Industrial construction method for multistory residence system with clamp die frame core wall self-bearing structure

A construction method and self-supporting technology, applied to walls, building components, building structures, etc., can solve the problems of poor seismic capacity of concrete load-bearing walls, difficulty in ensuring engineering quality, and poor overall rigidity of walls, etc., and achieve noise reduction performance And the effect of improving mechanical properties, less investment in production equipment, saving formwork materials and steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

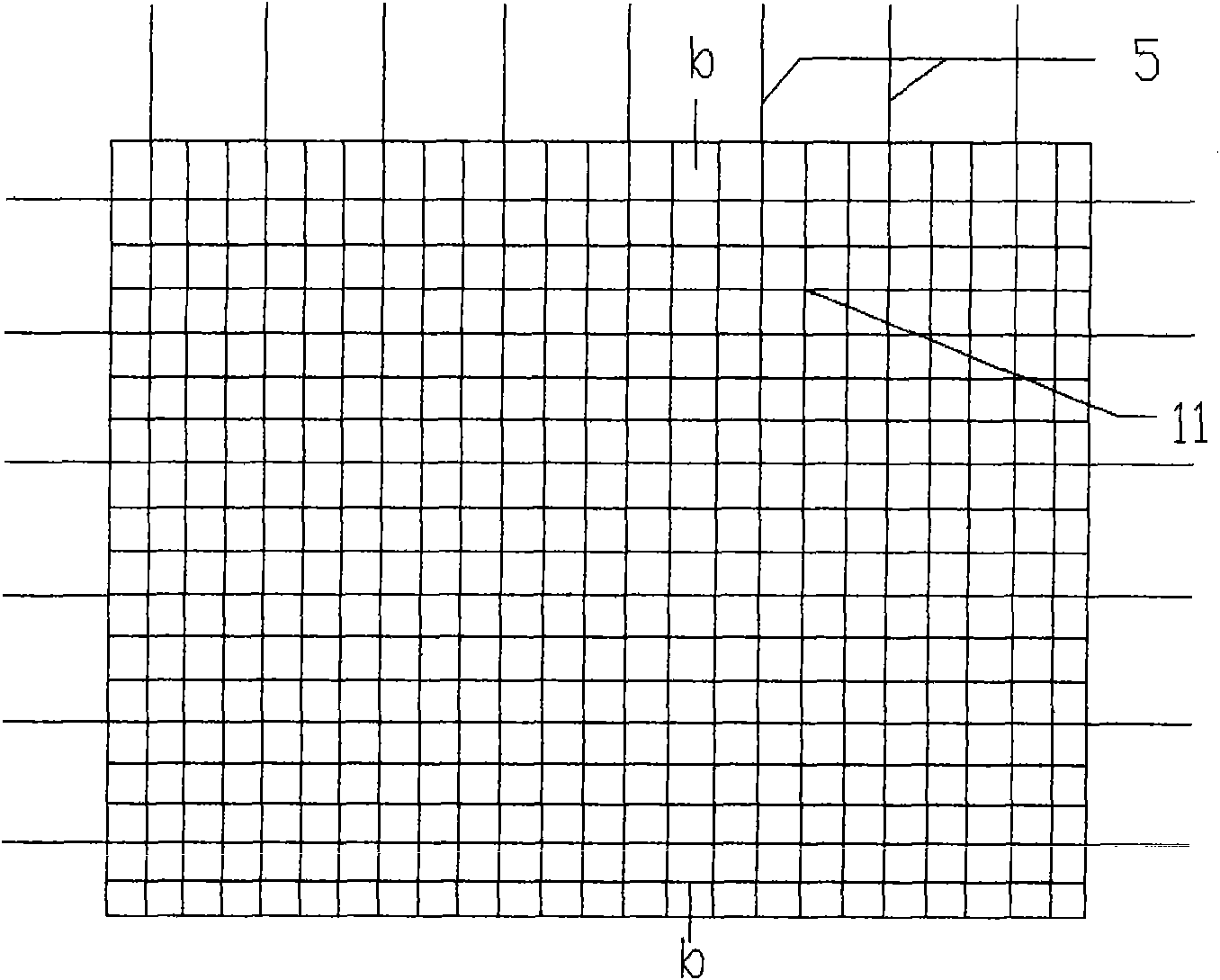

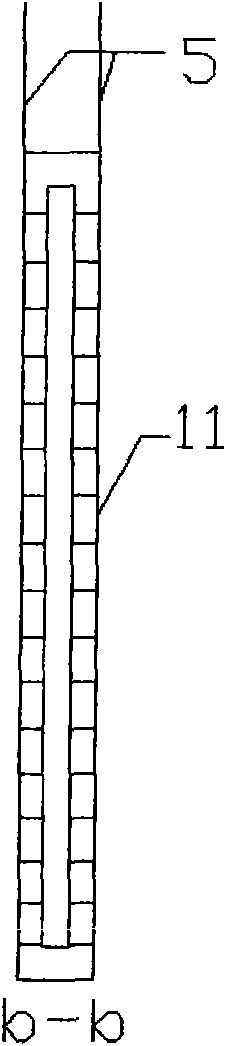

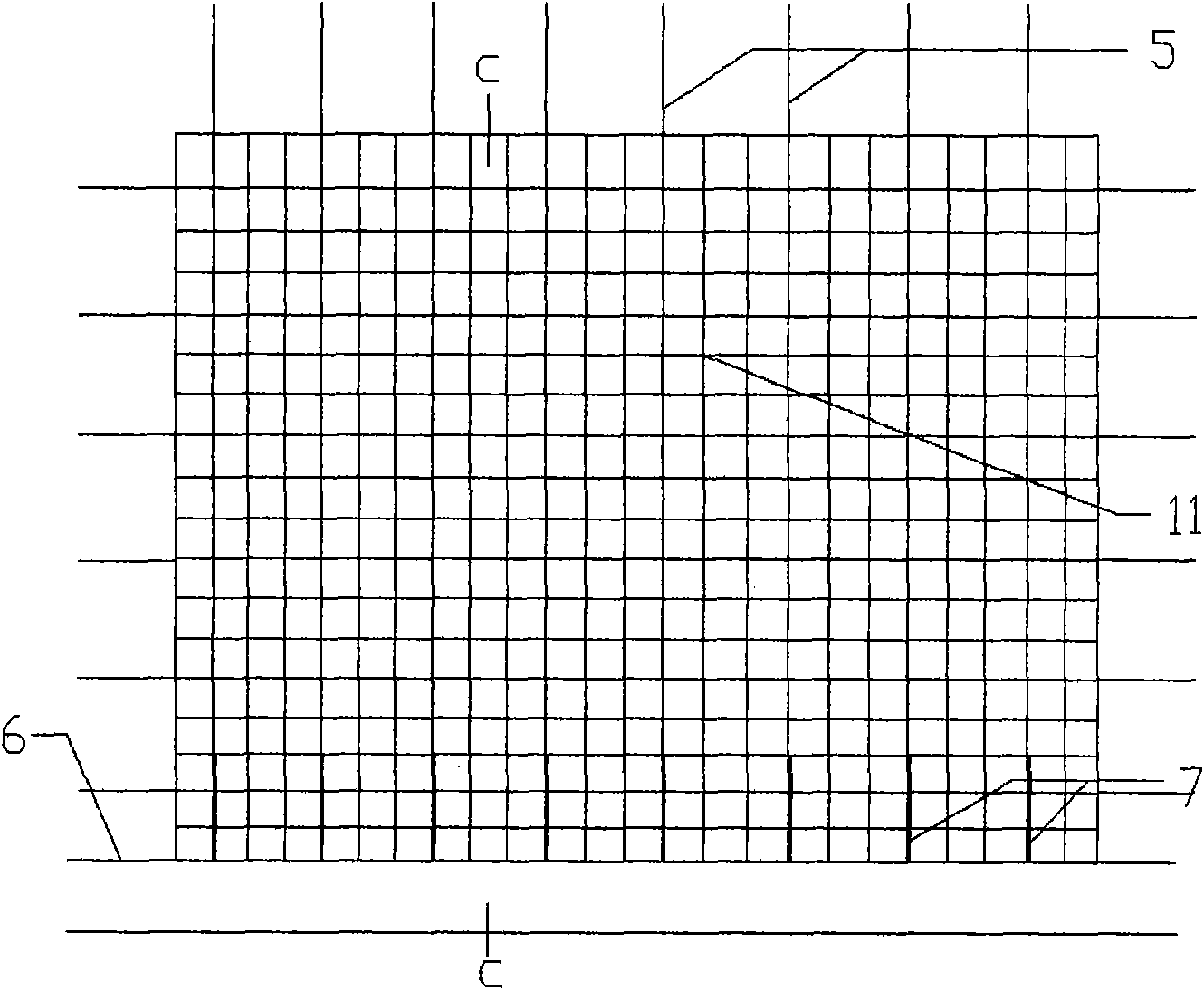

[0043] Steel mesh light board sandwich slabs are used as prefabricated wall panels, such as Figure 1-9 As shown, firstly, at the construction site, the pre-embedded connecting steel bars 7 on the load-bearing wall foundation and the concrete foundation beam 6 and the pre-embedded longitudinal steel bars 23 on the structural columns are completed.

[0044] According to the design, install the steel mesh light board sandwich blank 11 between the connecting steel bars pre-embedded in the foundation beam, align, support, and bind firmly (participate image 3 , 4 ). Make preparations for construction, including setting up single-row scaffolding and operating platforms and appropriate environmental protection measures, trial operation of on-site spraying equipment, trial preparation of sprayed concrete, so that the concrete mix ratio, consistency, adhesion, compactness, etc. meet the quality requirements .

[0045] Configure the reinforced steel bars 21 for the structural column...

Embodiment approach 2

[0055] When multiple prefabricated steel mesh light slab sandwich concrete slabs are used (the cross-section is as follows Figure 11 When the wallboards assembled as shown) are assembled, the construction method adopted is basically the same as that of Embodiment 1, the difference is that the connecting column 4 is poured on site between the adjacent two steel mesh light board sandwich concrete slabs. connection (see Figure 12 ). The steel mesh light slab sandwich concrete slab is prefabricated in a factory, and the prefabrication process is formed by pouring concrete layers 13 on both sides of the steel mesh light slab sandwich slab 11 .

[0056] The thickness of the concrete layer 13 may be 30-50mm, preferably 35mm, 40mm or 50mm. One side of the steel mesh light board sandwich concrete slab can also be prefabricated with an insulation layer.

[0057] During the construction process, the edge of the assembled steel mesh light board sandwich concrete slab (that is, the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com