Rotating drying cylinder

A technology of drying cylinder and outer cylinder, applied in drying, drying machine, drying solid materials, etc., can solve problems such as affecting the normal transportation of materials, decomposing toxic gas of sticky blocks, etc., to prevent continued deposition, prevent adhesion, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

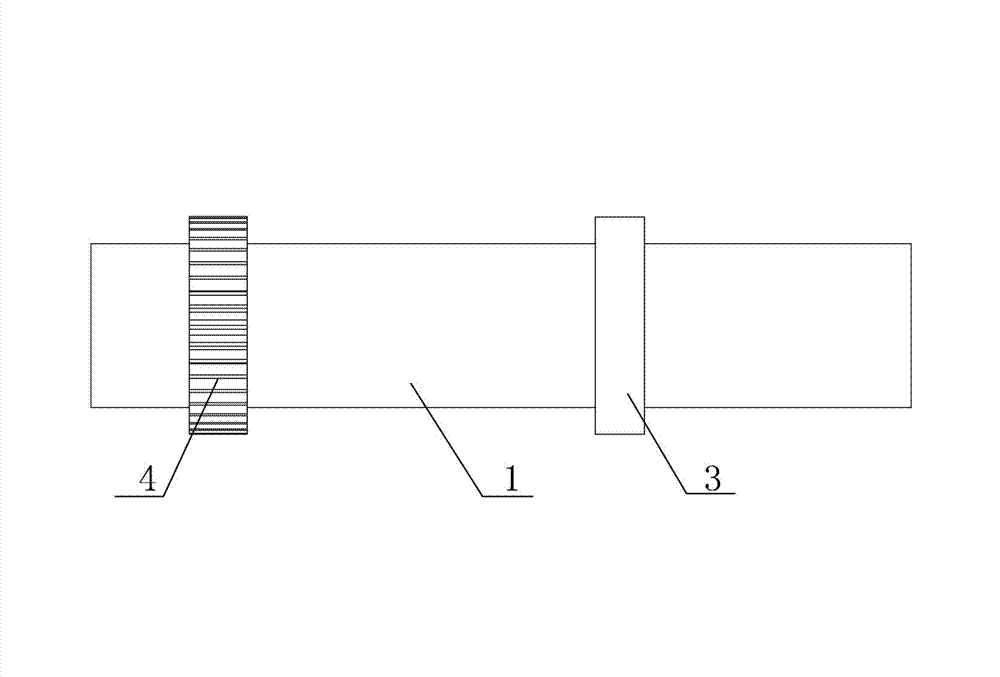

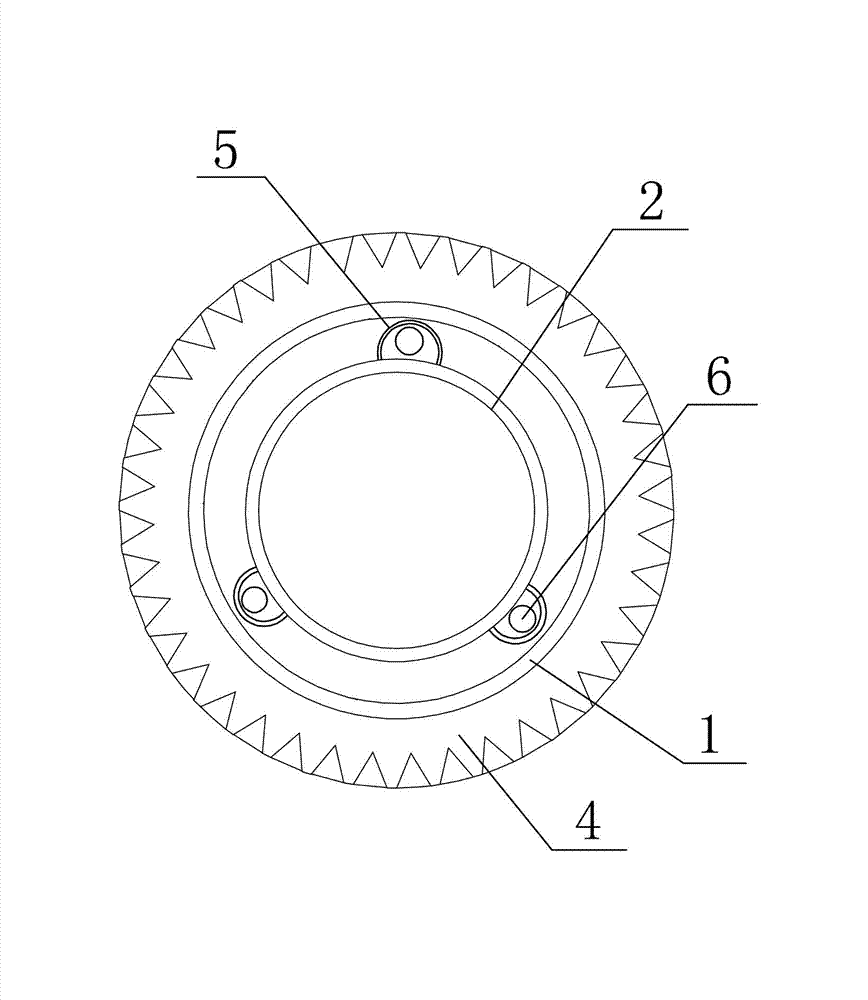

[0012] Embodiment 1: refer to figure 1 , figure 2 , a rotary drying cylinder, including an outer cylinder 1 arranged obliquely, an inner cylinder 2 built in the outer cylinder 1, a heating channel is formed between the inner cylinder 2 and the outer cylinder 1, and a roller is fixed on the outer circle of the outer cylinder 1 ring 3 and ring gear 4. The rotary drying cylinder is arranged on a supporting frame, on which a rolling ring seat and a ring gear seat are installed, the rolling ring seat meshes with the rolling ring 3 , and the ring gear seat meshes with the ring gear 4 . When the drying cylinder is in use, it is placed obliquely. The higher end of the outer cylinder 1 of the drying cylinder is the feed end, the lower end is the discharge end, and the higher end of the outer cylinder 1 is connected to the heater.

[0013] The outer wall of the inner cylinder 2 is fixed with a raised strip vibrating belt 5 along the axis, such as figure 2 There are three vibrating ...

Embodiment 2

[0014] Embodiment 2: The difference from Embodiment 1 is that a raised spiral vibrating belt is fixed along the axis on the outer wall of the inner cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com