Continuous minced fillet production system and method for preparing minced fillets

A production system, surimi technology, applied in fish processing, fish cleaning/descaling, slaughtering, etc., can solve problems such as negative impact on surimi quality, denaturation of fish meat salt-soluble protein, manual adjustment, etc., to reduce the number of equipment used and The equipment occupies an area, reduces texture damage and protein denaturation, and reduces the effect of fiber state damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

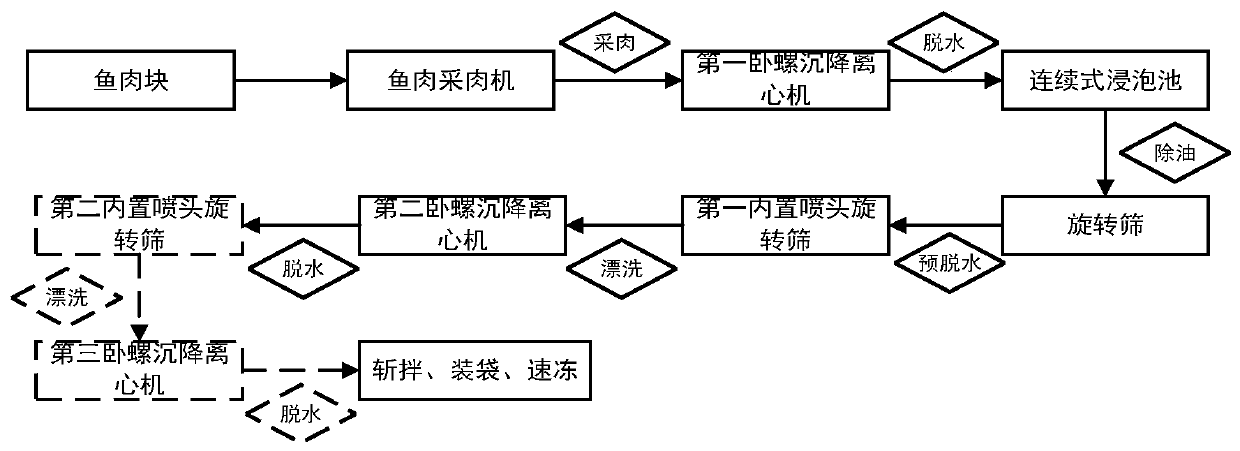

[0042] The present embodiment provides a continuous surimi production system, such as figure 1 As shown, the system includes a sequentially connected fish miner, the first decanter sedimentation centrifuge, a continuous soaking tank, a rotary screen, the first built-in nozzle rotary screen, the second decanter sedimentation centrifuge, and post-processing equipment ;

[0043] The fish meat miner is used to separate the bone spurs and skin of the fish meat to obtain an aqueous solution of fish meat; the first decanter decanter centrifuge is used to remove water-soluble substances and blood water from the fish meat aqueous solution to obtain fish meat solids; The continuous immersion tank is used to remove the grease in the fish solids; the rotary sieve is used to pre-dehydrate the degreased fish; the first built-in nozzle rotary sieve is used to rinse the pre-dehydrated fish The second decanter decanter centrifuge is used to remove water from the fish after rinsing; the post-p...

Embodiment 2

[0068] Utilize the continuous type surimi production system to carry out the surimi processing method that specification is 400g-800g / tail seawater miscellaneous fish, described method comprises:

[0069] Step 1: the fish meat pieces are processed by a fish meat miner to separate bone spurs and fish skins to obtain an aqueous solution containing fish meat;

[0070] Step 2: The aqueous solution containing fish meat is dehydrated through the first decanter decanter centrifuge, and the first decanter decanter centrifuge adopts a single-head decanter decanter centrifuge with a length-to-diameter ratio of 2.5 to obtain a water content of 80%- 85% fish solids;

