tube bridge pier

A rectangular steel pipe and concrete technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of less research and development and application of steel pipe concrete, achieve good compression resistance, save prefabrication costs, and reduce traffic delays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

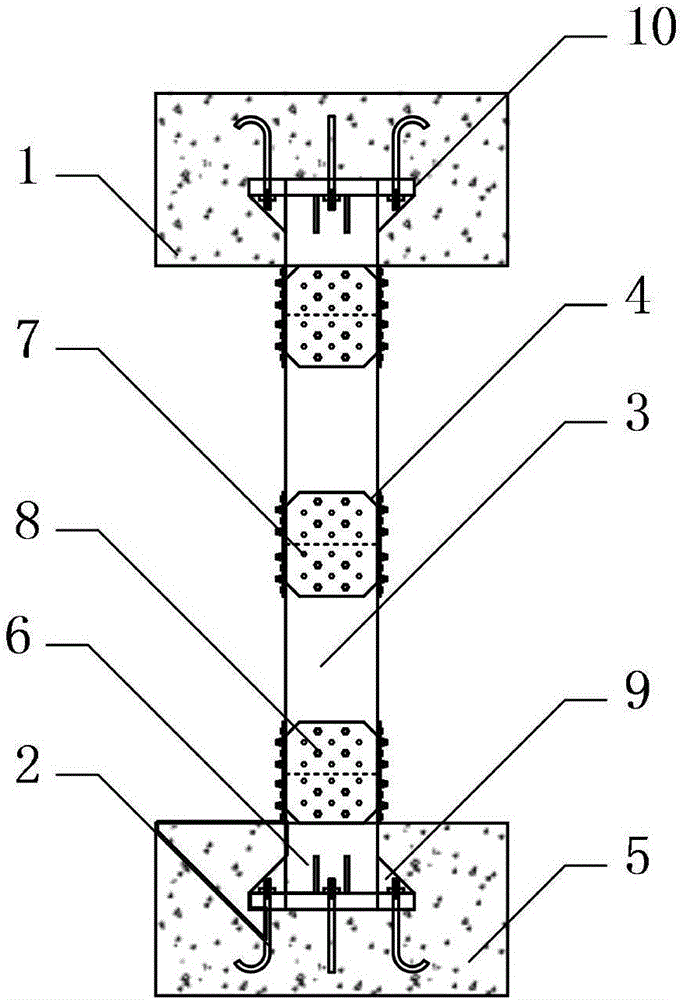

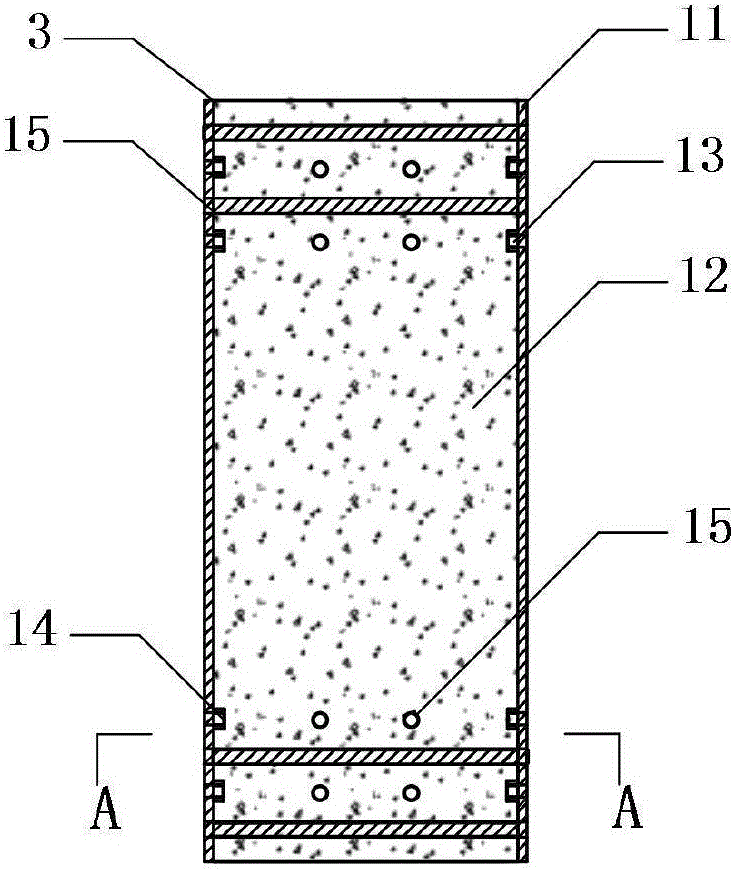

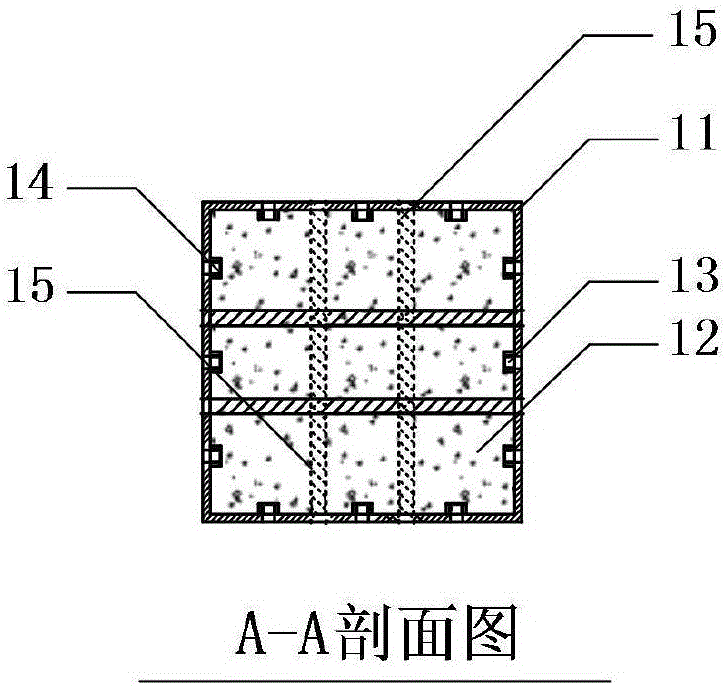

[0024] The following is attached Figure 2.1 - attached Figure 4 , to further describe the specific embodiments of the present invention.

[0025] Step 1: Processing the prefabricated steel pipe concrete segment (3), the connecting plate (4), and the embedded node (6), specifically including the following steps:

[0026] 1) Prefabricated steel pipe concrete section (3), the prefabricated steel pipe concrete section (3) is manufactured in the factory, the plates are welded into rectangular steel pipes, and the welds should be groove penetration welds. Process reserved bolt holes and core-through bolt holes on the steel pipe, align the preset nut (14) with the axis of the reserved bolt hole and then fix it by spot welding. The end of the nut that is not spot welded to the inner wall of the steel pipe is made of sealing material (14 ) for sealing, set the PVC pipe (15) at the position of the core bolt hole, pass the core bolt (8) through the PVC pipe (15) and tighten it for te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com