Patents

Literature

53results about How to "Reliable fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

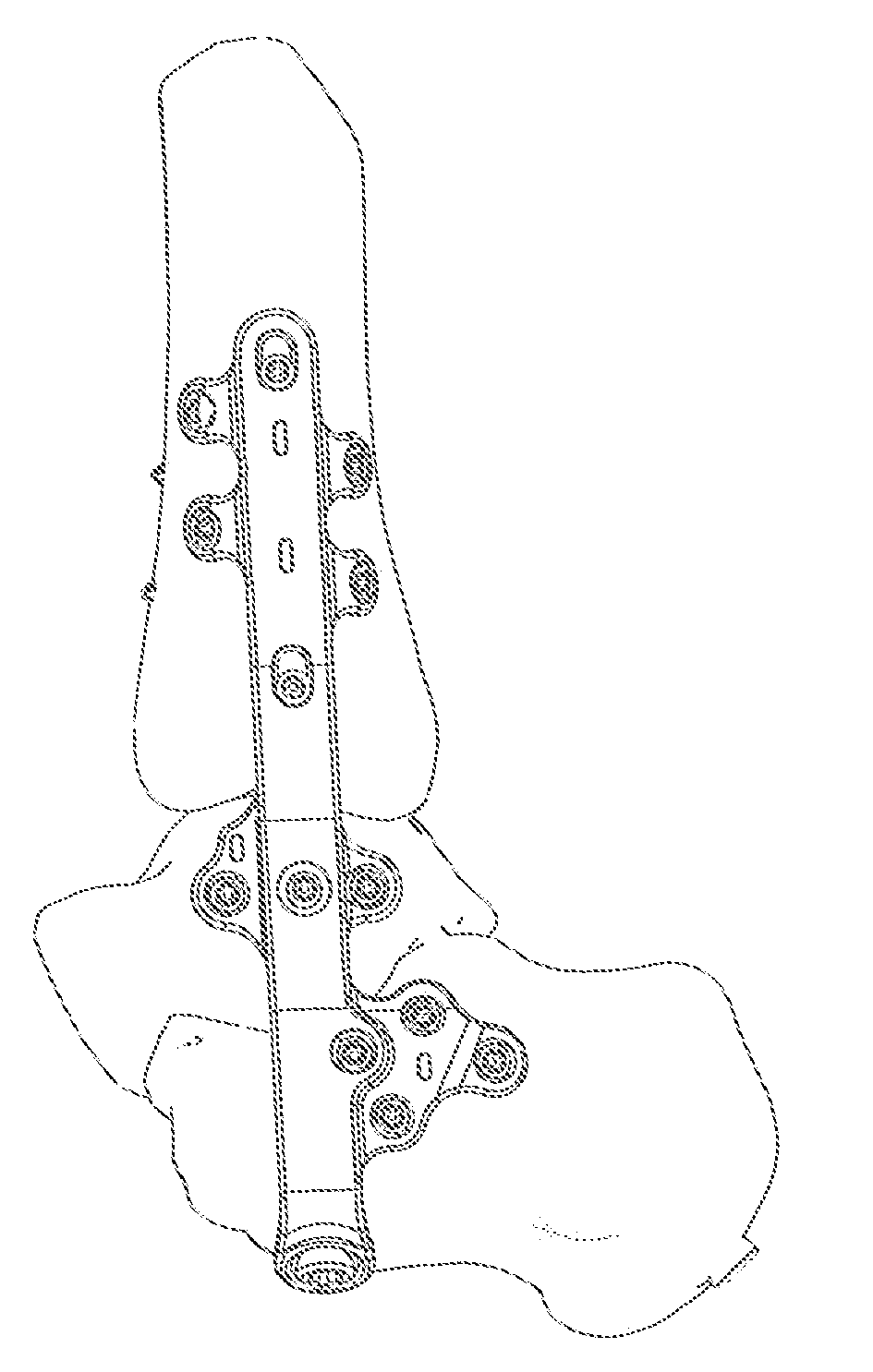

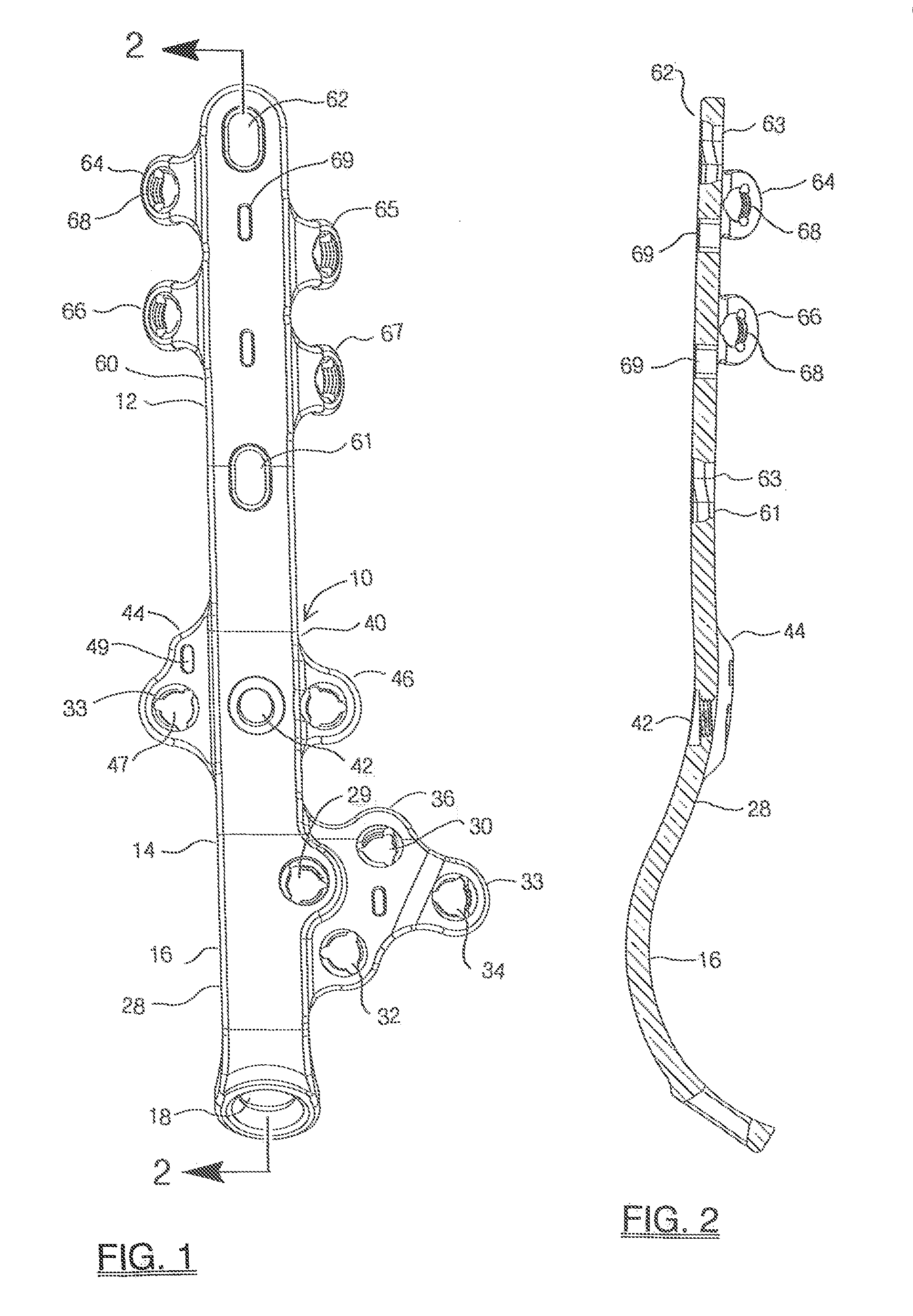

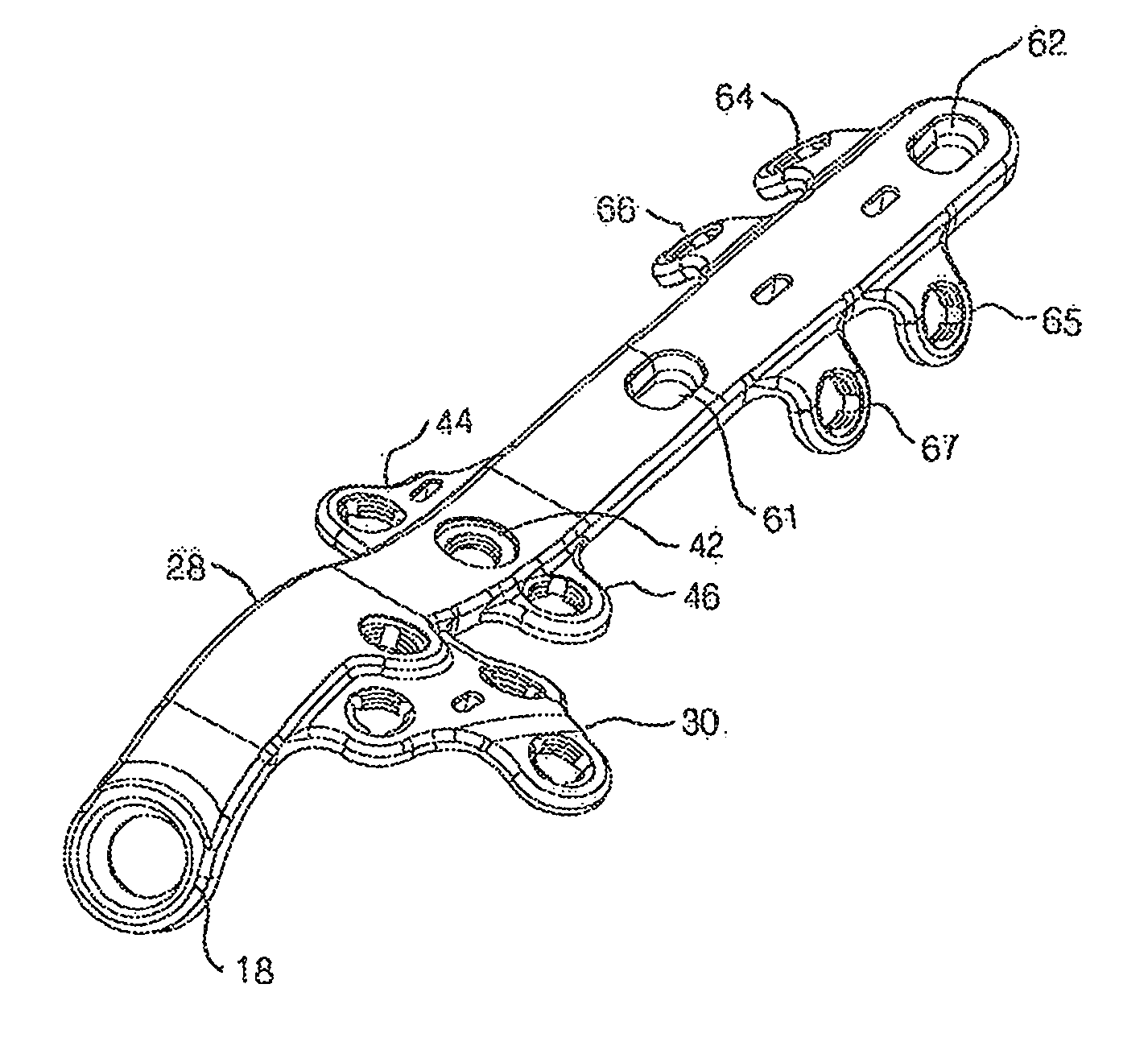

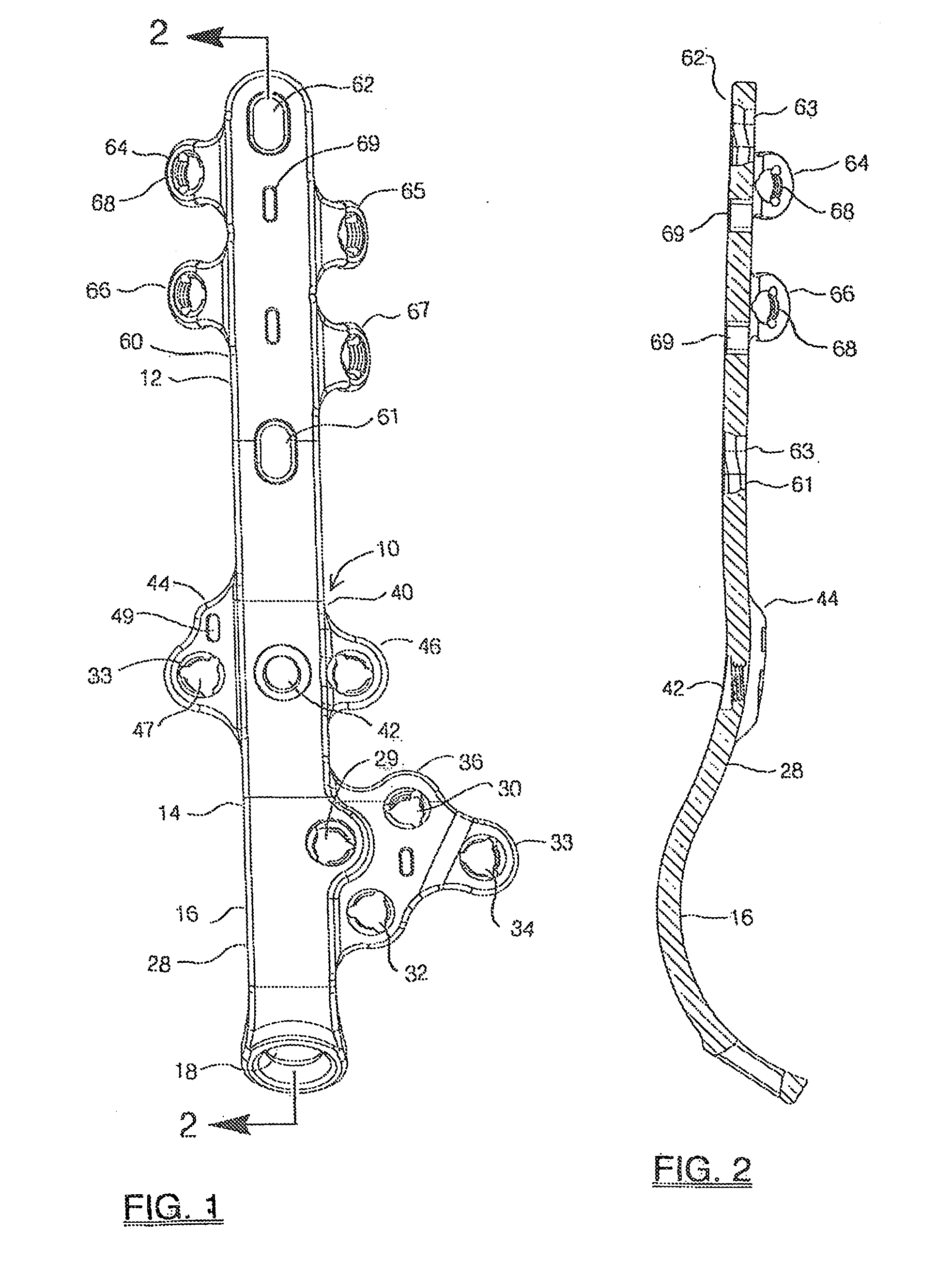

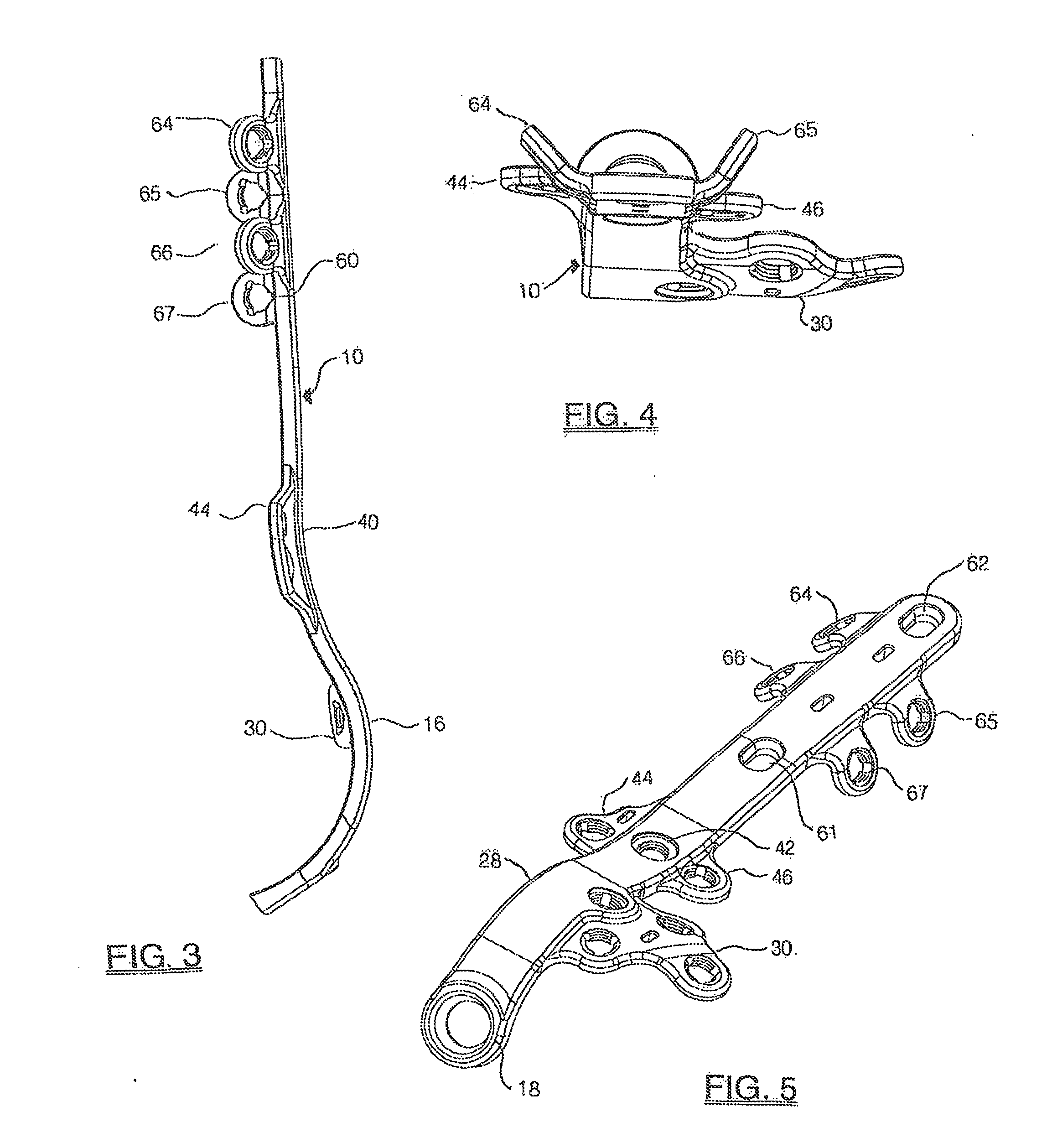

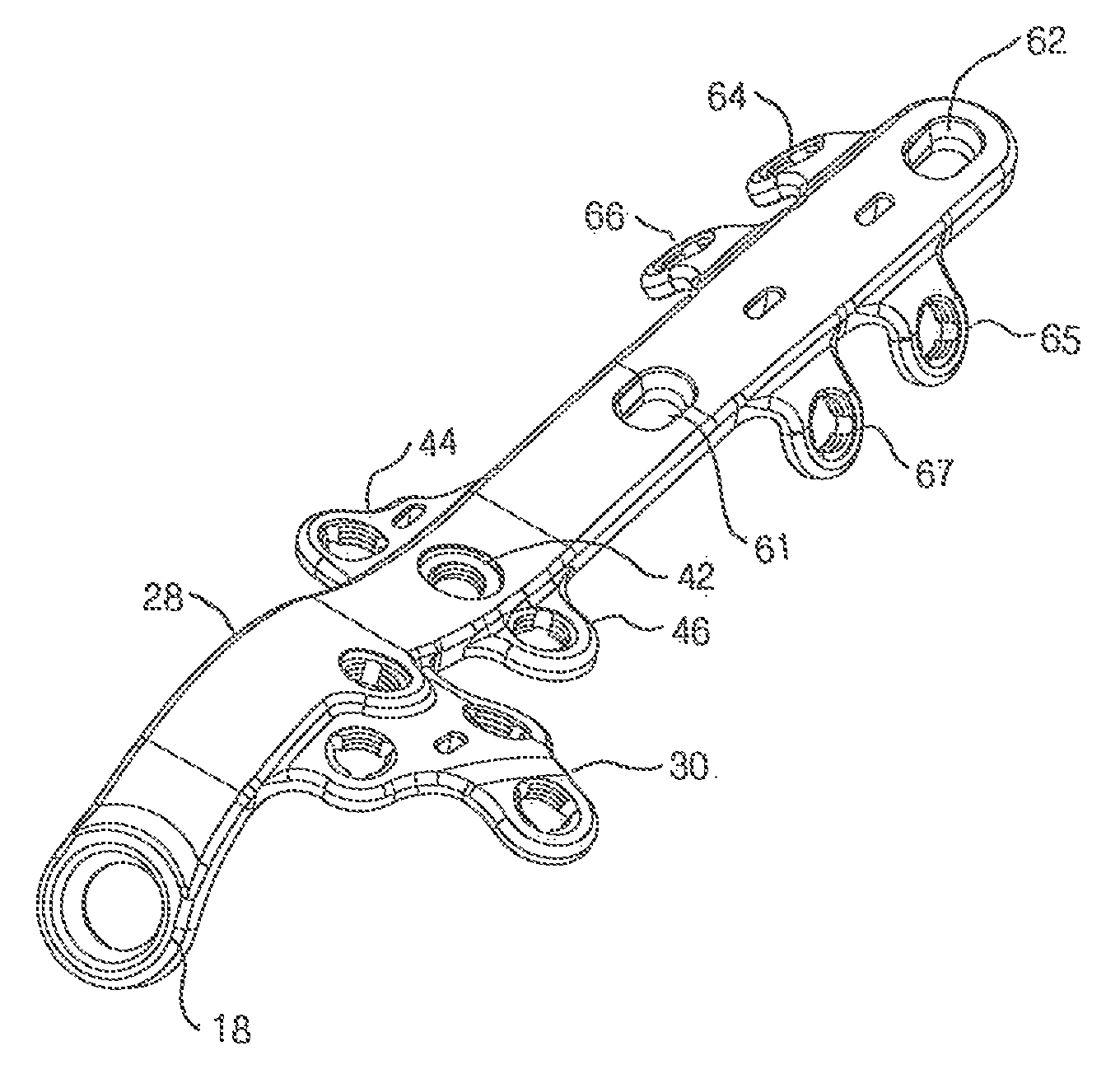

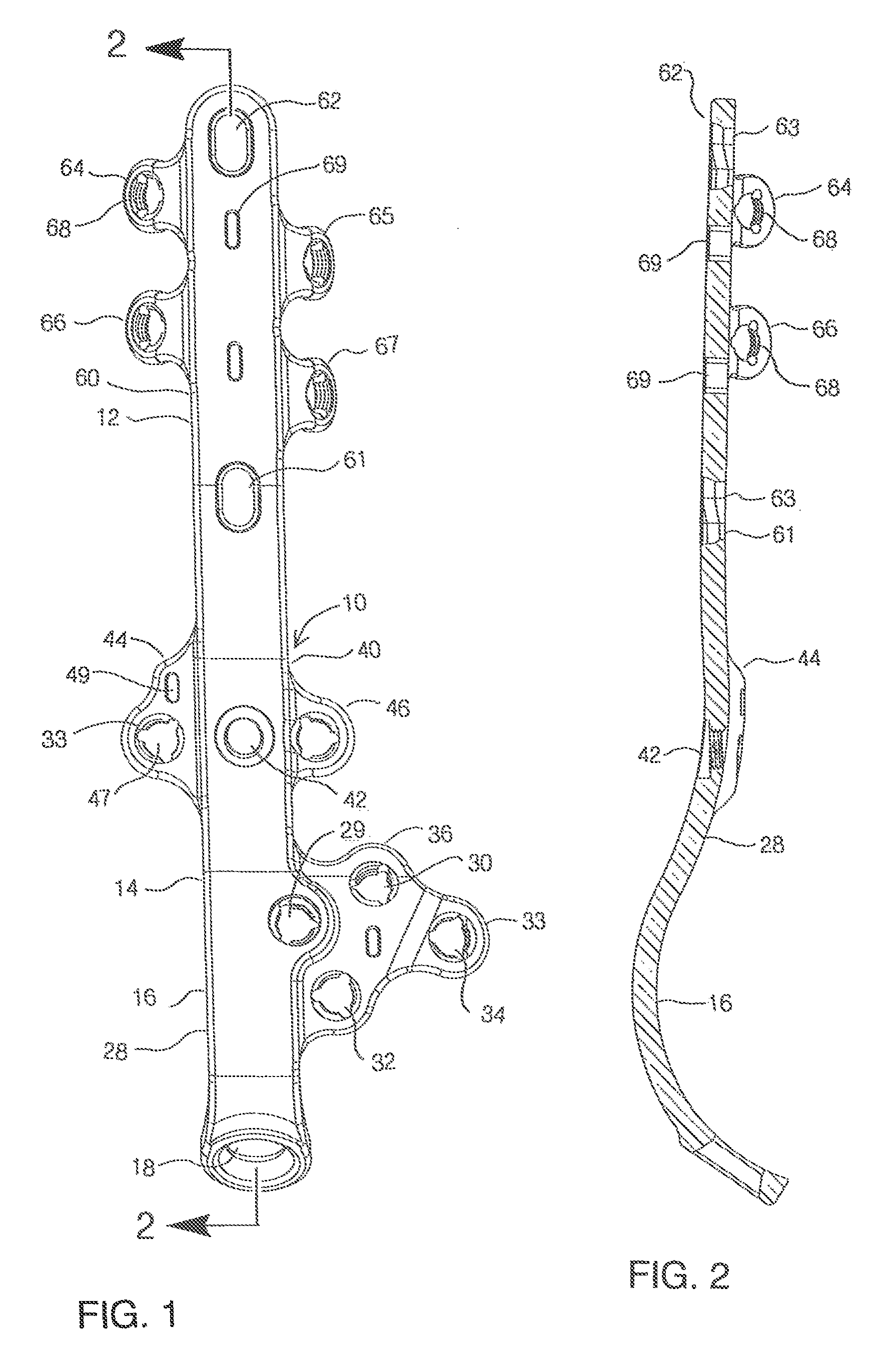

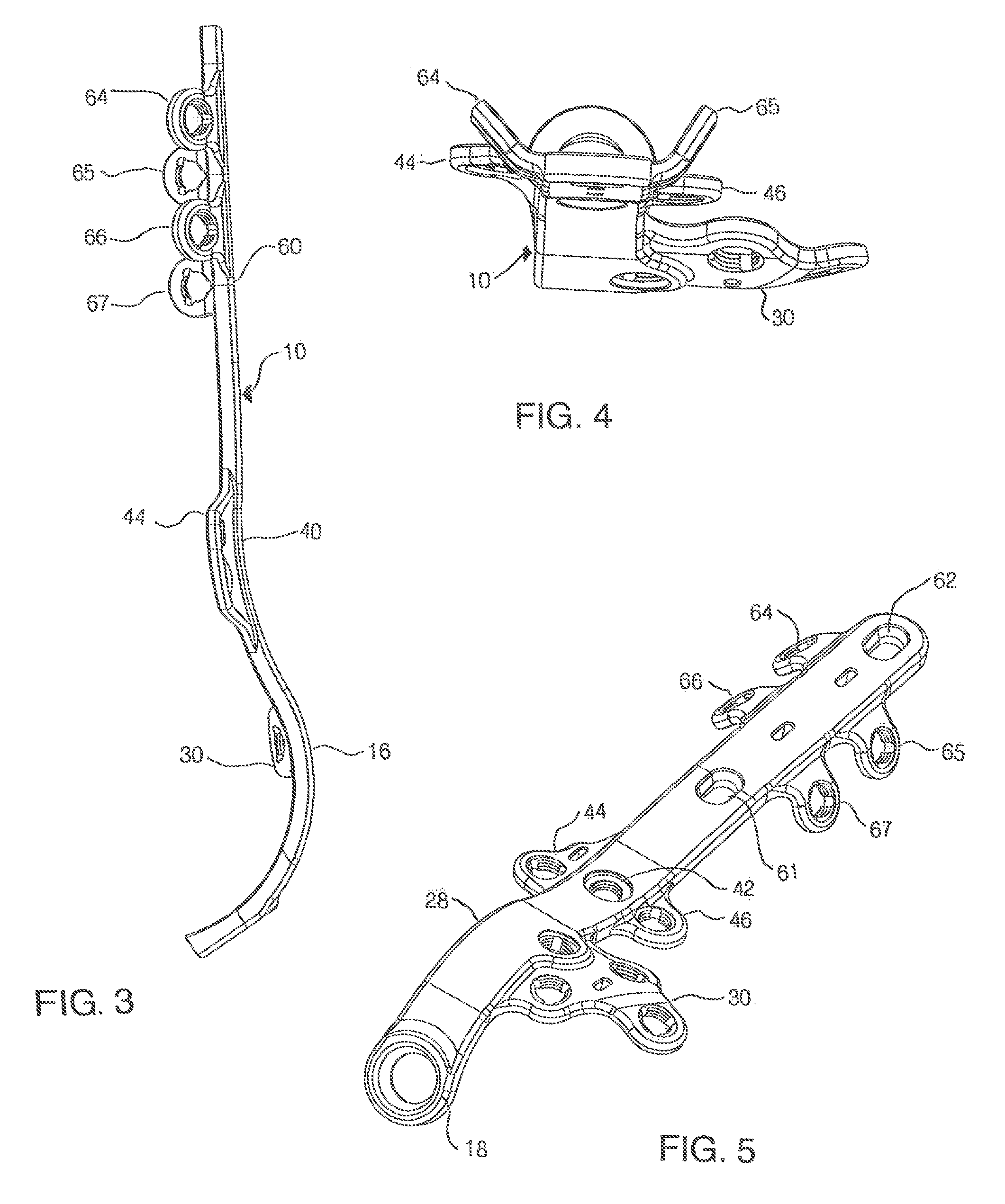

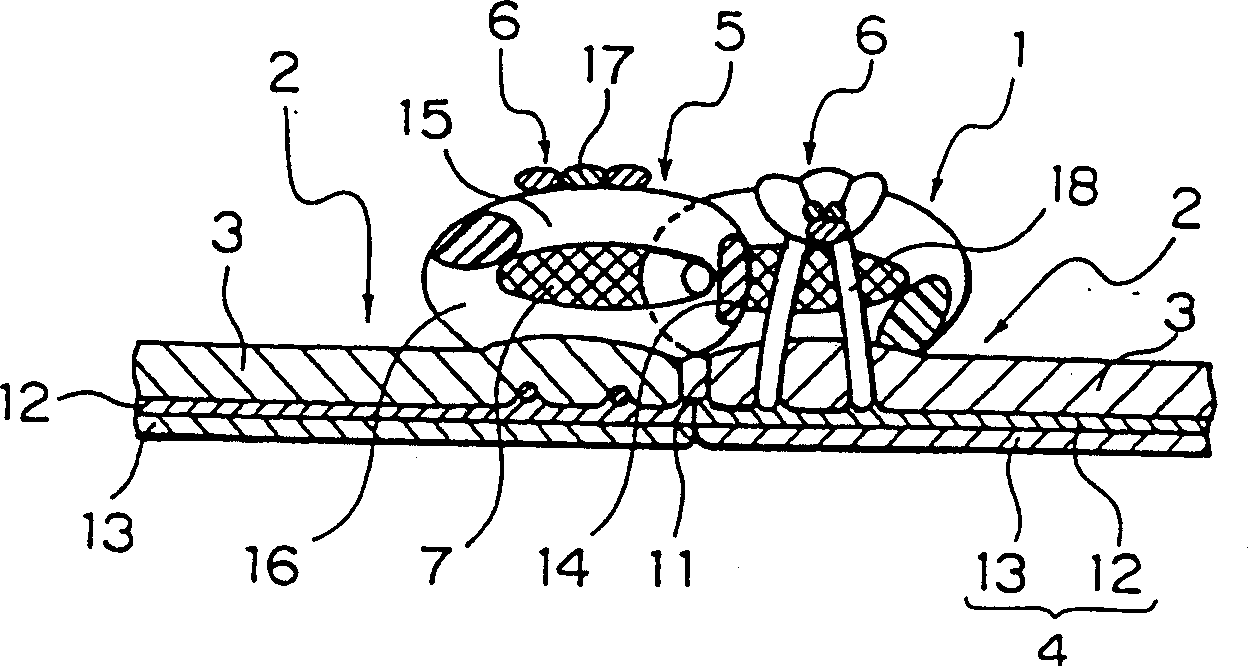

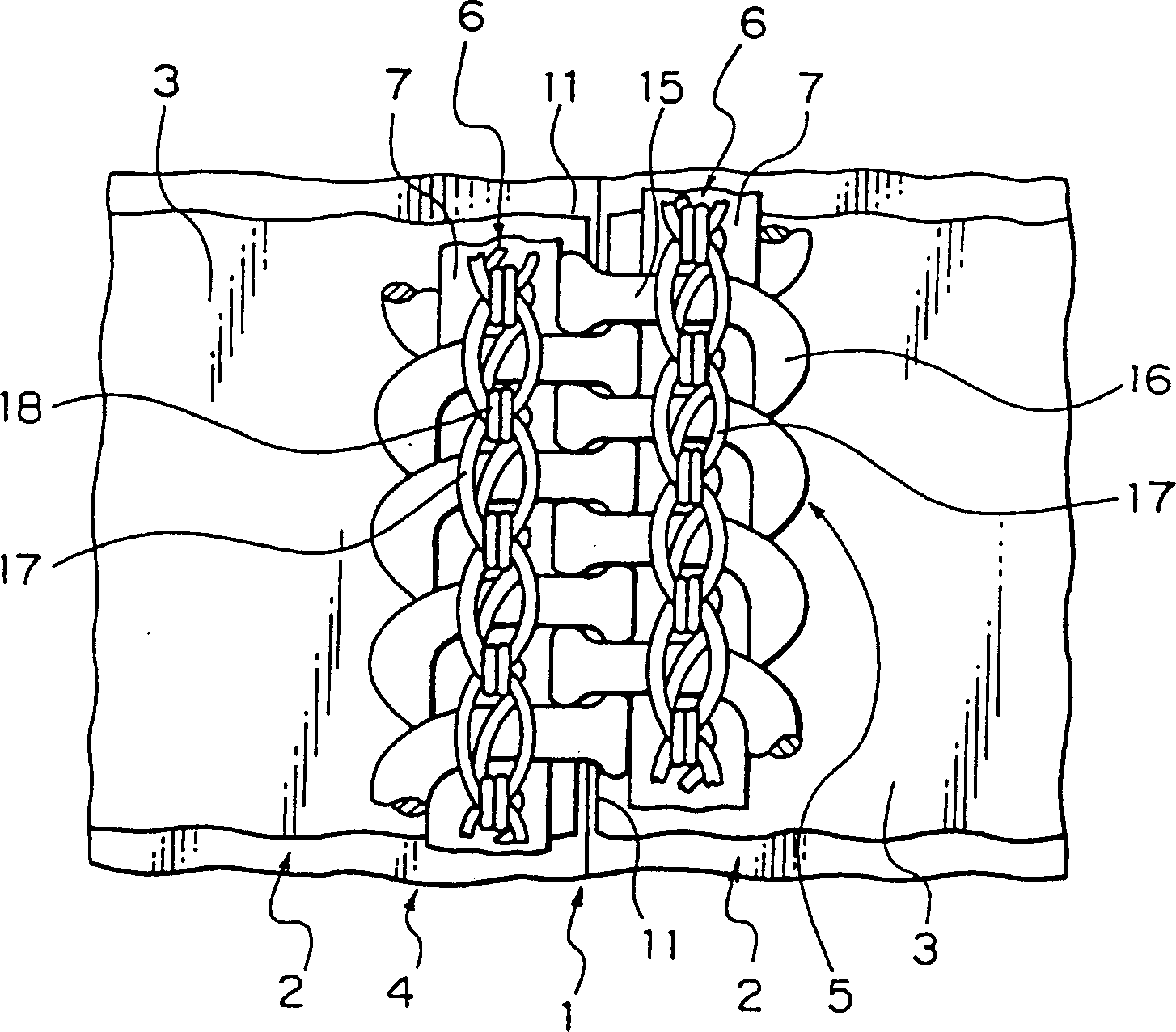

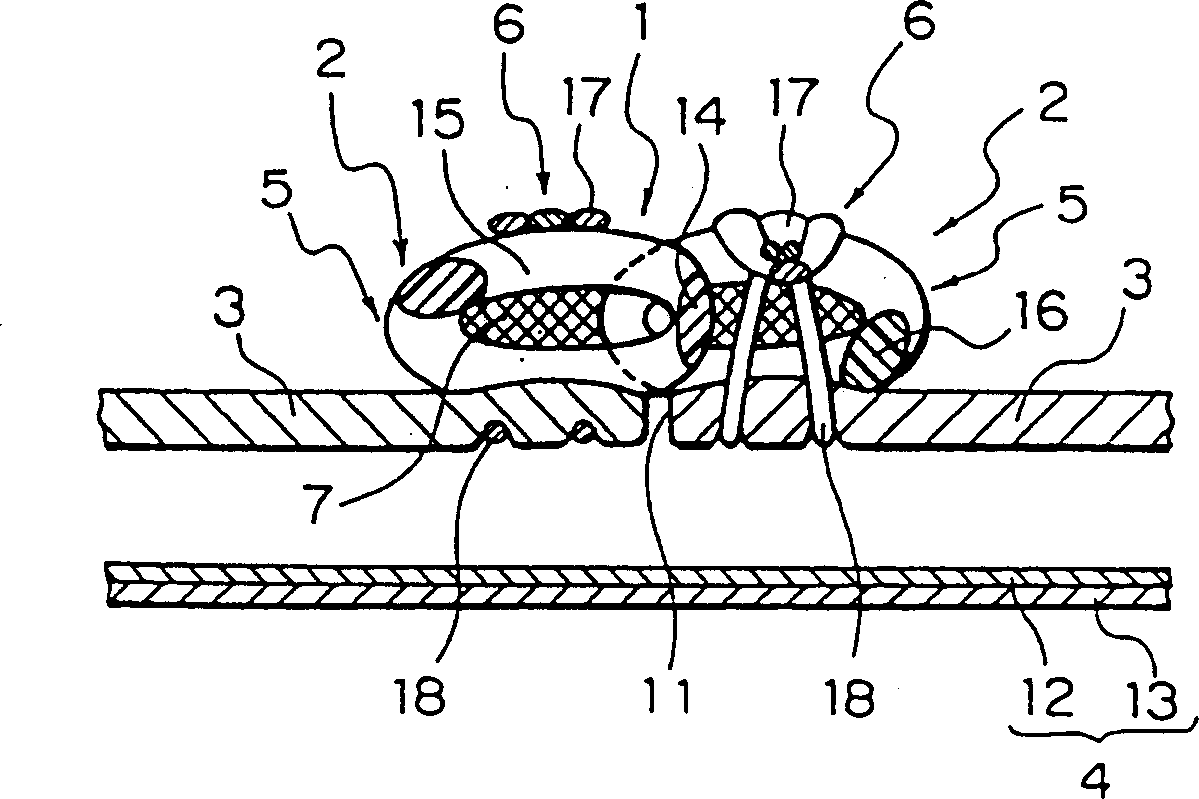

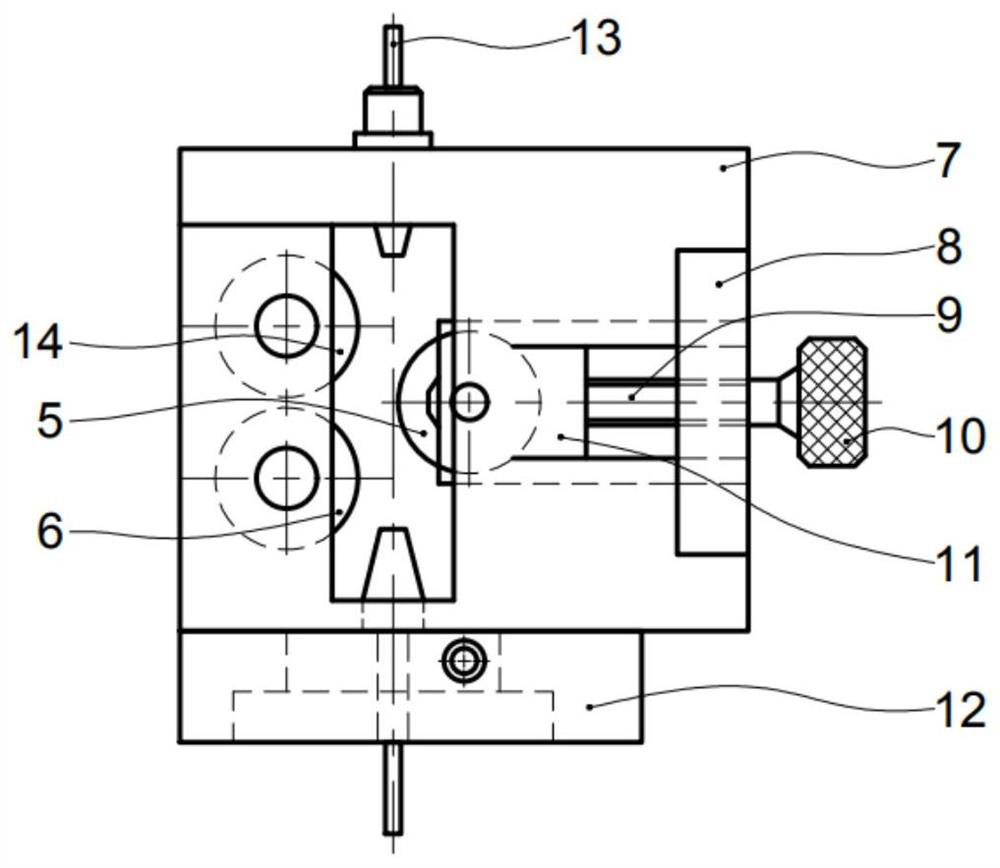

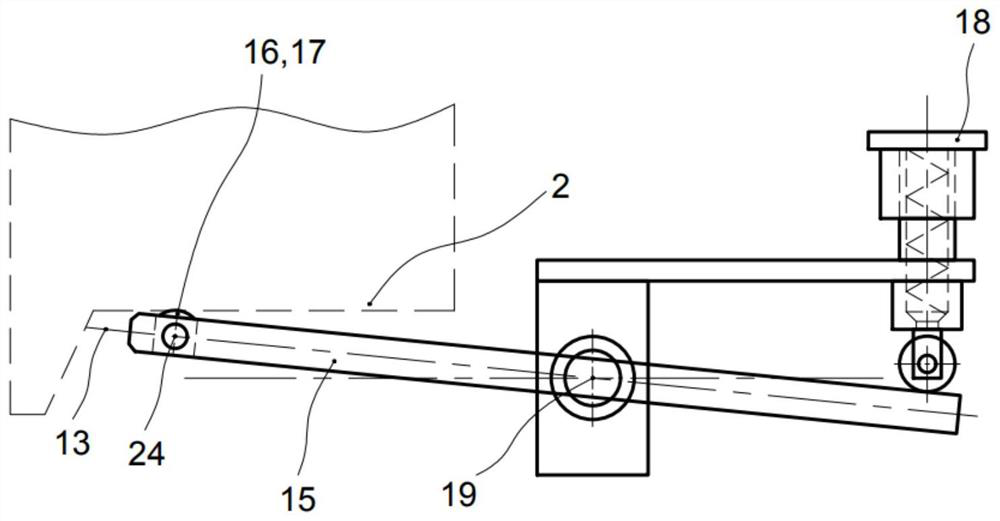

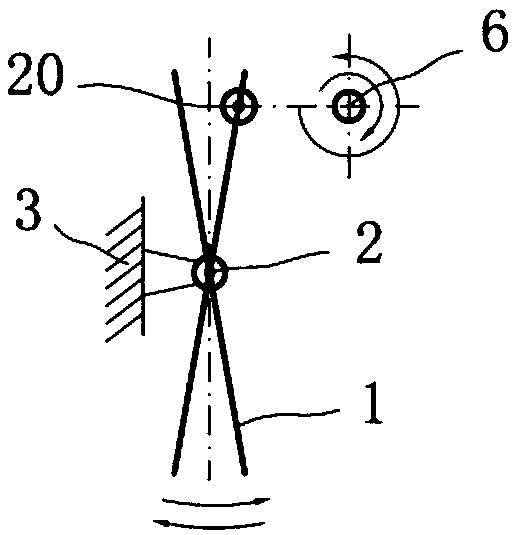

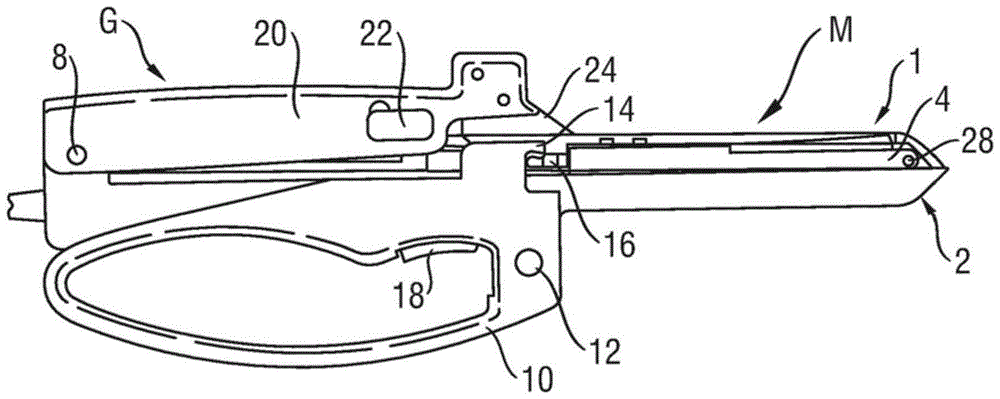

