Sheet metal part straightening device

A sheet metal part and straightening technology, applied in the field of sheet metal parts, can solve the problems of long time-consuming repair of sheet metal parts, deformation of sheet metal parts, and large labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

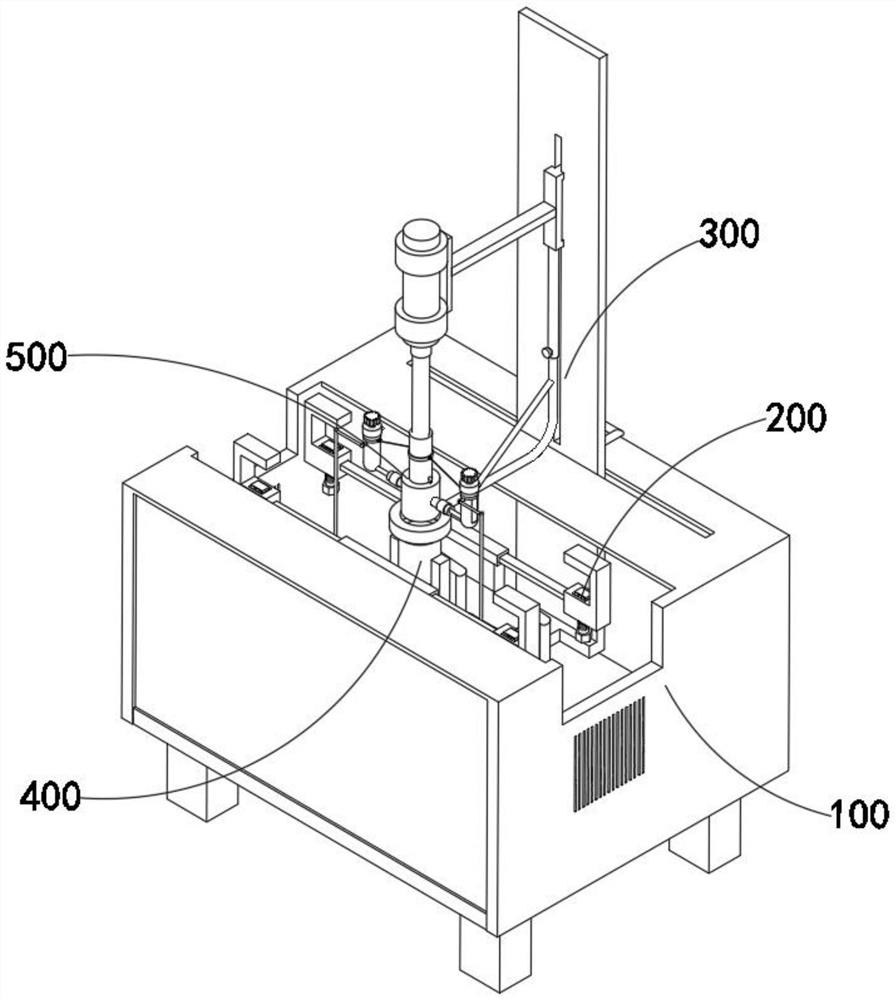

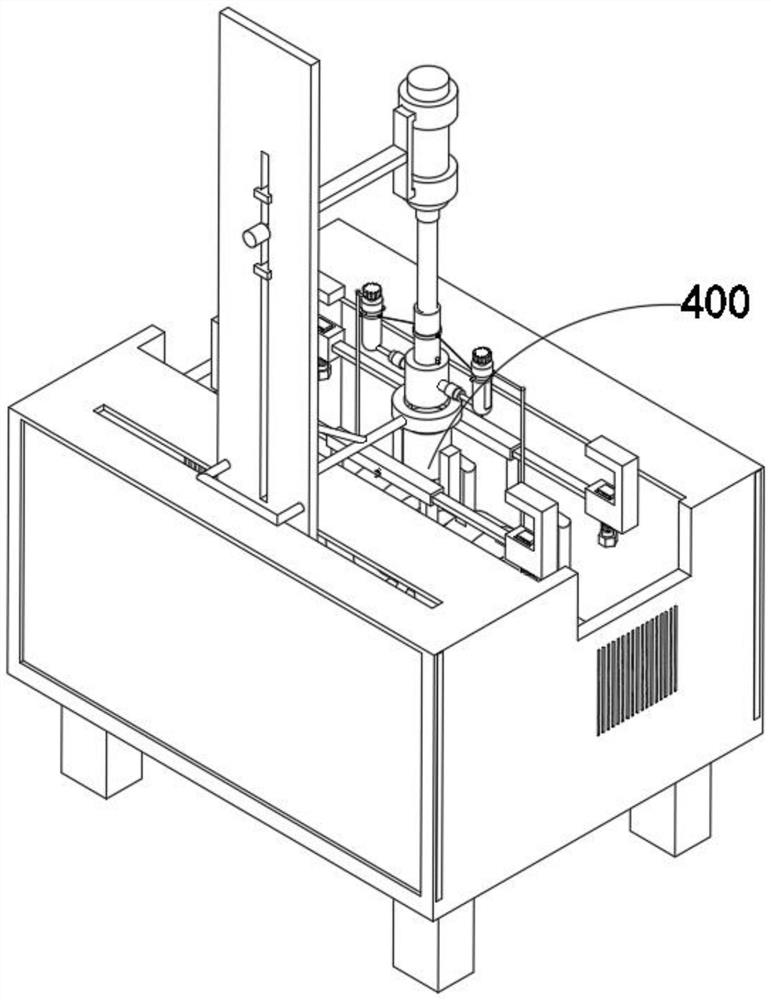

[0052] combine image 3 , 5 , 7, 8, 10 and 11, the sheet metal straightening device provided by the present invention includes a protection combination 100, a limit clamping mechanism 200, a traverse control assembly 300, a turbine power mechanism 400 and a heating mechanism 500, wherein , the limit clamping mechanism 200 is fixedly installed on the bracket 120 inside the protection assembly 100, and the traverse control assembly 300 is movably installed in the protection assembly 100, and the turbine power mechanism 400 is installed on the base 320 inside the traverse control assembly 300 , in addition, the heating mechanism 500 is installed in the vertical stabilizer 330 inside the traverse control assembly 300 .

[0053] The protective combination 100 includes a chassis shell 110 and a bracket 120, and the limit clamping mechanism 200 includes a base 210, a first slider 220, a second slider 230, a rocker 240, a pressing block 250, a pad assembly 260 and an elastic pressing...

Embodiment 2

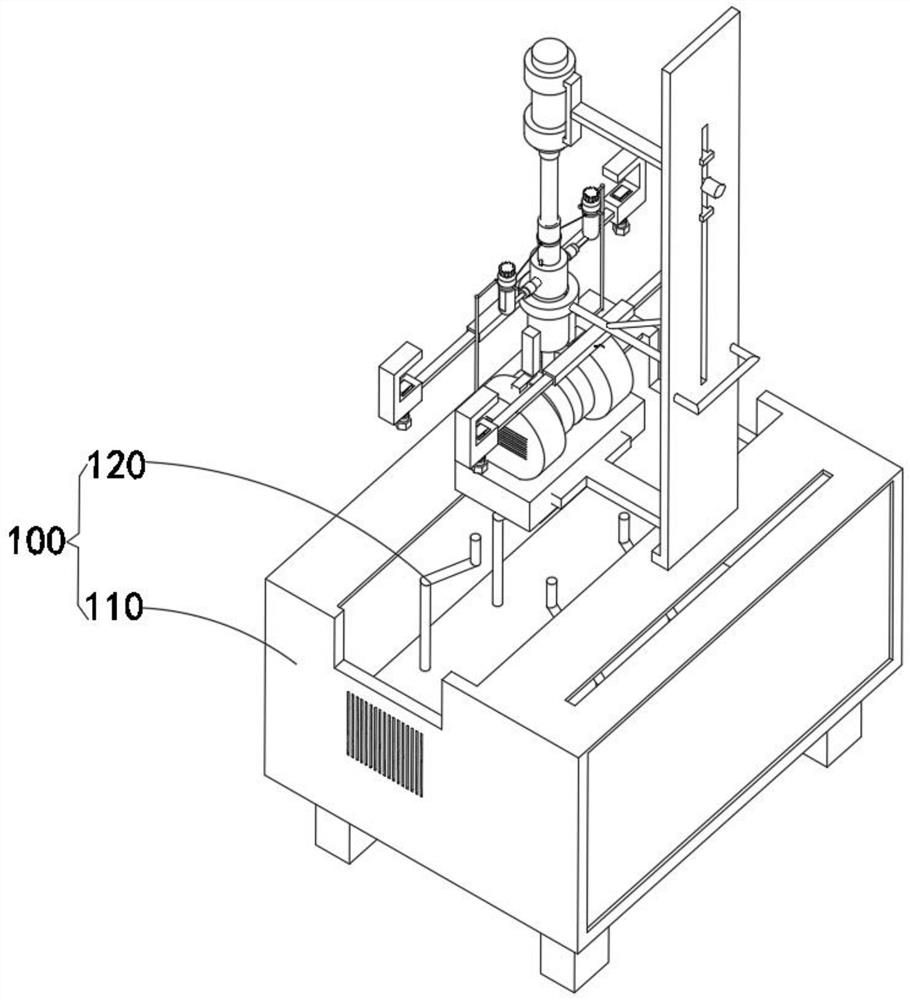

