Thawing method for frozen meat

A technology for freezing meat and meat, which is applied in the fields of separation methods, preservation of meat/fish by freezing/cooling, chemical instruments and methods, etc., can solve the loss of protein nutrients, the surface of meat is easily contaminated by bacteria, and the thawing time of frozen meat is long. and other problems, to achieve the effect of saving water, working closely and easy to control, and the process method is environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

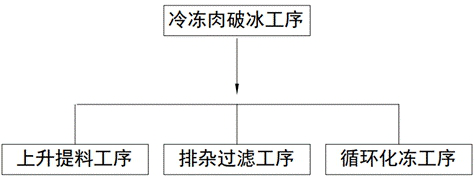

[0066] like figure 1 As shown, a method for thawing frozen meat includes an ice-breaking process, a material lifting process, a filtering process, and a circulation process, and is characterized in that the material lifting process includes:

[0067] Step 1, frozen meat ice-breaking process, first place the frozen meat 100 on the lifting mechanism 3 in the thawing chamber 1, and then the second driving mechanism 6 drives the knocking assembly 21 to start exposing the frozen meat 100 on the lifting mechanism 3 to the water The part of the square is knocked, and the ice cubes 200 and the meat grains 300 on the outer surface of the frozen meat 100 are knocked off;

[0068] Step 2, lifting and lifting process. When the outer surface of the frozen meat 100 has completed part of the thawing work, the first driving mechanism 5 drives the lifting mechanism 3 to lift, and the upper part of the new frozen meat 100 to be thawed is exposed on the water surface. Drive the ice breaking mec...

Embodiment 2

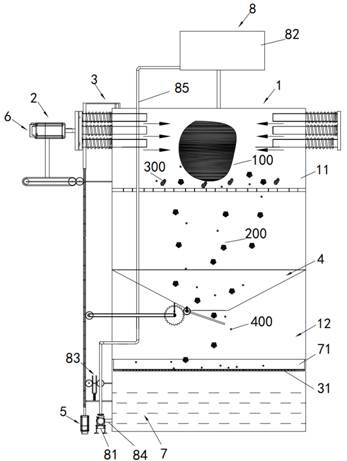

[0082] like figure 2 As shown, a rapid thawing device for frozen meat products includes a thawing bin 1, and the thawing bin 1 includes a thawing area 11 and a filtering area 12;

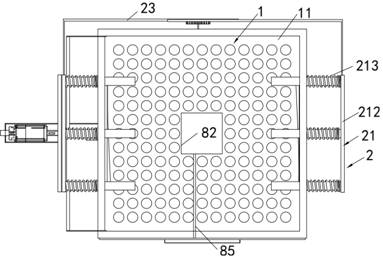

[0083] In the defrosting area 11, an ice breaking mechanism 2, a material lifting mechanism 3 and a miscellaneous discharge mechanism 4 are successively arranged in the vertical direction. Under the synchronous transmission;

[0084] The ice breaking mechanism 2 knocks the frozen meat products on the lifting mechanism 3 through the second driving mechanism 6, and the falling ice cubes 100 and slag 200 are output and collected under the action of the trash removal mechanism 4;

[0085] A filtration circulation mechanism 7 is arranged in the filtration area 12;

[0086] The filtration circulation mechanism 7 guides the water in the filtration area 12 into the water storage mechanism 8 and is used for continuously defrosting the frozen meat products in the first defrosting area 11 .

[0087] In thi...

Embodiment 3

[0121] The components in this embodiment that are the same as or corresponding to those in the above embodiment use the corresponding reference numerals. For the sake of simplicity, only the differences from the above embodiment will be described below. The difference between this embodiment and the above-mentioned embodiment is:

[0122] further, such as figure 2 As shown, the filtration circulation mechanism 7 includes a filter bin 71, which is arranged at the lower end of the miscellaneous discharge mechanism 4, and is used for performing secondary filtration on the debris discharged from the miscellaneous discharge mechanism 4. The aperture of the filter chamber 71 is smaller than the aperture of the filter plate 31 , and the filter chamber 71 is arranged in the defrosting chamber 1 in a pull-out manner.

[0123] In this embodiment, by setting the filter bin 71 to cooperate with the filter circulation mechanism 7, the small ice and impurities in the water discharged by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com