Rutting plate specimen compaction instrument and compaction method

A rutting board and compaction instrument technology, which is applied in the preparation, sampling, and instrumentation of test samples, can solve the problems of insufficient hitting strength, easy to burn palms, uneven hitting, etc., to achieve uniform hitting and avoid scalding. , Improve the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

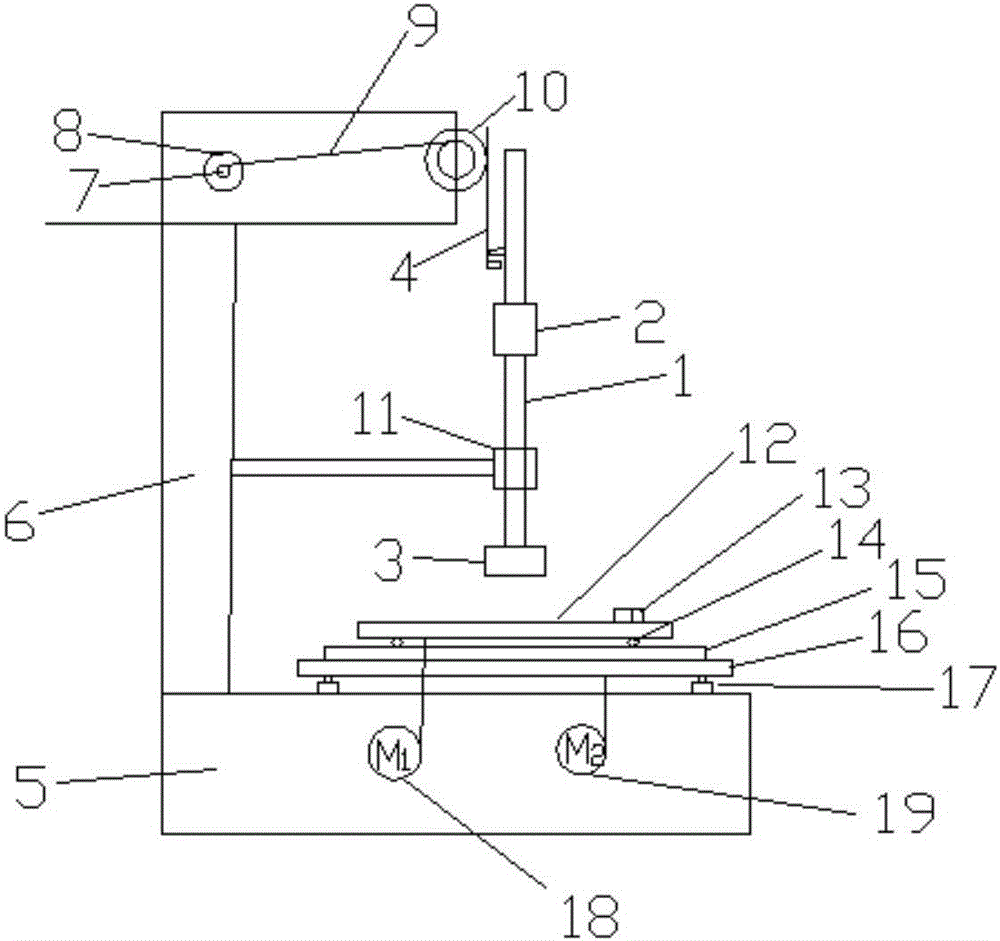

[0039] see Figure 1 to Figure 8 As shown, the present invention includes a compaction device 34 , a heating and temperature control device 35 , a base 5 , a support 6 , a trial mold fixing frame and a control panel 36 .