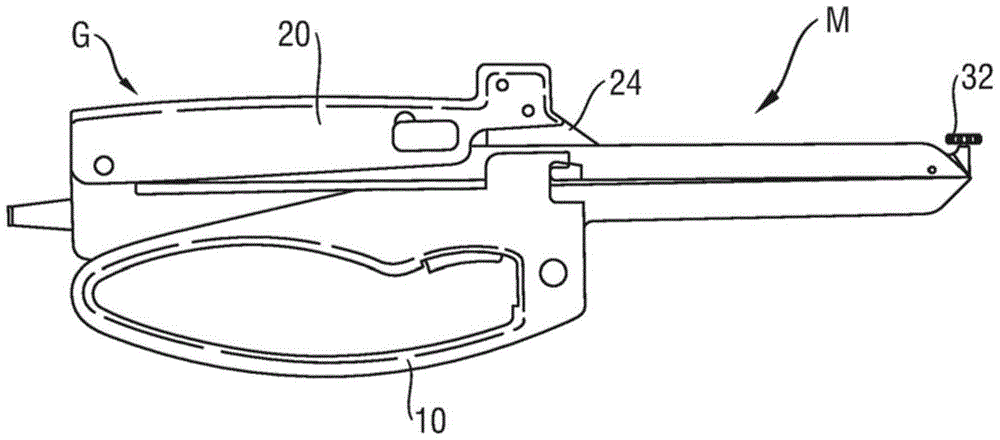

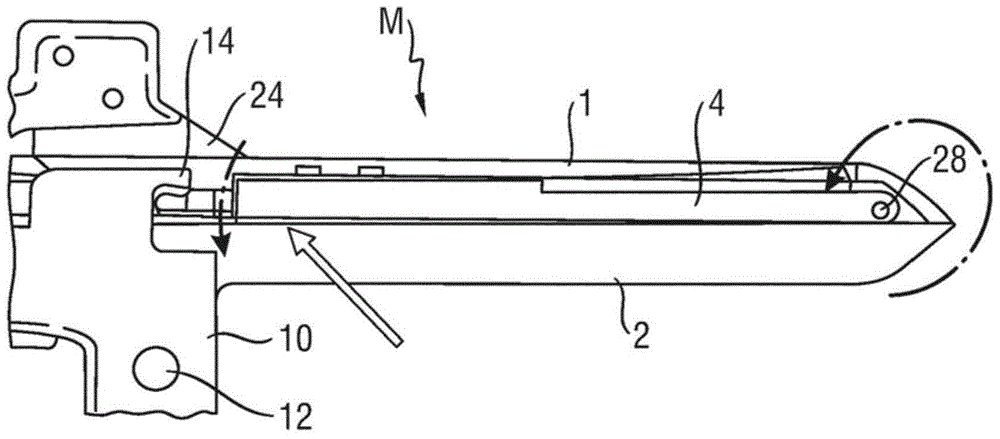

Lateral ankle fusion plate system and jig, and method for use therewith

ActiveUS20140107798A1Stable and strong and precise and comfortable for patientImprove operating conditionsAnkle jointsJoint implantsCalcaneusDistal tibia

The invention comprises a lateral ankle fusion plate, a jig for use with the fusion plate and a method for ankle fusion of the joints between the tibia, the talus, and the calcaneus. In addition, a separate fusion screw from posterior to anterior through the calcaneal tuberosity into the distal tibia is useful and can be placed using the targeting jig of the invention. The plate includes a C-shaped stirrup portion that wraps the bottom