Polymer cement waterproof material and preparation method thereof

A waterproof material and polymer technology, applied in the field of building materials, can solve problems such as stability and curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

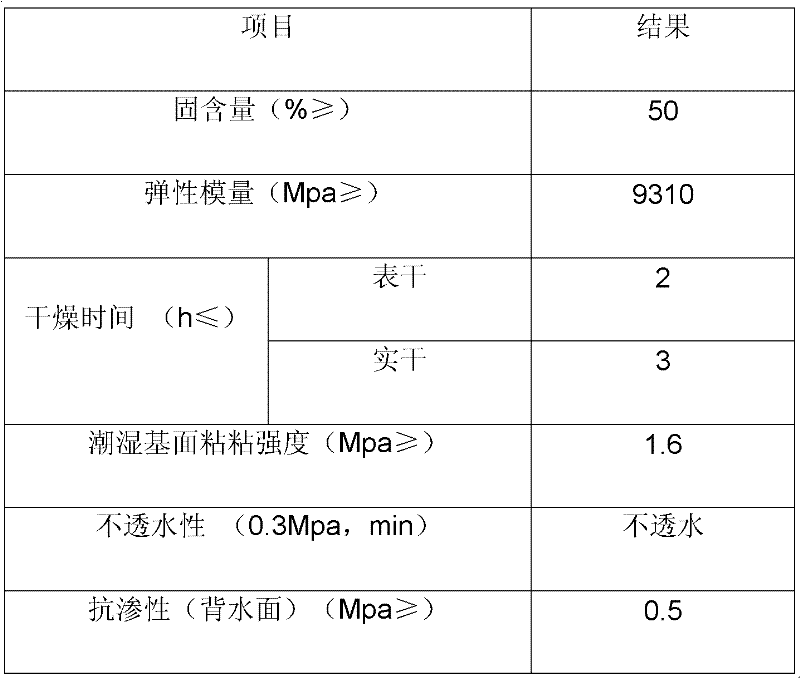

Examples

Embodiment 1

[0027] The ratio of polymer cement waterproof coating in this example is:

[0028] Portland cement 100 parts

[0029] Styrene acrylic emulsion and polyurethane emulsion 5 parts

[0030] 60 parts of fly ash

[0031] Polycarboxylate superplasticizer 0.5 parts

[0032] 2 parts polypropylene fiber

[0033] 60 servings of river sand

[0034] 200 parts of water

[0035] The Portland cement used is No. 42.5 ordinary Portland cement, and the fly ash is Class I fly ash.

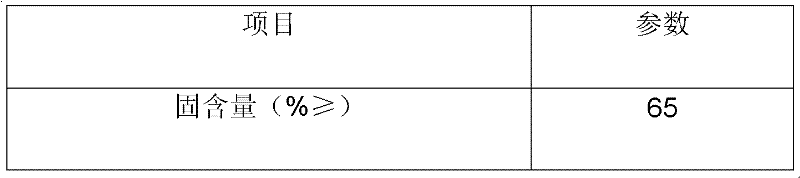

[0036] In styrene-acrylic emulsion and polyurethane emulsion, the weight ratio of polyurethane emulsion and styrene-acrylic emulsion is 2: 10, and the solid content of polyurethane emulsion is 35%, and the solid content of styrene-acrylic emulsion is 48%,

[0037] The cement used is ordinary Portland cement 42.5 from Shandong Shanshui Cement Group Co., Ltd.; the styrene-acrylic emulsion used is Changsha Libo Chemical Co., Ltd. The BC-139 glossy styrene-acrylic architectural emulsion produced; the polyurethane e...

Embodiment 2

[0046] The ratio of polymer cement waterproof coating in this example is:

[0047] Portland cement 100 parts

[0048] 8 parts of styrene-acrylic emulsion and polyurethane emulsion

[0049] Fly ash 55 parts

[0050] Naphthalene sulfonate superplasticizer 1 part

[0051] carbon fiber 3 parts

[0052] 90 pieces of river sand

[0053] 210 parts of water

[0054] The Portland cement used is No. 42.5 ordinary Portland cement, and the fly ash is Class I fly ash.

[0055] In the styrene-acrylic emulsion / polyurethane emulsion, the weight ratio of the polyurethane emulsion to the styrene-acrylic emulsion is 1:10, the solid content of the polyurethane emulsion is 35%, and the solid content of the styrene-acrylic emulsion is 48%.

[0056] The cement used is ordinary Portland cement 42.5 from Shandong Shanshui Cement Group Co., Ltd.; the styrene-acrylic emulsion used is Changsha Libo Chemical Co., Ltd. The BC-139 glossy styrene-acrylic architectural emulsion produced; the polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com