Industrial construction method of building

A construction method and building technology, applied in the direction of building structure, building material processing, construction, etc., can solve the problems of high noise in the mixing process, difficulty in ensuring high quality, and high construction difficulty, so as to speed up the construction progress, improve efficiency and The effect of improving quality, reducing engineering cost and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

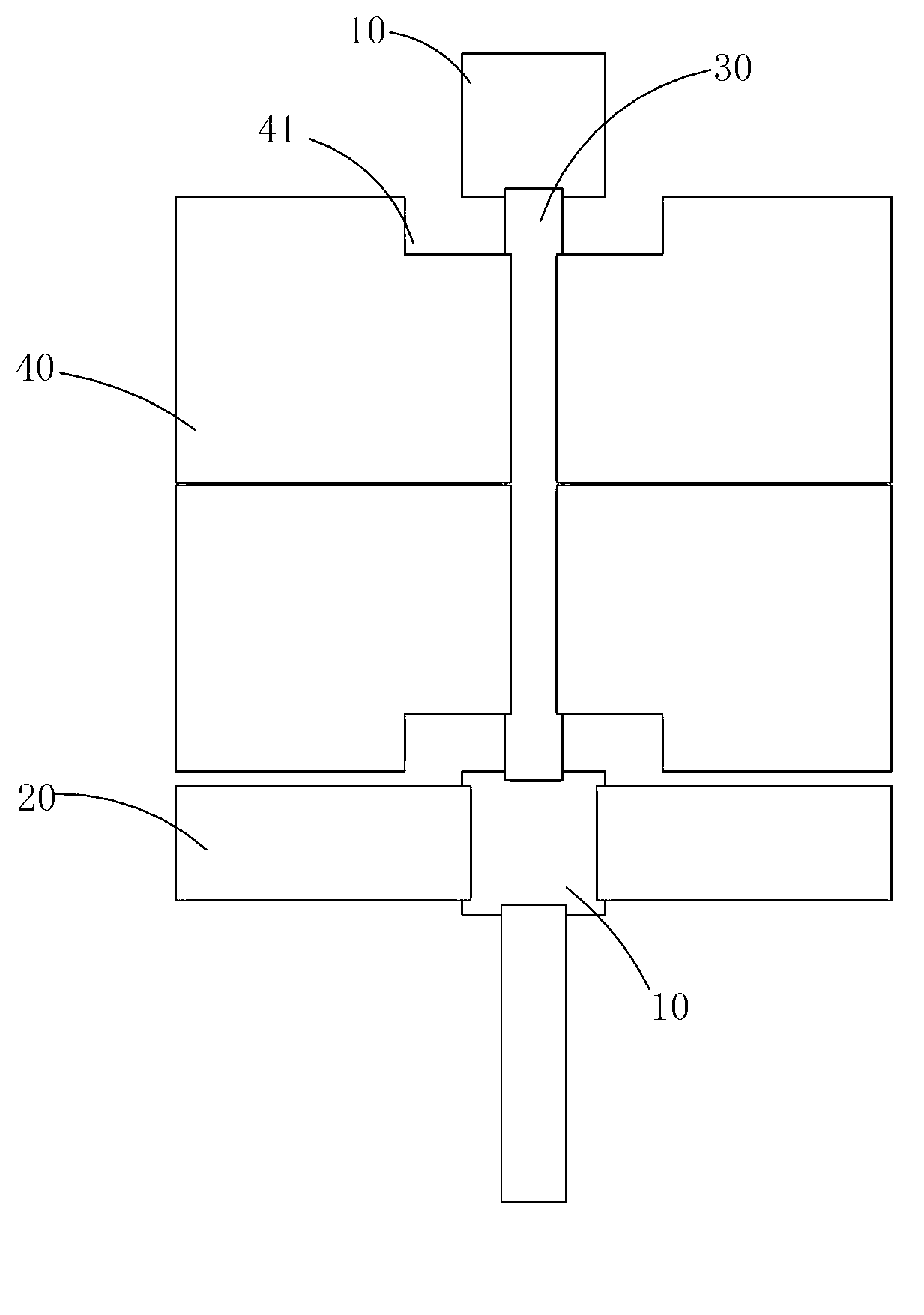