[0040] The trial mold fixing frame can move back and forth, left and right on the base 5, including the first motor 18, the second motor 19, the fixed slot wall 13, the movable slot wall 30, the first base plate 12, the first slide rail 15, the second base plate 16 and the second slide rail 17, etc.;

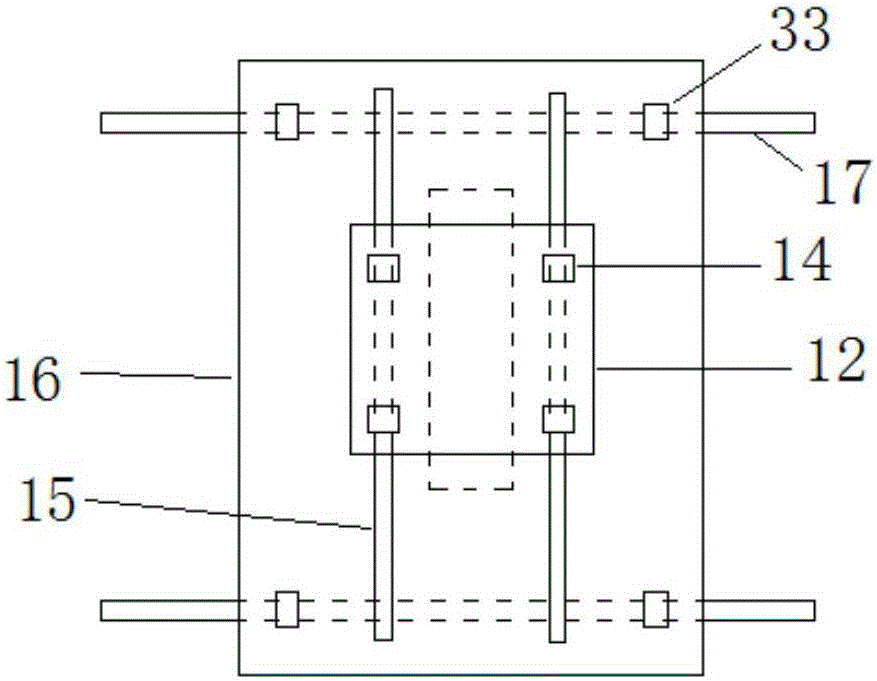

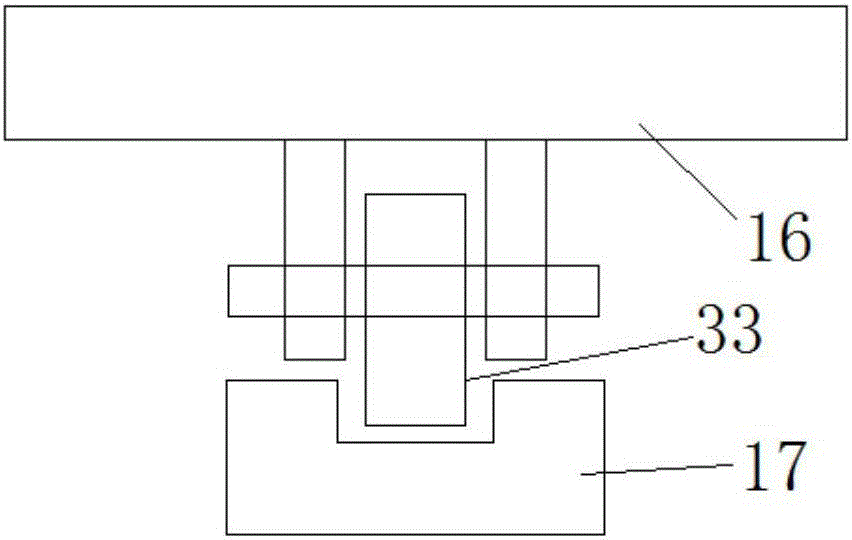

[0041] see figure 2 and image 3 , the lower surface of the first base plate 12 is equipped with a first pulley 14 , the upper surface of the second base plate 16 has a first slide rail 15 , and the first pulley 14 cooperates with the first slide rail 15 . The second bottom plate 16 lower surface has a second pulley 33, and the second sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com