Rice processing device

A processing device and rice technology, applied in the application, magnetic separation, solid separation and other directions, can solve the problems of poor impurity removal effect, etc., and achieve the effect of improving impurity removal effect and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

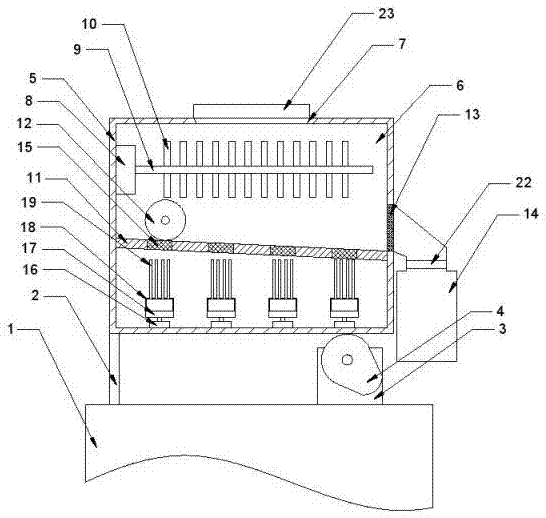

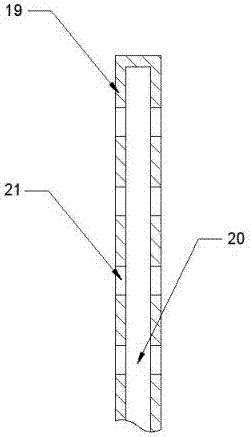

[0018] The reference signs in the drawings of the description include: machine base 1, bracket 2, drive motor 3, cam 4, box body 5, processing chamber 6, feed port 7, rotating motor 8, circular shaft 9, magnet rod 10, tilting Plate 11, gear 12, screen cloth 13, collection box 14, air net 15, cylinder 16, blower 17, air cover 18, anti-blocking rod 19, air chamber 20, exhaust hole 21, exhaust fan 22, sealing cover 23.

[0019] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a processing device for rice, including a machine base 1, on which a support 2 and an intermittent mechanism are sequentially arranged from left to right; the support 2 is hinged to the left end of the box body 5; the intermittent mechanism includes a drive motor 3 and a The cam 4 of the casing 5 is squeezed intermittently, the driving motor 3 is fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com