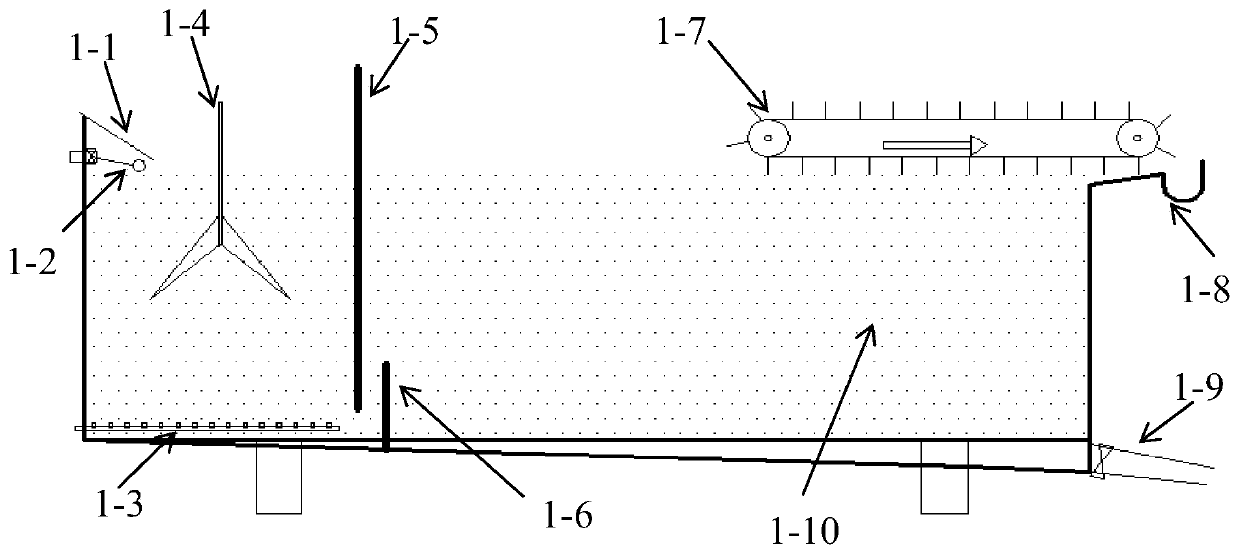

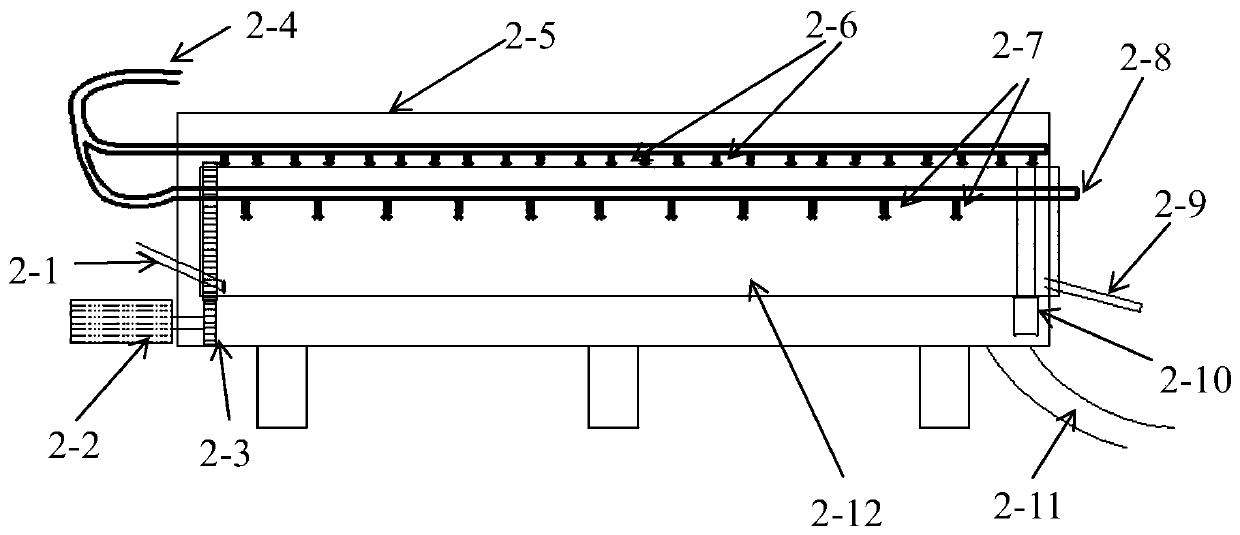

[0071] Step 3: remove the grease in the fish meat solids in the continuous immersion tank, set the distance between the deflector 1-6 and the oil separator 1-5 in the continuous immersion tank to be 25cm, and the height of the deflector 1-6 is 45cm; Control the flow time of the fish solids from the fish solids inlet 1-1 to ...

Embodiment 3

[0075] Utilize continuous type surimi production system to carry out surimi processing method to the silver carp that specification is 1000g-1500g / tail, described method comprises:

[0076] Step 1: the fish meat pieces are processed by a fish meat miner to separate bone spurs and fish skins to obtain an aqueous solution containing fish meat;

[0077] Step 2: The aqueous solution containing fish meat is dehydrated through the first decanter decanter centrifuge, and the first decanter decanter centrifuge adopts a single-head decanter decanter centrifuge with an aspect ratio of 3.5 to obtain a water content of 80%- 85% fish solids;

[0078] Step 3: remove the grease in the fish meat solids in the continuous immersion tank, set the distance between the deflector 1-6 and the oil separator 1-5 of the continuous immersion tank to be 30cm, and the height of the deflector 1-6 to be 40cm; Control the flow time of the fish solids from the fish solids inlet 1-1 to the fish pulp discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com