[0058] combine image 3 As shown, in the above embodiment, the chassis shell 110 is made of a hollow stainless steel plate, and at the same time, the heat-insulating paint is evenly applied on the outside, so as to ensure that the operator can discharge hot steam during the repair process of the sheet metal parts. Without affecting the work of the operator, the protective combination 100 includes a chassis shell 110 and a bracket 120 installed at the bottom of the inner cavity of the chassis shell 110 , and a chute is built in the bottom of the inner cavity of the chassis shell 110 .

Embodiment 3

[0060] combine Figure 7 As shown, in the above embodiment, the base 320 and its bottom slider are adapted along the chute in the inner cavity of the chassis shell 110, thereby ensuring that the device can be aligned with the sheet metal parts for large-scale repair work, and at the same time The bottom of the vertical stabilizer 330 is fixed with a telescopic compression piece 340, and the ring gasket at the bottom of the telescopic compression piece 340 is used to focus on the bulge of the sheet metal, so that the device can accurately repair the sheet metal, and the traverse control assembly 300 It includes a slide plate 310 located in the chassis shell 110, a base 320 installed on the protrusion at the bottom end of the slide plate 310, a vertical stabilizer 330 connected to the inner chute of the slide plate 310 through a screw, and a telescopic extension installed at the bottom of the vertical stabilizer 330. Compression piece 340 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com