Construction process for pile slab type non-soil roadbed highway

A technology of construction technology and soil roadbed, which is applied in the direction of infrastructure engineering, roads, roads, etc., can solve the problems of large environmental impact, long construction period, waste of resources, etc., to improve project quality, shorten construction period, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

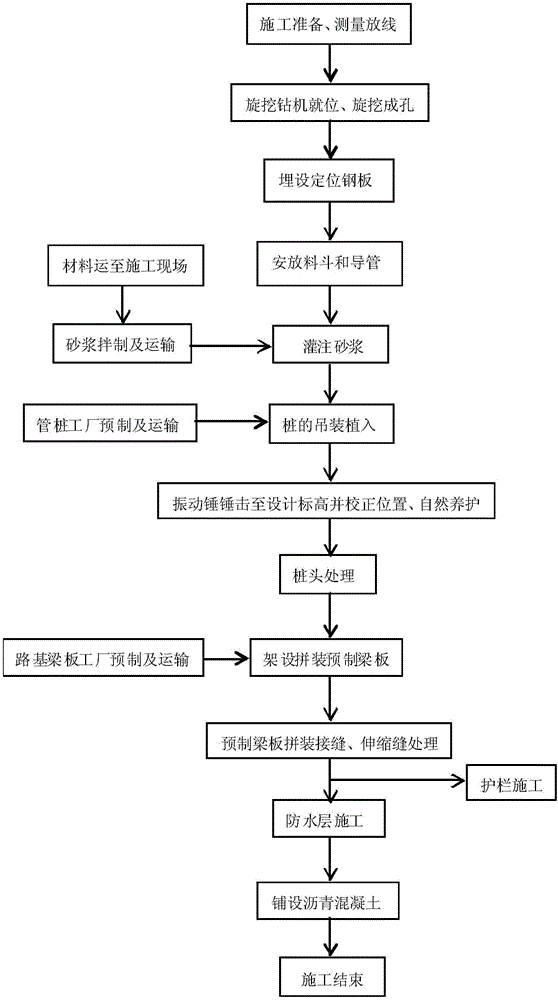

[0046] In order to clearly illustrate the technical characteristics of this solution, the solution will be further described below in conjunction with the accompanying drawings. The pile plate type soilless subgrade road construction technology of this scheme includes the following steps:

[0047] (1) Construction preparation, measurement and setting out: do all the preparatory work before construction, including personnel preparation, technical preparation, construction machinery and equipment and supporting equipment preparation, etc., level the construction site to provide a site for rotary drilling rigs and cranes; survey Set out the line to delineate the construction red line, the construction plane position and the elevation control point. The elevation of the pile hole and the depth of the hole are determined by level measurement, the plane position of the pile hole is determined by a total station, and the center of the pile hole is determined.

[0048] (2) The rotary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com