Demoulding equipment for Hechuan sliced meat

A Hechuan meat slice and demoulding technology, which is applied in meat processing, application, slaughtering and other directions, can solve the problems of affecting food hygiene and safety, low demoulding efficiency, etc., so as to improve food safety, improve demoulding efficiency, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

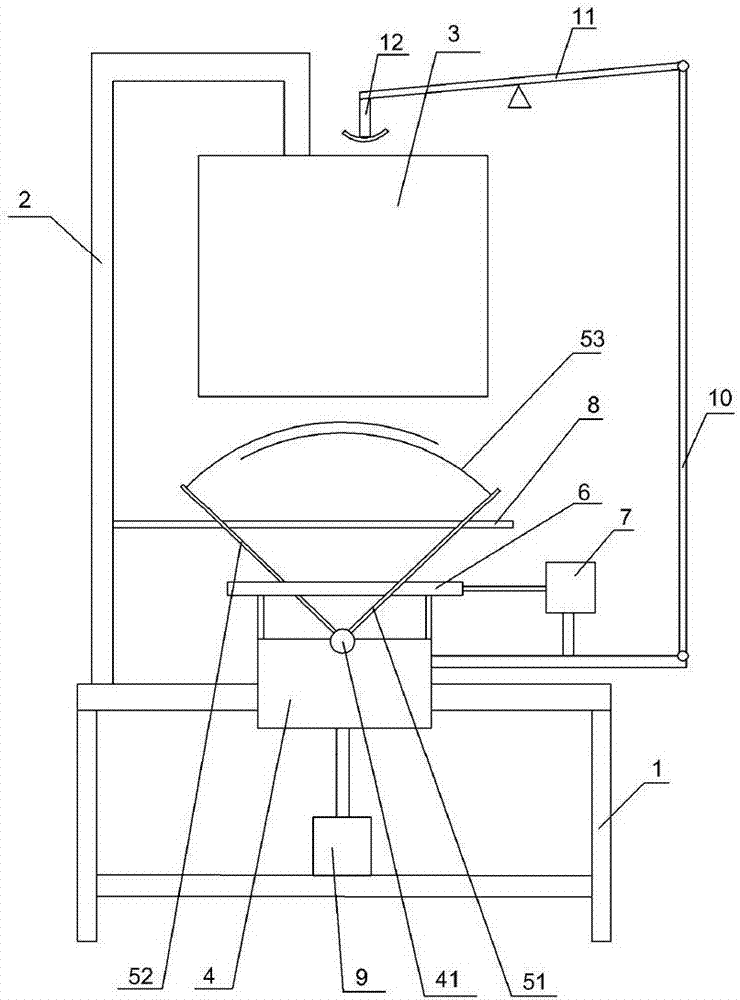

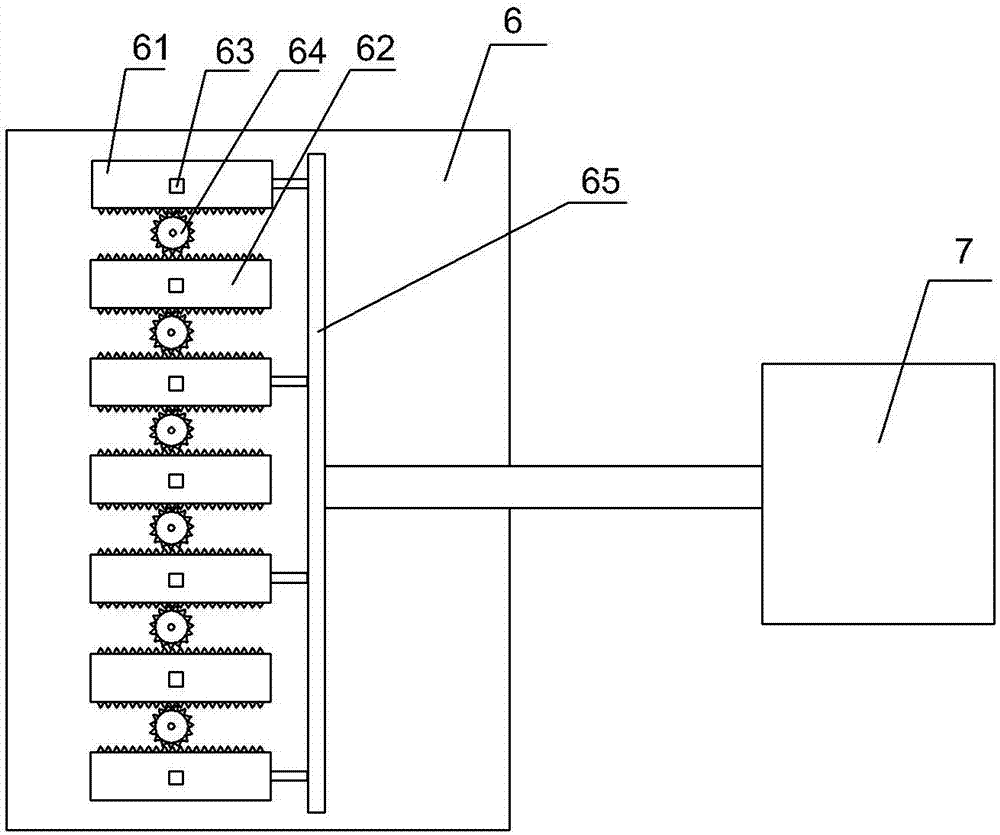

[0027] Such as figure 1 As shown, the demoulding equipment for processing Hechuan meat slices in this embodiment includes a frame 1, and the frame 1 is provided with a clamping mechanism, a stamping mechanism and an actuator.

[0028] The clamping mechanism includes a clamping part 2 for clamping the mold 3, and the clamping part 2 adopts a claw type.

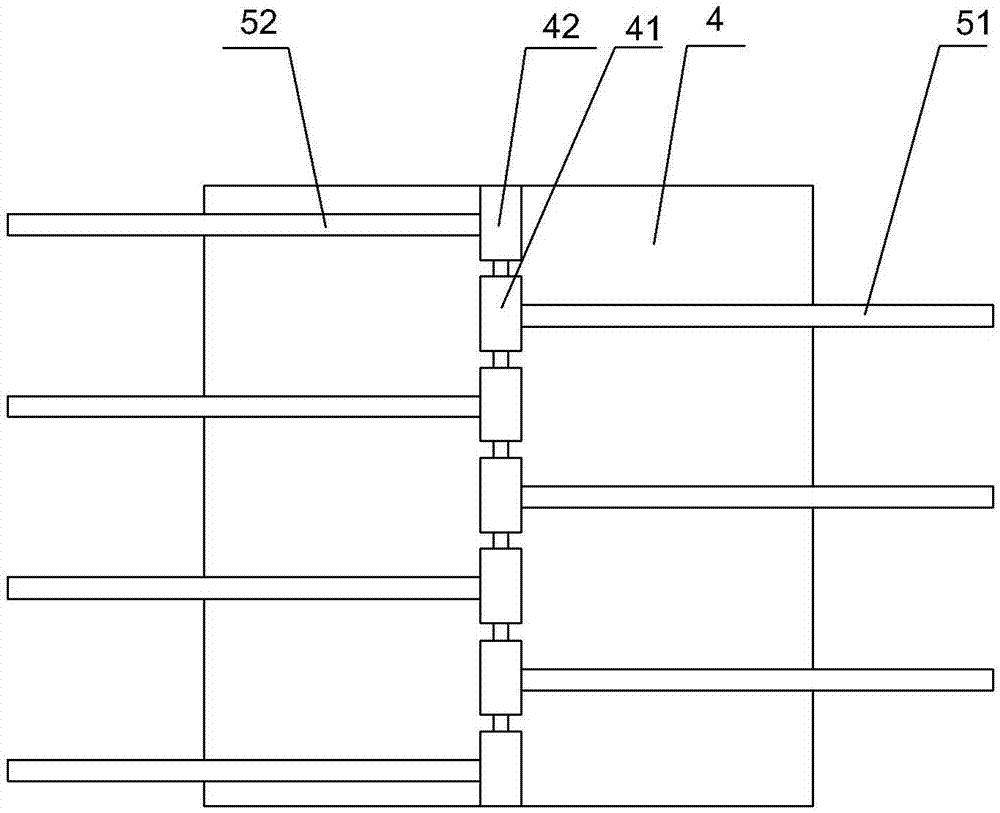

[0029] The actuator includes a mounting base 4, which can slide freely vertically on the frame 1. A cylinder 9 is installed on the frame 1 to drive the mounting base 4 to move vertically. A mandrel is welded on the mounting base 4. The mandrel extends along the length direction of the mold 3, and the mandrel is rotatably connected with three right-hand shafts 41 and four left-hand shafts 42, such as figure 2 As shown, the quantity of the left rotating shaft 42 and the right rotating shaft 41 can also be determined according to the length of the mold 3, the left rotating shaft 42 and the right rotating shaft 41 are arranged at...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the number of pressing rods 12 in this embodiment is three, and the three pressing rods 12 are evenly distributed along the width direction of the mold 3, and three pressing rods 12 are used to stamp the mold 3. The impact force received by the end face is more uniform, which avoids the situation that the meatloaf in the mold 3 only protrudes from one side of the mold 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com