Green bodies shot-blasting equipment for sinter forging

A technology of powder metallurgy and shot peening, applied in metal processing equipment, manufacturing tools, abrasive jet machine tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

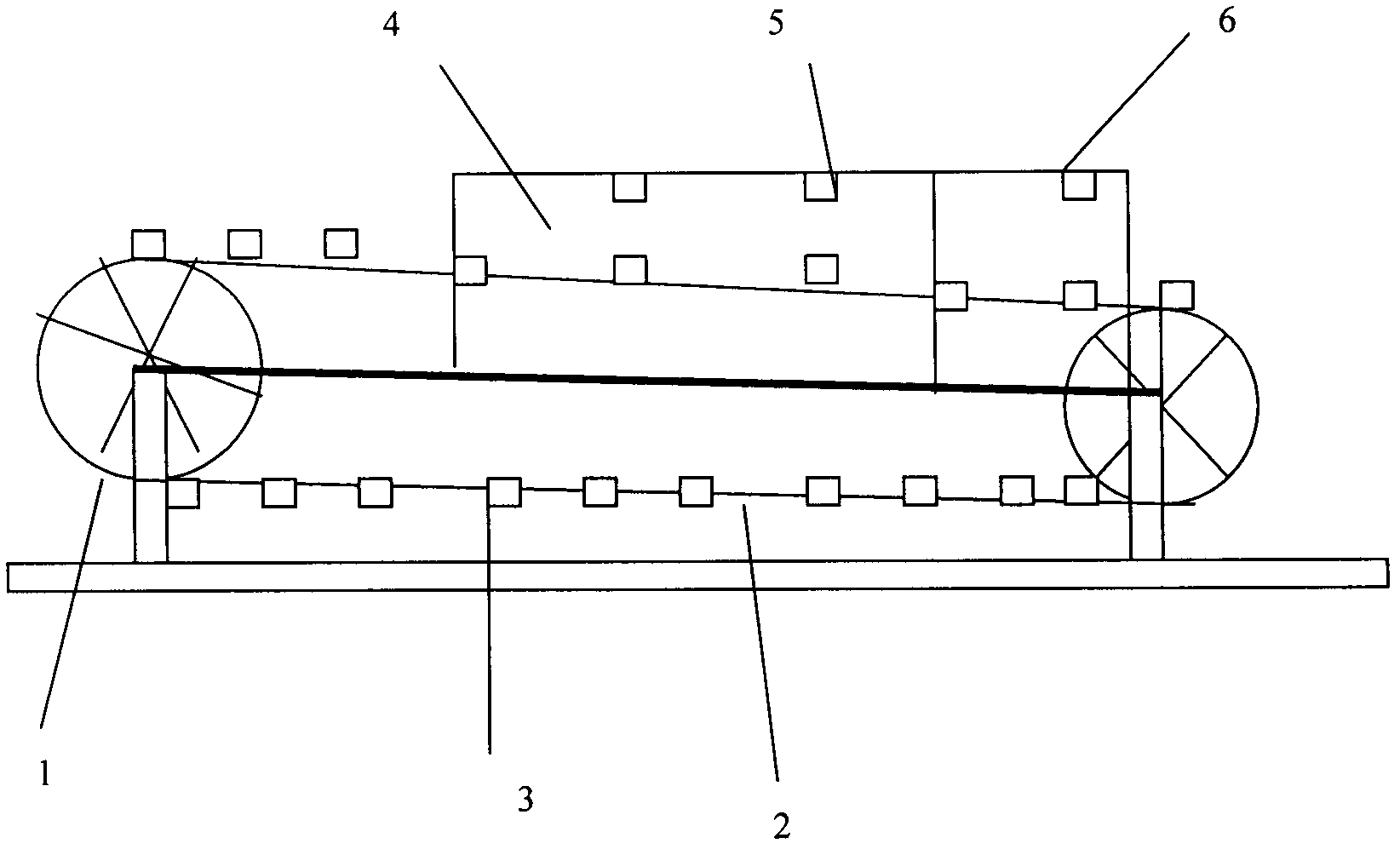

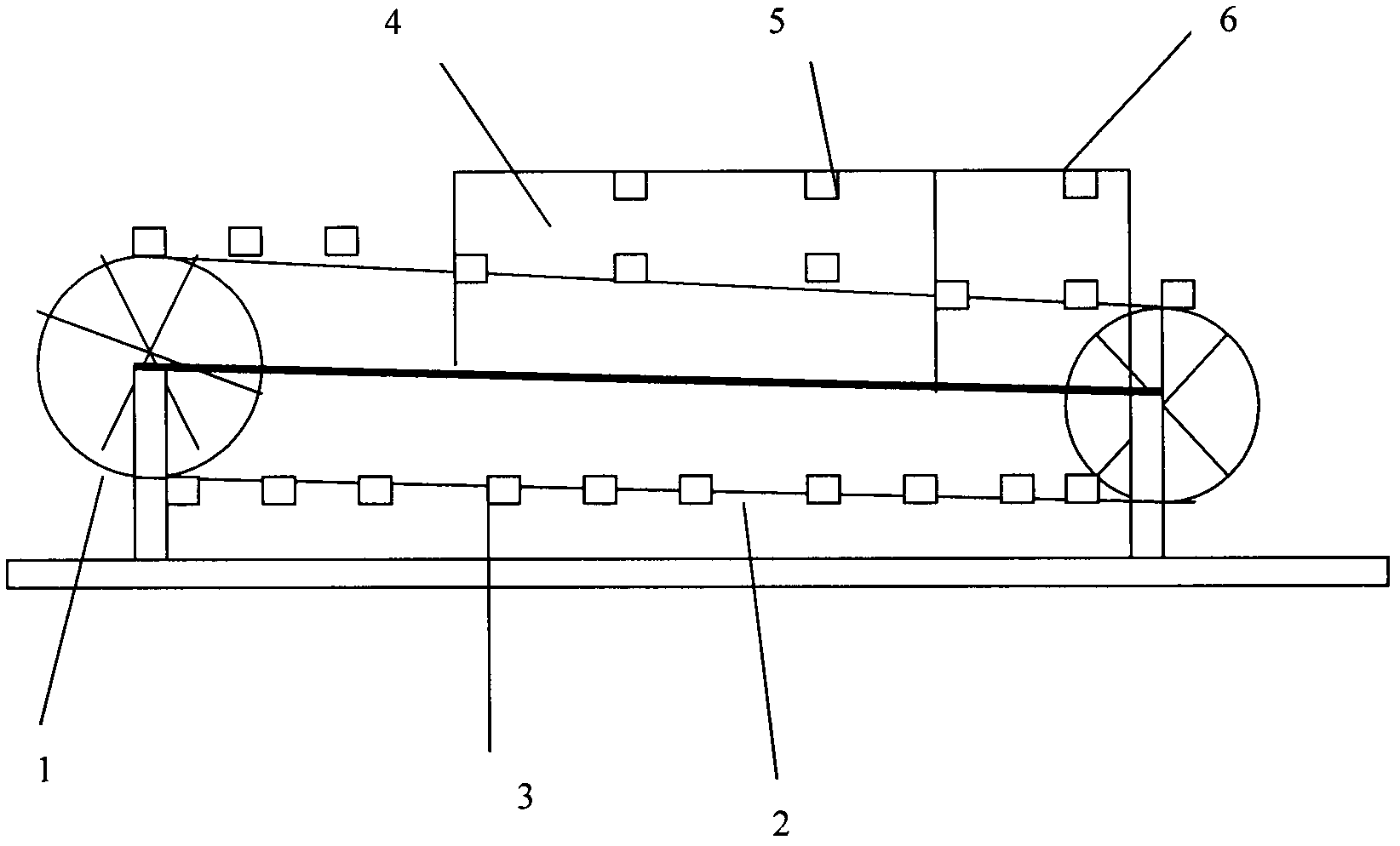

[0005] Powder metallurgy forging green body shot peening equipment, including a driving device 1, an automatic transmission mechanism, including a shot peening mechanism 4, the automatic transmission mechanism is crawler transmission, including a crawler conveyor belt 2, and a movable and rotating clamping tool 3 is arranged on the crawler conveyor belt 2, The clamping tool 3 is provided with a movable connecting rod. The shot blasting mechanism 4 includes a shot blasting chamber. After passing through the shot blasting chamber, a cleaning chamber is provided at the position where the cleaning chamber is fixed above the corresponding position of the connecting rod.

[0006] The use process is:

[0007] A. Choose the right product chuck

[0008] B. The operator embeds the connecting rod into the collet

[0009] C. The product moves forward together with the tooling, and the product will rotate after entering the shot blasting chamber

[0010] D. Multiple nozzles spray and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com