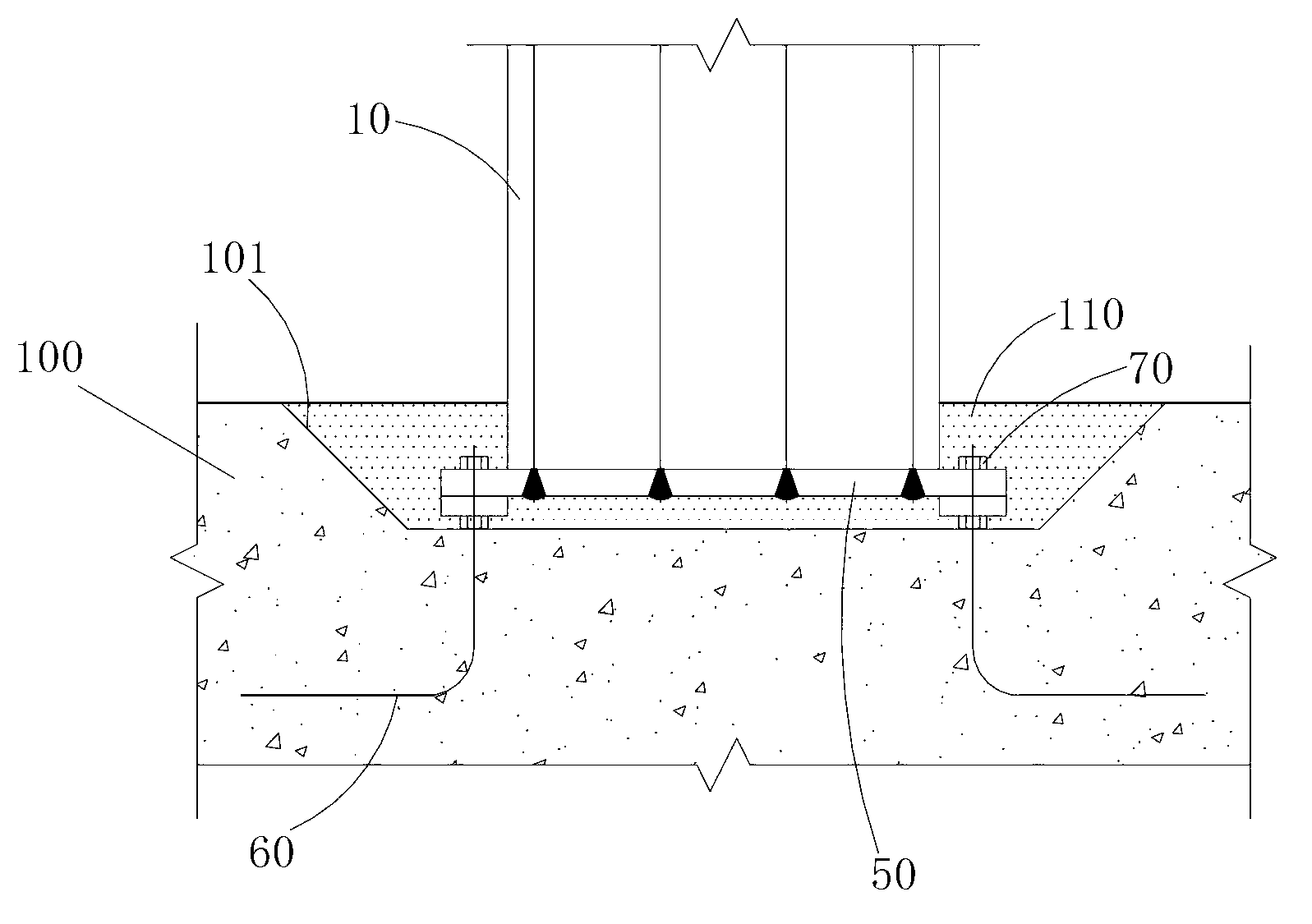

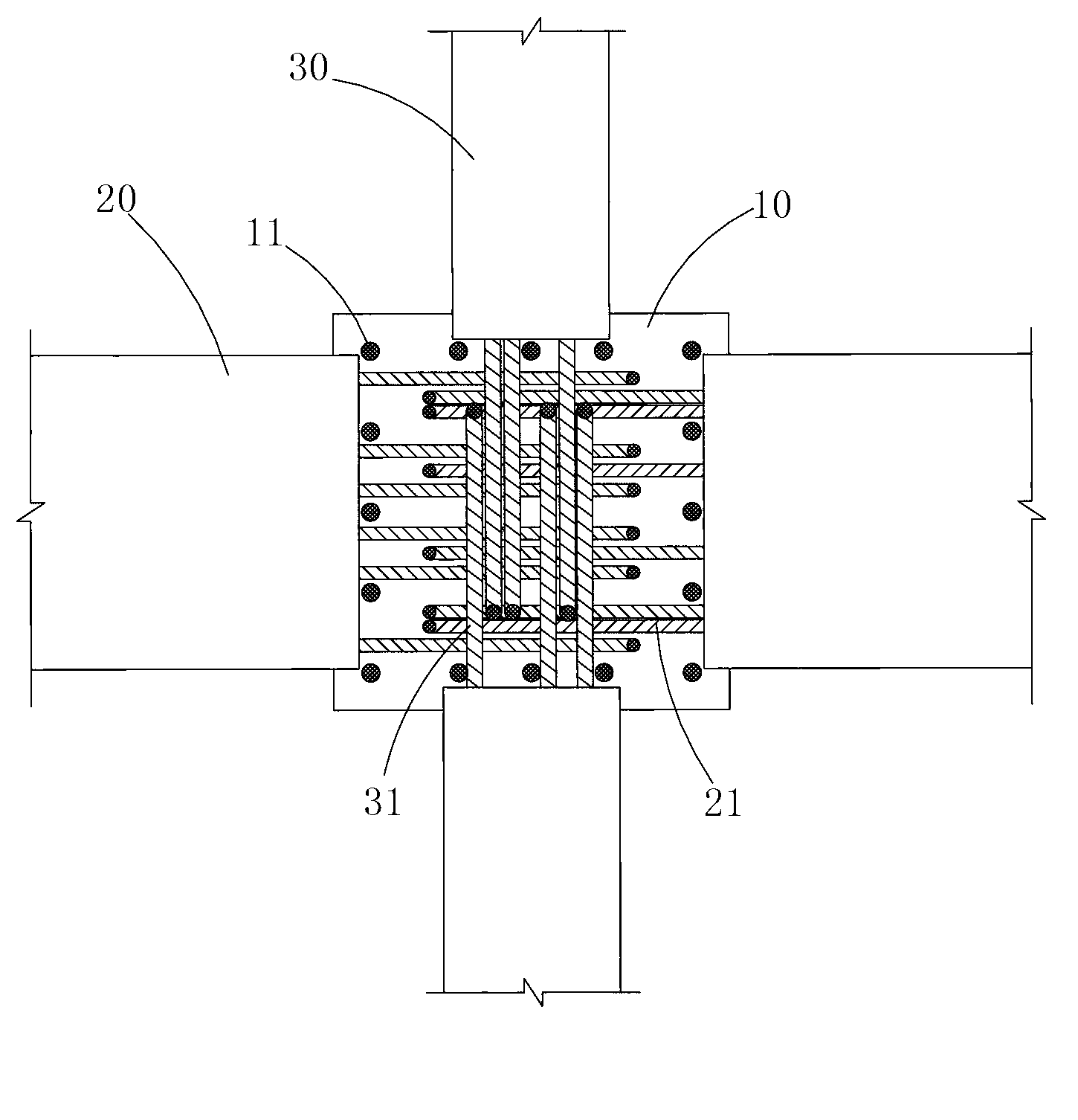

[0031] reference Figure 1-3 , The industrial construction method of a building according to an embodiment of the present invention includes the following steps:

[0032] S1. Prefabricated prefabricated parts including prefabricated columns 10, prefabricated beams, prefabricated floor slabs 40 and prefabricated exterior walls (not shown), wherein the prefabricated beams include a main beam 20 and a secondary beam 30.

[0033] The prefabricated parts are industrially produced according to the requirements. The production adopts steel molds. The produced prefabricated parts have accurate dimensions and smooth surface, so that there is no need to batch and shake at the construction site. The prefabricated parts are transported to the construction site for installation during use, which can reduce construction The number of high-altitude workers on site reduces the probability of work injuries, and reduces noise and environmental pollution at the construction site, making it more envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com