Method for preparing doped optical fiber outer cladding layer

A technology of doping optical fiber and outer cladding, which is applied in the field of preparation of doped optical fiber outer cladding, which can solve the problems of large stress, easy cracking of tapered slopes, and affecting the process, etc., to achieve improved impurity removal effect, quality assurance, and reliable fusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with each accompanying drawing, the present invention is described in detail.

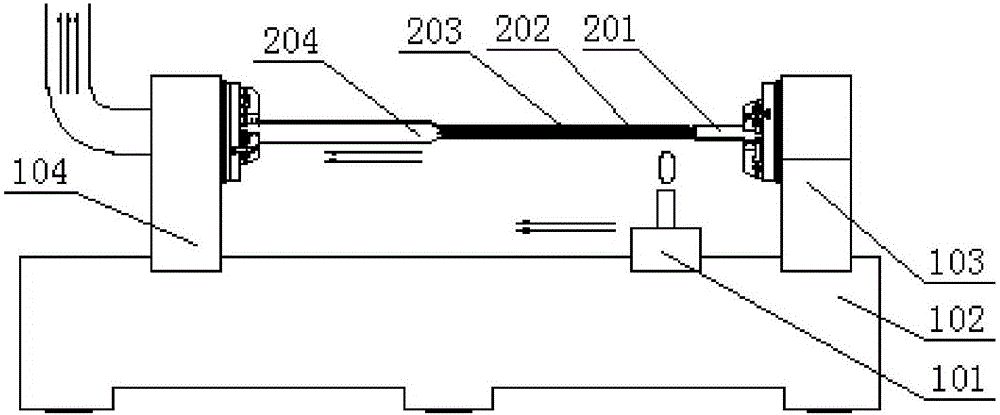

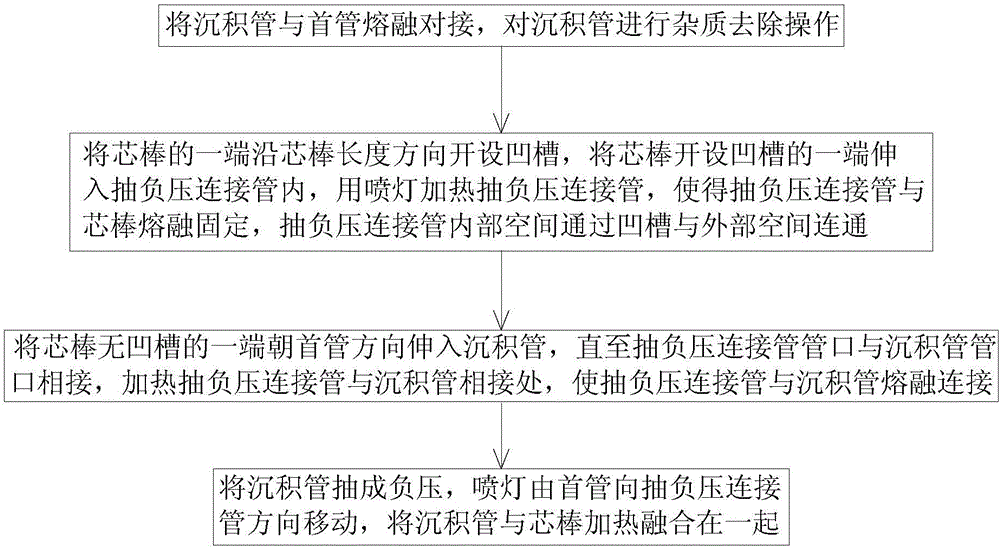

[0044] Such as figure 2 and 3 As shown, a method for preparing the outer cladding of a doped optical fiber, using MCVD equipment to fuse the deposition tube of the optical fiber preform with the core rod, includes the following steps:

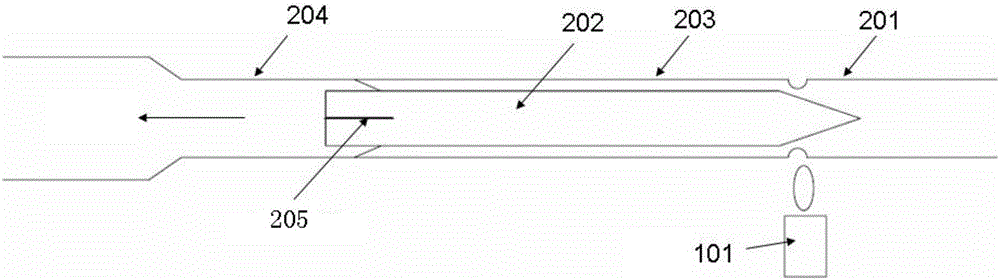

[0045] 1) The deposition pipe 203 and the head pipe 201 are fused and docked, and impurities are removed from the deposition pipe 203;

[0046] 2) One end of the mandrel 202 is provided with a groove 205 along the length direction of the mandrel, and one end of the mandrel provided with the groove is inserted into the negative pressure connecting pipe 204, and the negative pressure connecting pipe is heated with a blowtorch 101 to make the negative pressure The connecting pipe and the mandrel are melted and fixed, and the inner space of the negative pressure connecting pipe communicates with the outer space through the groove;

[0047...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com