of the calcaneus and is provided with a screw hole for a T-T-C-fusion screw. A C-shaped targeting jig is provided that interfaces with the plate to allow for placement of the calcaneal screw and has an additional attachment for placement of the independent fusion screw so as to avoid impingement with the plate, and plate screws. The invention also relates to a method of surgery that incorporates the use of the plate, the jig and the tibial / talar / calcaneal fusion screw for an arthrodesis of the ankle joint.

Owner:ORTHOHELIX SURGICAL DESIGNS

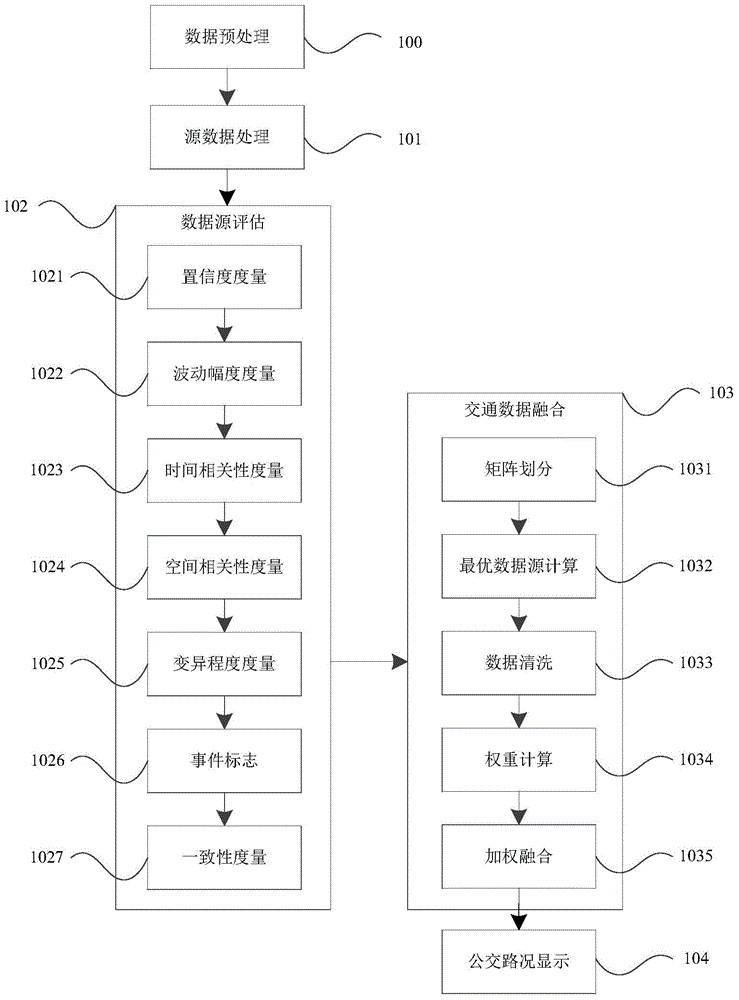

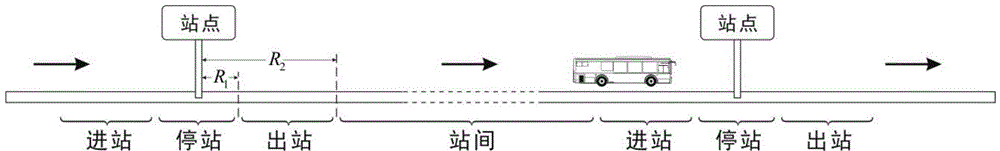

Bus road condition processing system and method based on traffic multi-source data fusion

ActiveCN104134349APrecision FusionFast fusionDetection of traffic movementEvaluation resultRoad networks

The invention discloses a bus road condition processing system and method based on traffic multi-source data fusion. The bus road condition processing system comprises a preprocessing module, a source data processing module, a data source evaluation module and a data fusion module. The preprocessing module is used for processing traffic multi-source data; the source data processing module is used for processing data of a non-bus data source road condition calculation result; the data source evaluation module comprises an evaluation framework used for evaluating the quality of data sources, and the credibility of multi-source data to the bus road condition calculation result can be obtained through processing of the evaluation framework; the data fusion module is used for performing weighted calculation on the multi-source data based on the data source evaluation result, and finally the required bus road condition data are obtained; a display module is used for superposing a bus road condition map and a map file obtained through processing and displaying road condition information of the whole bus road network. By synthesizing the multiple traffic data source road condition calculation results, the advantages of all the sides can be made the best of, the fusion result information used for describing the bus road conditions can be obtained, and data support is provided for bus service.

