Method for installing pipeline scaffold of steel roof equipment and rigid suspended scaffold

A scaffolding and hanging type technology is applied in the field of method and rigid hanging type scaffolding, which can solve the problems of high cost, inability to operate the crane, and high construction cost, and achieve the effect of saving construction period and cost, saving scaffolding materials, and speeding up the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

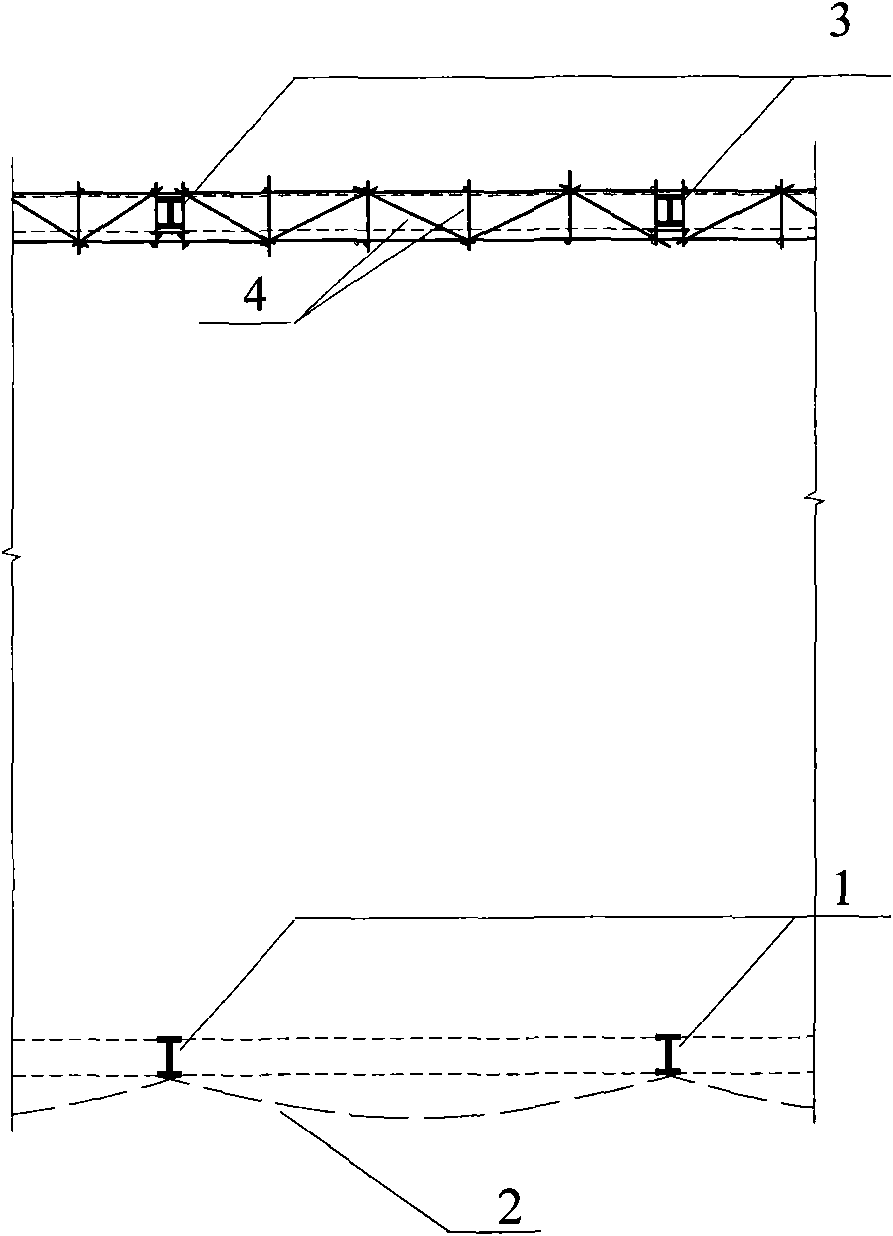

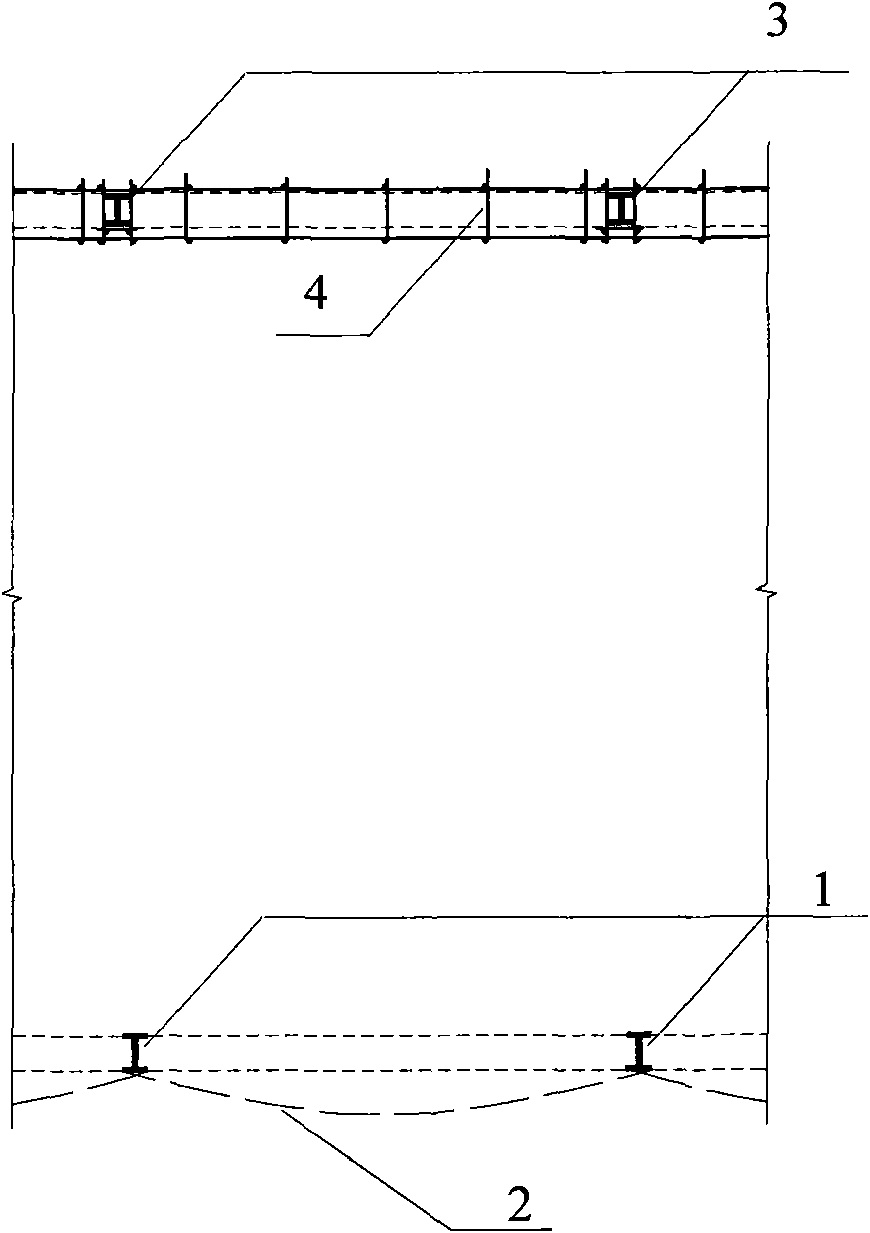

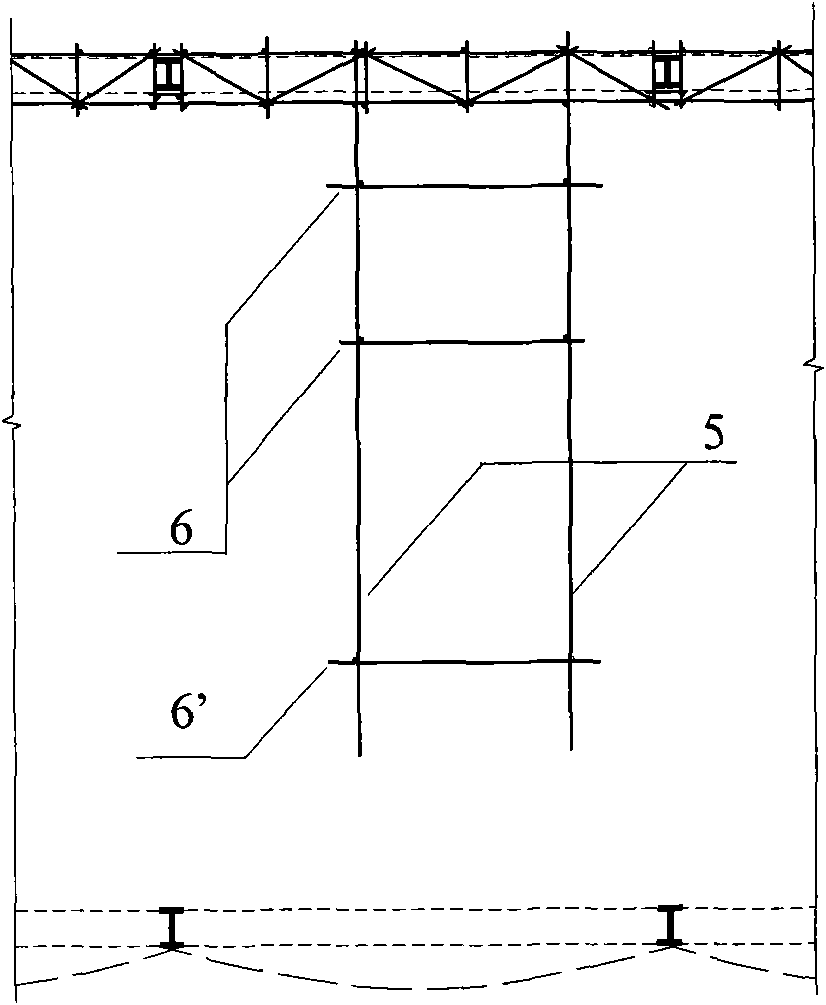

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

[0036] Such as Figure 1-Figure 12 As shown, the present invention forms a rigid hanging scaffold by multiple steel pipe upper trusses 4 of the same structure and multiple hanging scaffolds of the same structure; each steel pipe upper truss 4 is erected on the steel Between no less than two upper chords 3 of the roof, the upper trusses 4 of each steel pipe should be connected with each other to form a whole; each hanging scaffold is hung on each steel pipe along the direction of the equipment pipeline 14 Below the truss 4, the length of the "hanging air corridor" formed by the vertical connection between multiple hanging scaffolds is the same as the length of the corresponding equipment pipeline 14; the connection between the upper truss 4 of each steel pipe and each hanging scaffold The relationship is as follows:

[0037] 1) The upper, lower, left, and right members...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com