O-shaped steel bar connecting structure

A technology for connecting structures and steel bars, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of missing key structures, heavy workload, and lagging control structures, and simplify the connection of steel bars and component joints. , The effect of reducing the project cost and reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

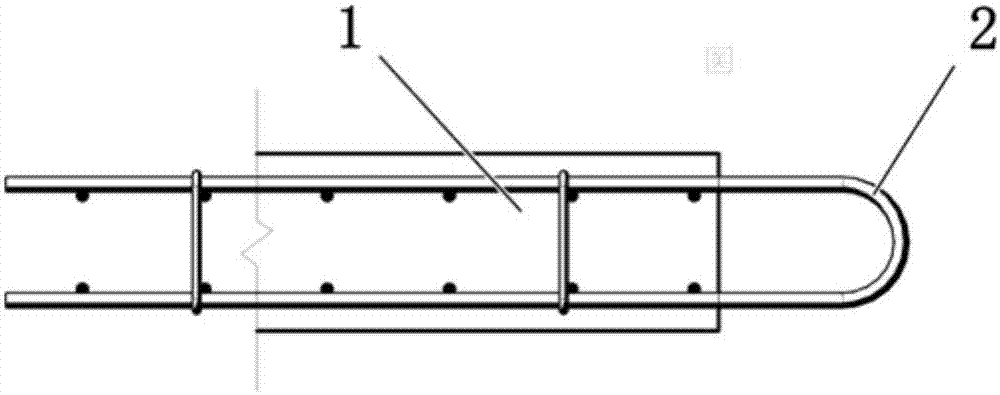

[0022] Such as figure 2 , Prefabricated concrete component 1, 24cm thick, with U-shaped steel bar 2 at the end, the connection of U-shaped steel bar 2 is welded, and the wet joint width of the connection is 50cm, the workload is too large, and the construction efficiency is low.

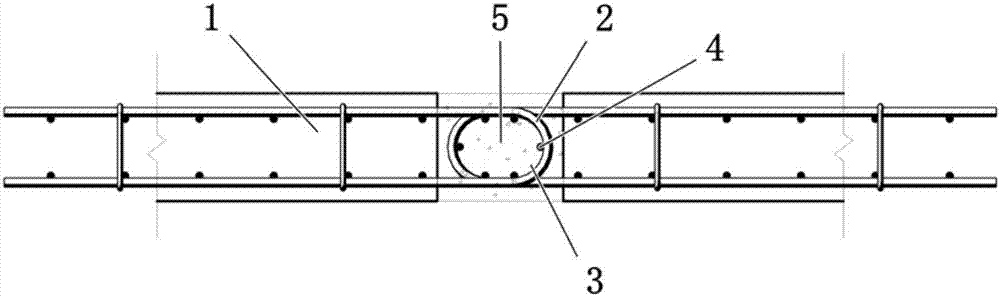

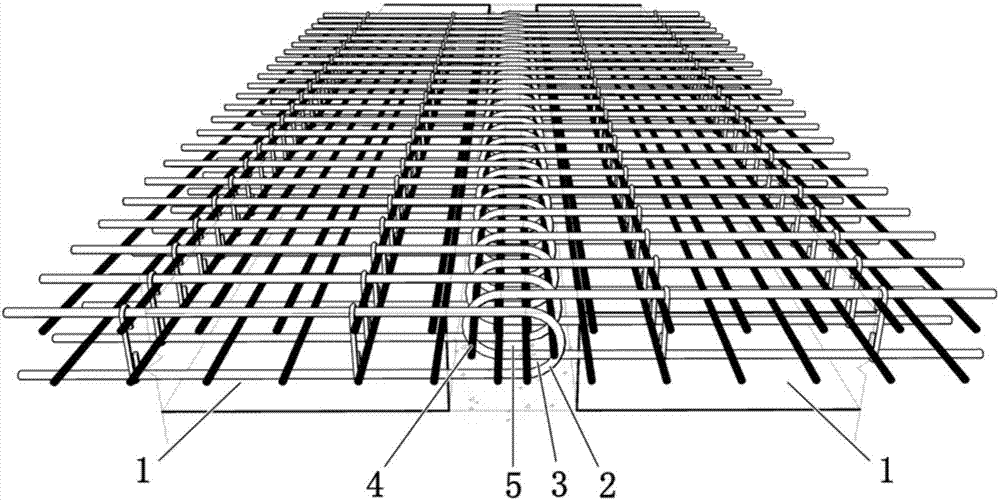

[0023] Such as figure 1 , image 3 Two rows of U-shaped steel bars 2 arranged on different prefabricated concrete components 1 are overlapped and intersected to form an O-shaped steel bar structure 3. The support pad steel bar 4 is arranged in the O-shaped steel bar structure 3, and the anchor is formed by pouring pressure-bearing concrete 5 The two rows of opposite U-shaped steel bars 2 are not welded, and they are intersected with each other, with a distance of 7.5 cm. The supporting steel bars 4 are arranged in the O-shaped steel bar structure 3 and bound to it, and the O-shaped steel bar structure 3 is connected in series. One piece, forming a net-shaped force-bearing surface, the diameter of ...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1. The distance between the supporting steel bars used is 40 mm, and the diameter is 12 mm. They are arranged symmetrically on the O-shaped steel bars. The distance between the U-shaped steel bars is 75 mm. The axial center of the bearing concrete The standard value of compressive strength is 35Mpa.

Embodiment 3

[0028] This embodiment is basically the same as Embodiment 1. The distance between the supporting steel bars used is 150 mm, and the diameter is 25 mm. They are arranged symmetrically on the O-shaped steel bars. The distance between the U-shaped steel bars is 100 mm. The standard value of compressive strength is 40Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com