Owner:BEIHANG UNIV

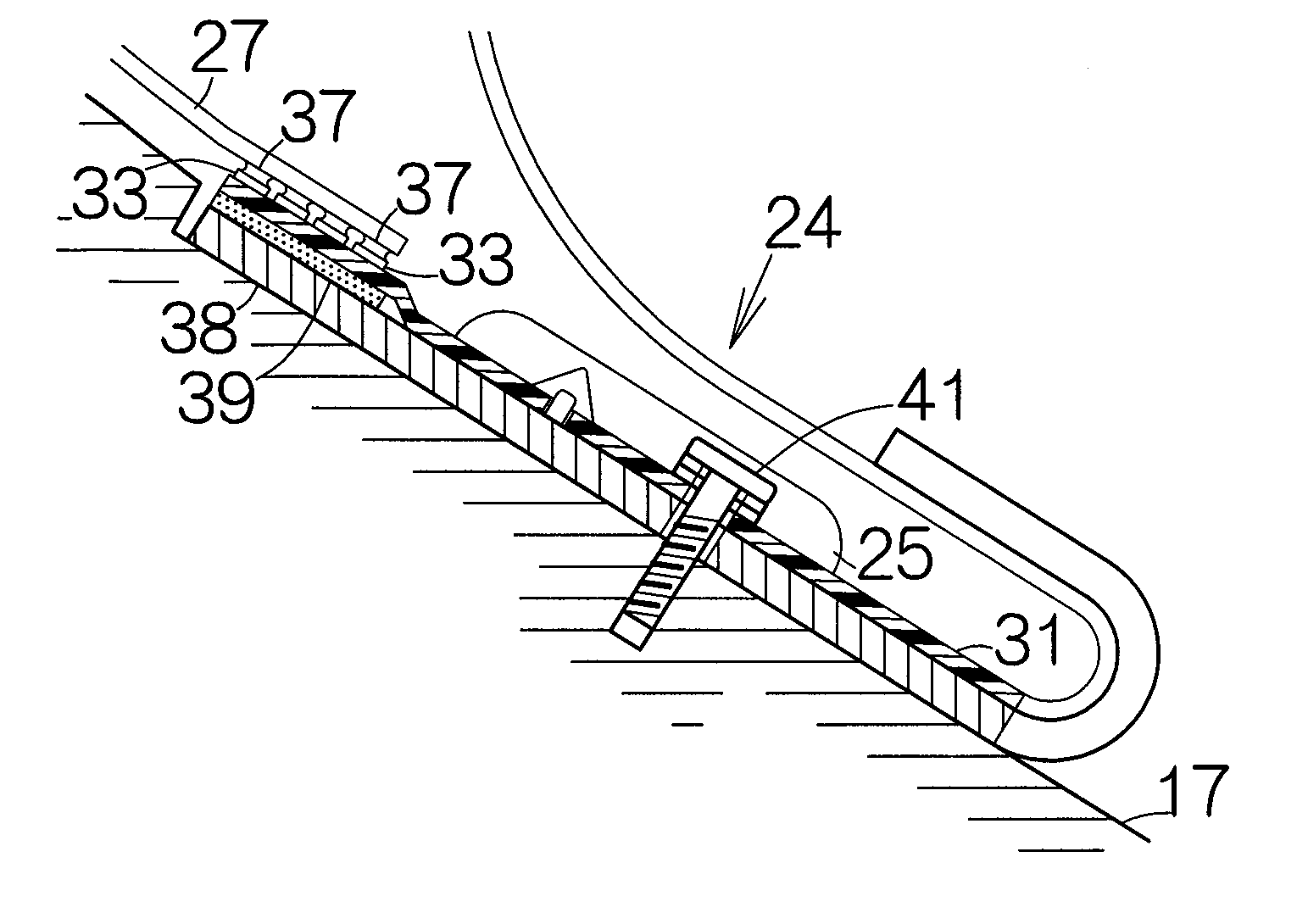

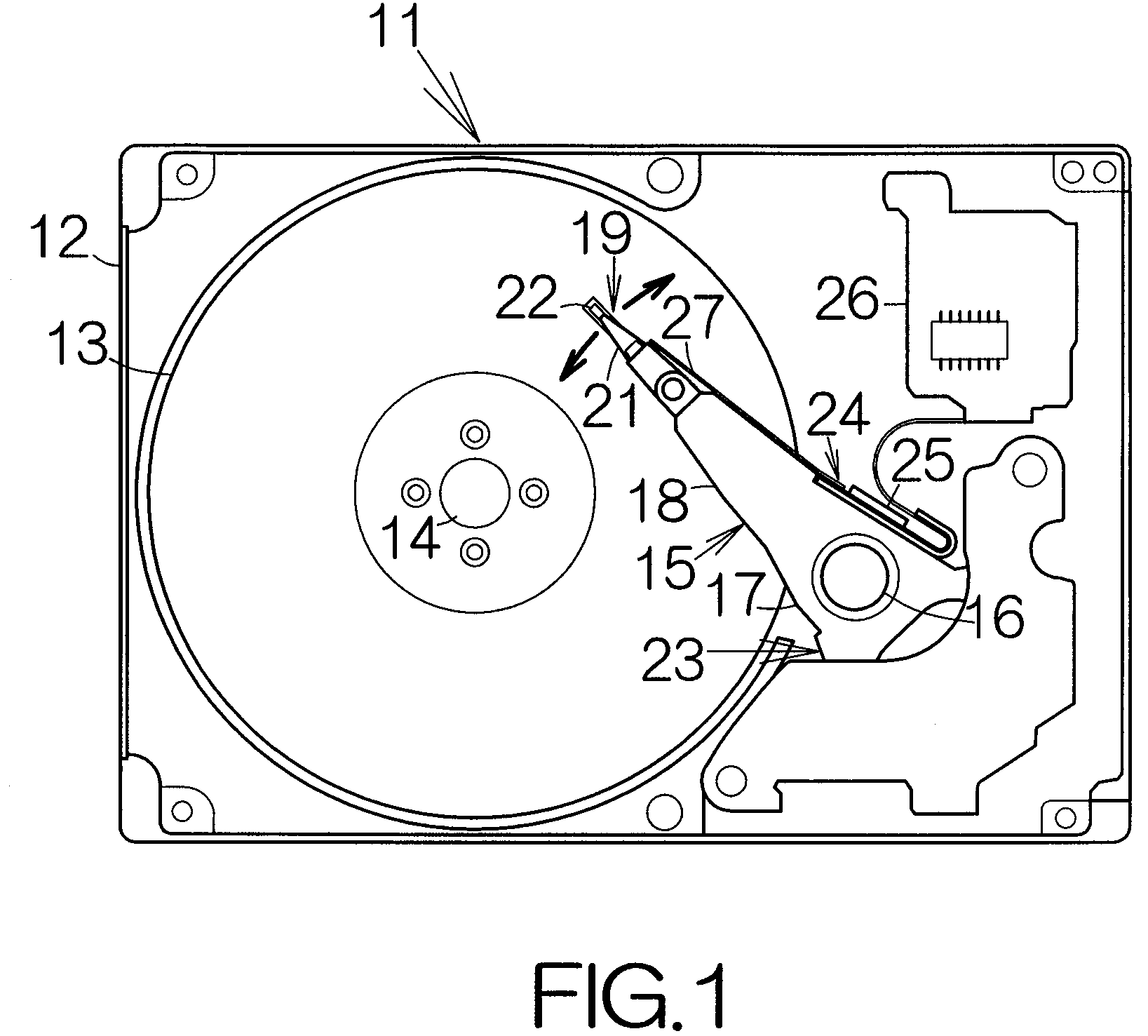

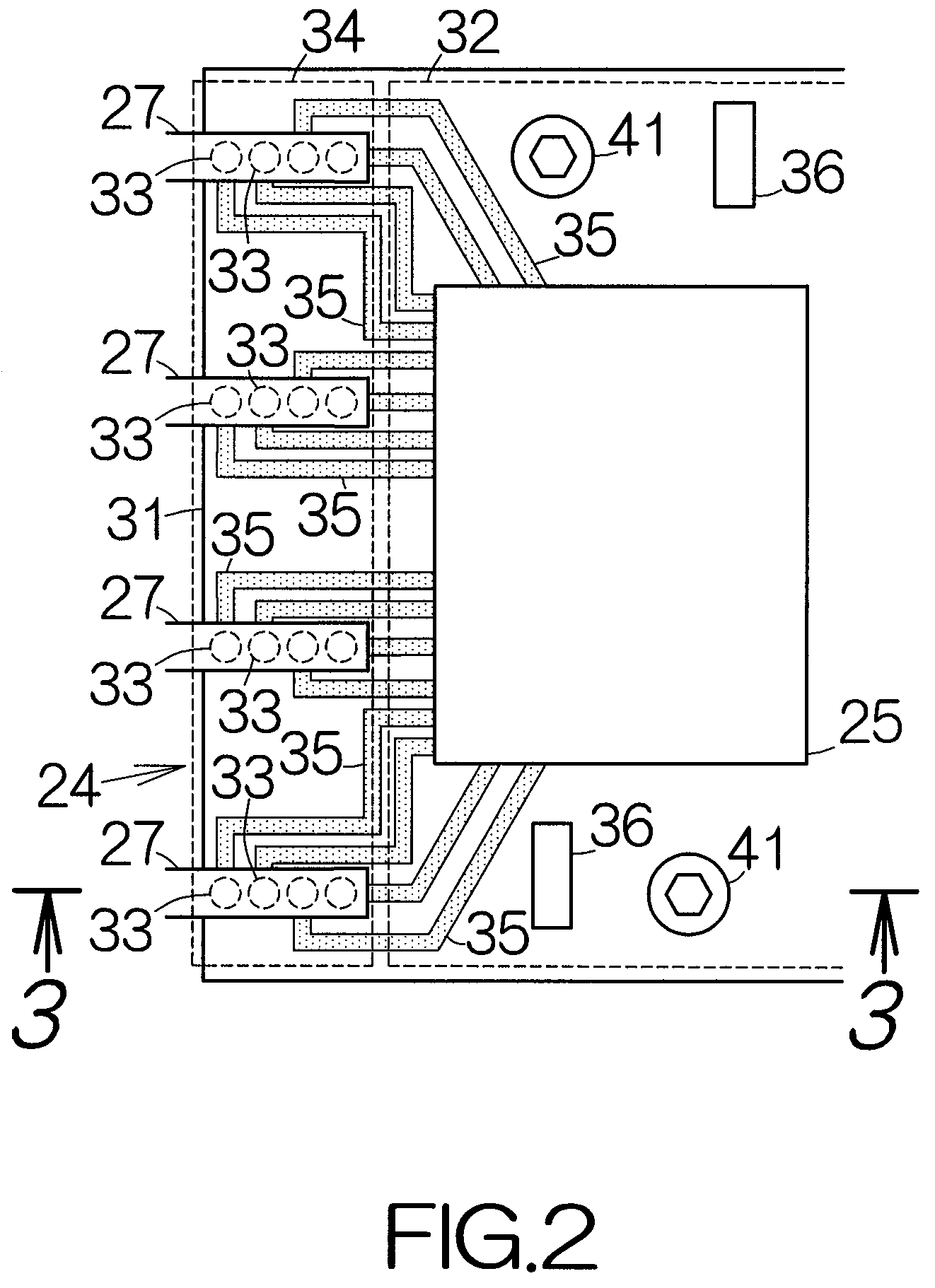

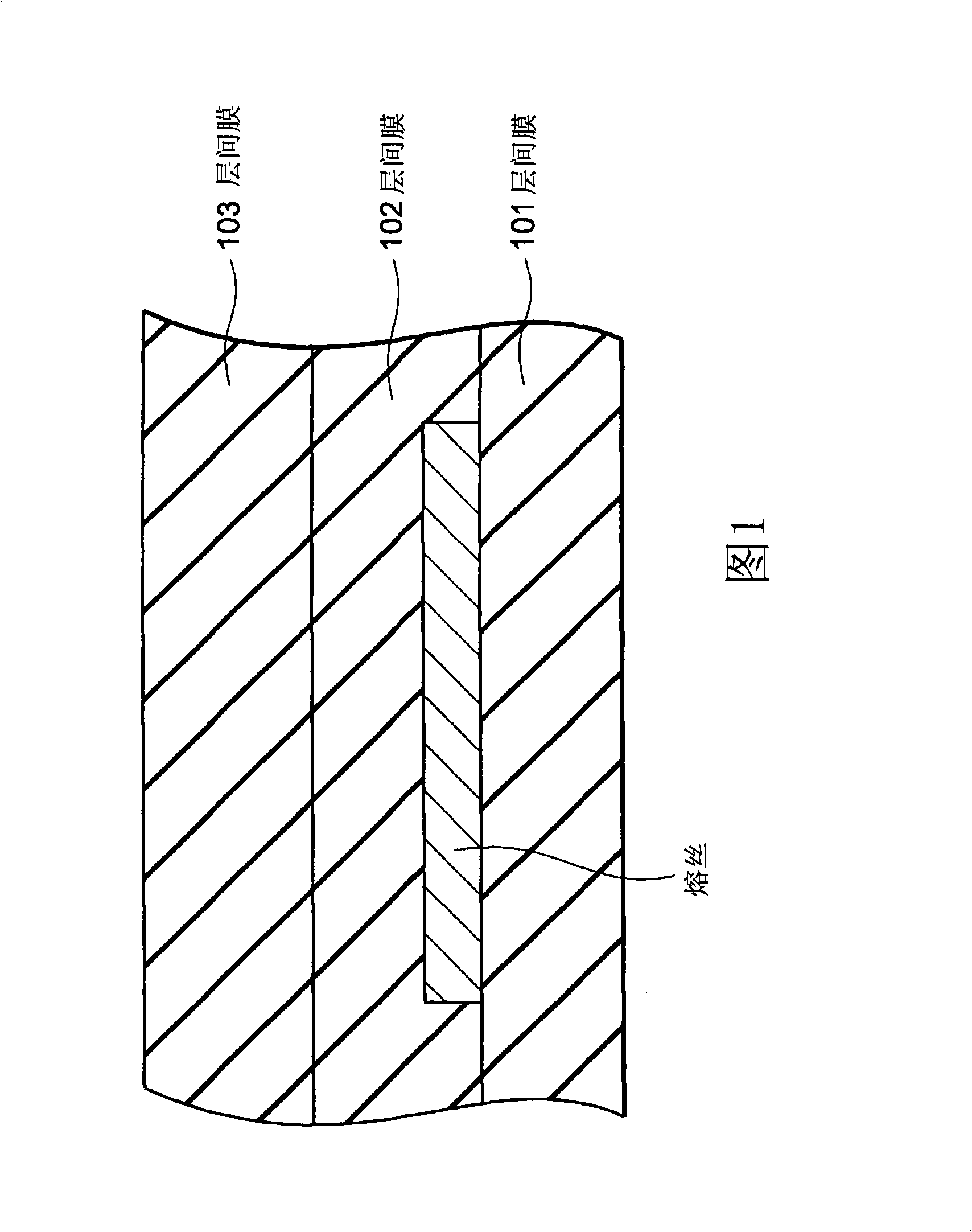

Flexible printed circuit board unit contributing to reliable soldering and suppression of increased temperature

InactiveUS6992864B2Avoid deformationUndesirable limitationElectrical connection between head and armApparatus for flat record carriersConductive materialsFlexible electronics

A thermal component is mounted on the front surface of an isolator sheet within a first specific area. A thermally-conductive material is located on the back surface of the isolator sheet on the back of the first specific area. An electrically-conductive material is located on the front surface of the isolator sheet within a second specific area. A thermally-insulating material is located on the back surface of the isolator sheet on the back of the second specific area. The flexible printed circuit board unit of this type allows heat of the thermal component to efficiently radiate from the thermally-conductive material. An increase in temperature can be suppressed in the thermal component. Heat can reliably stay in the electrically-conductive material when a solder material is applied to the surface of the electrically-conductive material. The solder material is allowed to reliably fuse.

Owner:FUJITSU LTD

Lateral ankle fusion plate system and jig, and method for use therewith

InactiveUS20160354128A1Stable and strong and precise and comfortable for patientEasy to implantAnkle jointsJoint implantsCalcaneusDistal tibia

The invention comprises a lateral ankle fusion plate, a jig for use with the fusion plate and a method for ankle fusion of the joints between the tibia, the talus, and the calcaneus. In addition, a separate fusion screw from posterior to anterior through the calcaneal tuberosity into the distal tibia is useful and can be placed using the targeting jig of the invention. The plate includes a C-shaped stirrup portion that wraps the bottom of the calcaneus and is provided with a screw hole for a T-T-C-fusion screw. A C-shaped targeting jig is provided that interfaces with the plate to allow for placement of the calcaneal screw and has an additional attachment for placement of the independent fusion screw so as to avoid impingement with the plate, and plate screws. The invention also relates to a method of surgery that incorporates the use of the plate, the jig and the tibial / talar / calcaneal fusion screw for an arthrodesis of the ankle joint.

Owner:ORTHOHELIX SURGICAL DESIGNS

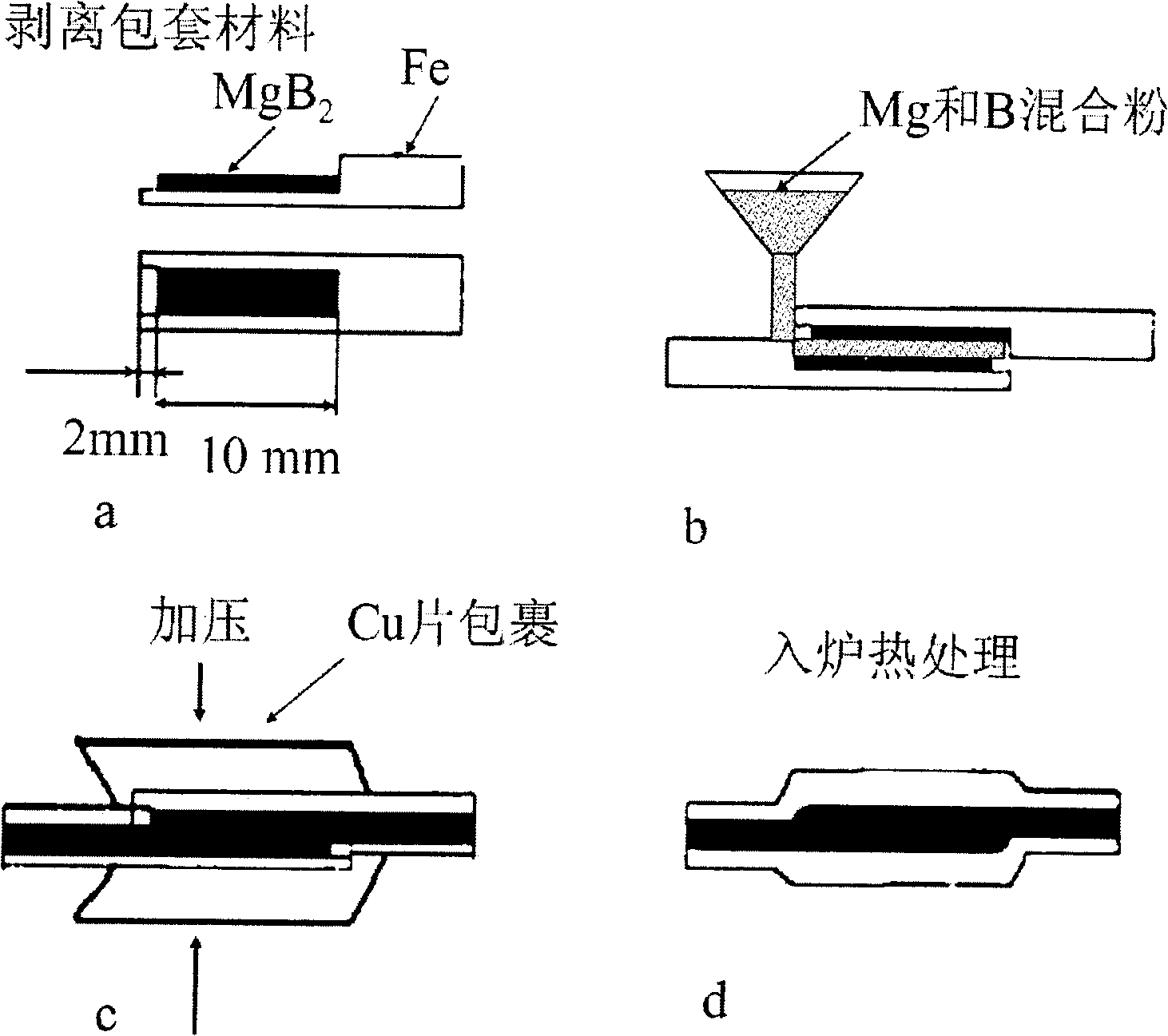

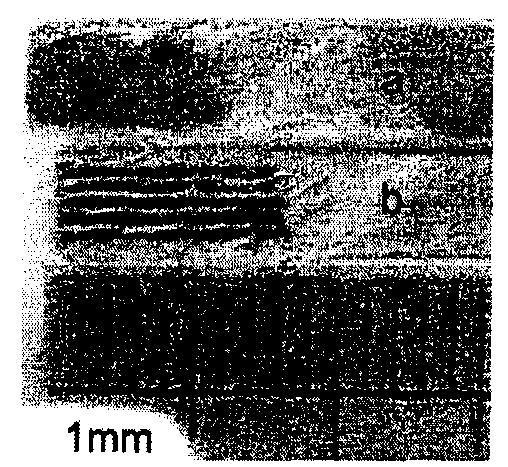

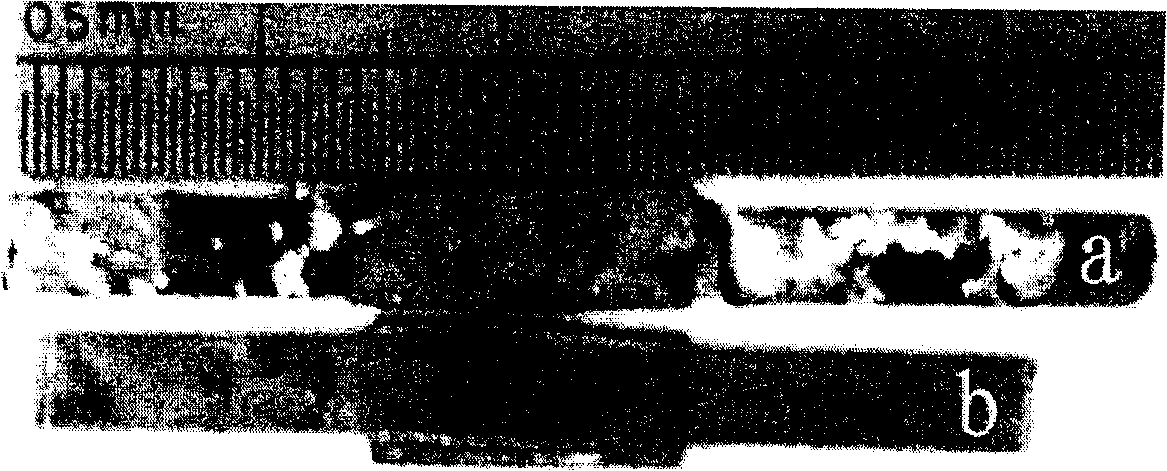

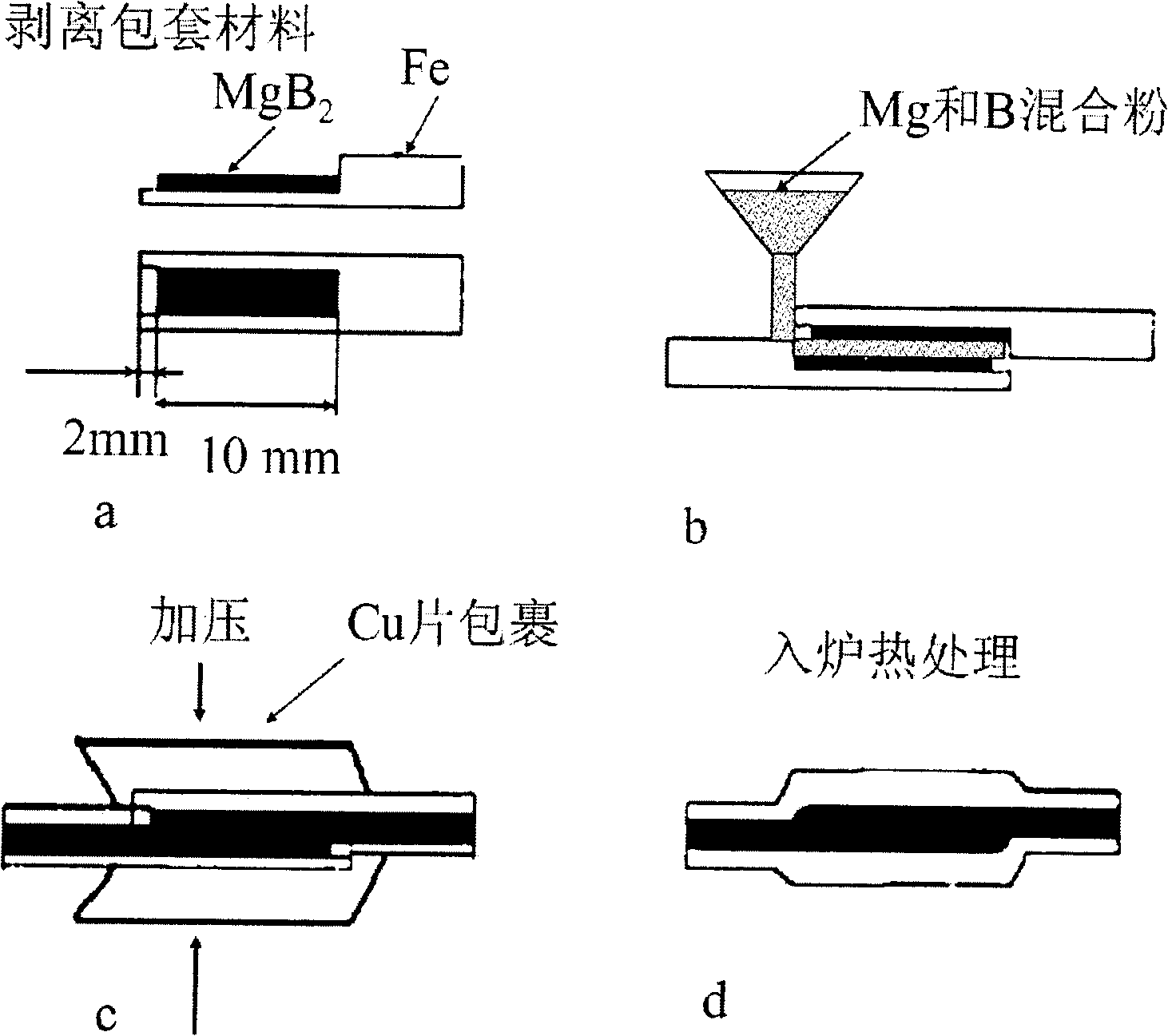

Connecting method of MgB* superconduction in strip shape

InactiveCN101291021AReduce the influence of outside atmosphereImproves mechanical strength and joint densityConnection contact member materialCritical currentHeat treated

The invention provides a superconducting connection method for MgB2 strips. The connection method is characterized in that: a small amount of mixture of Mg powder and B powder is put between two MgB2 strips to be connected; heat treatment is carried out to ensure that molten Mg infiltrates an MgB2 superconducting core of the part to be connected; meanwhile, the molten Mg reacts with B to form MgB2 during the heat treatment; finally, the MgB2 is cooled and then connected with the MgB2 superconducting core. The resistance of a joint part in the invention is below 10 <-11>; the maximum critical current of the joint can reach about 389 A, which is converted into the critical current density of 6.94x10<4>A / cm<2> and is equivalent to the critical current density (about 7x10<4>A / cm<2>) of a complete short sample of the strips in the same batch under the same conditions.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Lateral ankle fusion plate system and jig, and method for use therewith

ActiveUS9421103B2Stable and strong and precise and comfortable for patientEasy to implantAnkle jointsJoint implantsCalcaneusJoint arthrodesis

The invention comprises a lateral ankle fusion plate, a jig for use with the fusion plate and a method for ankle fusion of the joints between the tibia, the talus, and the calcaneus. In addition, a separate fusion screw from posterior to anterior through the calcaneal tuberosity into the distal tibia is useful and can be placed using the targeting jig of the invention. The plate includes a C-shaped stirrup portion that wraps the bottom of the calcaneus and is provided with a screw hole for a T-T-C-fusion screw. A C-shaped targeting jig is provided that interfaces with the plate to allow for placement of the calcaneal screw and has an additional attachment for placement of the independent fusion screw so as to avoid impingement with the plate, and plate screws. The invention also relates to a method of surgery that incorporates the use of the plate, the jig and the tibial / talar / calcaneal fusion screw for an arthrodesis of the ankle joint.

Owner:ORTHOHELIX SURGICAL DESIGNS

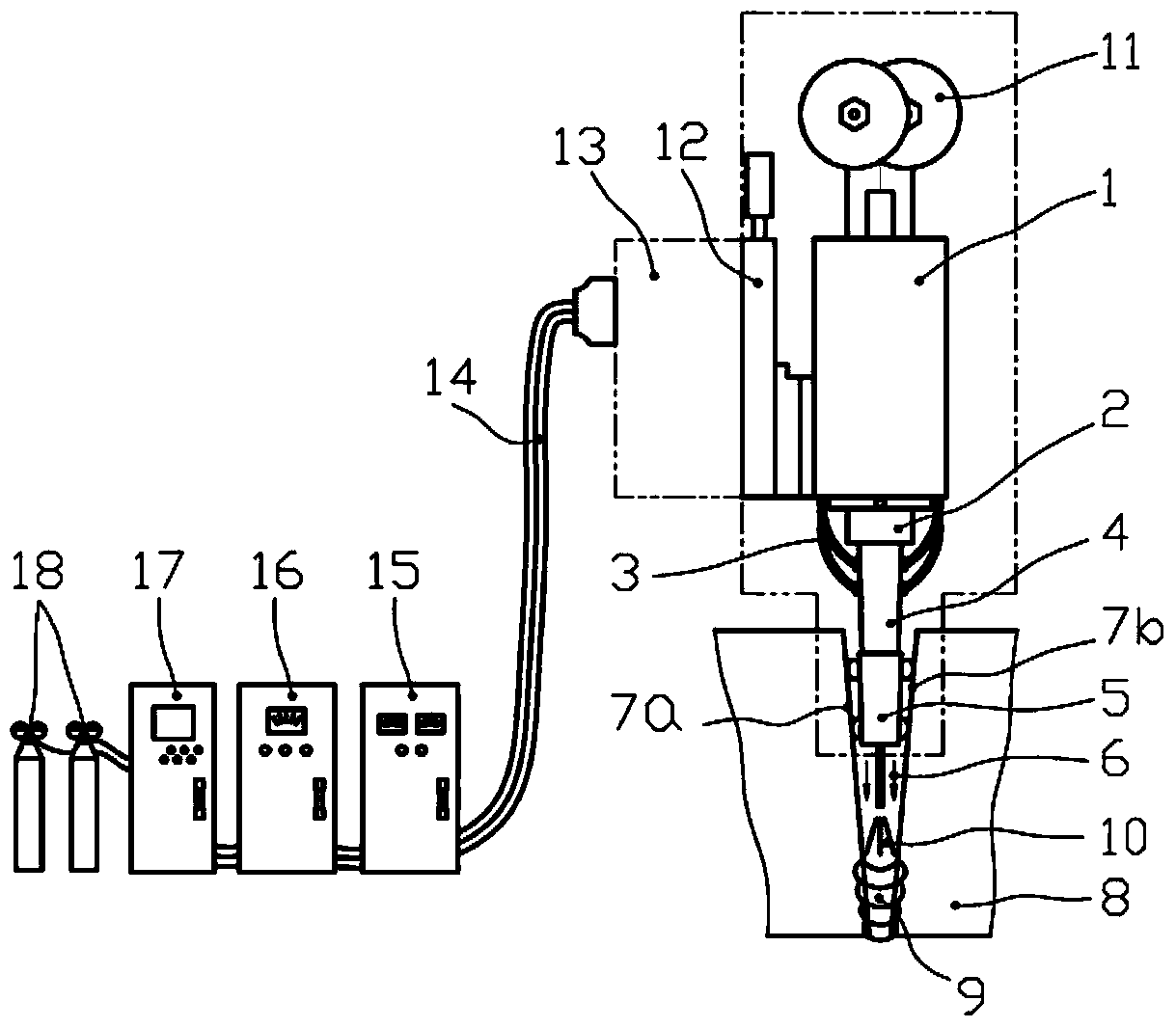

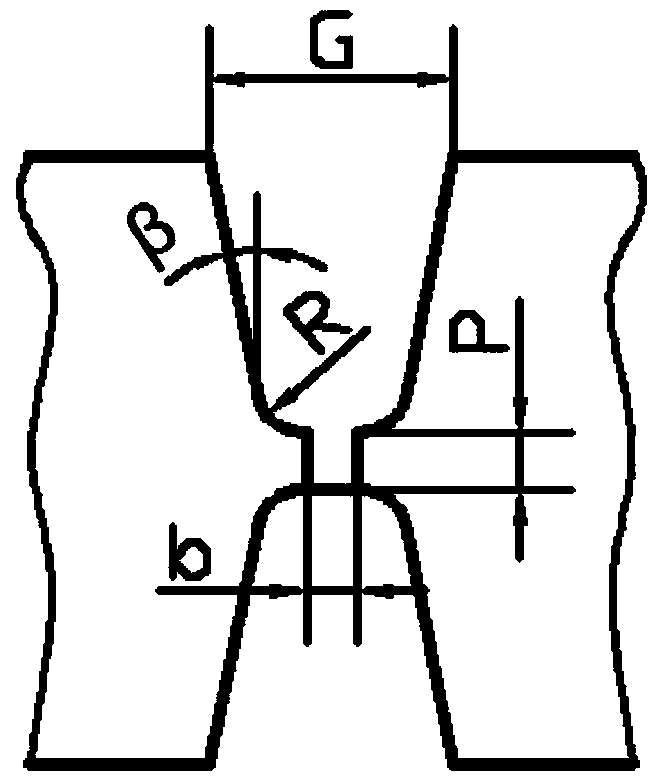

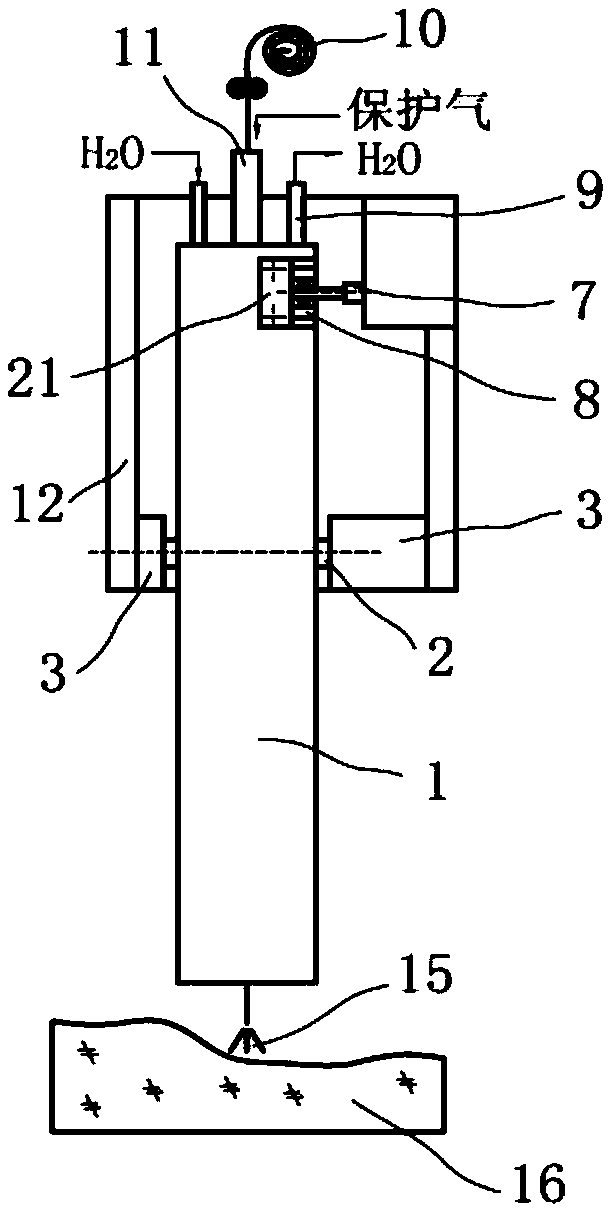

MAG/MIG automatic welding device and method

InactiveCN104289795AImprove reliabilityImprove protectionElectrode supporting devicesWelding coupling meansEngineeringWeld seam

The invention relates to an MAG / MIG automatic welding device and method. The device comprises a wire feeding mechanism, a wire plate is installed at the upper portion of the wire feeding mechanism, and a three-dimensional self-adaptation centering device is installed at the lower portion of the wire feeding mechanism. A plate type welding gun is fixed to the lower portion of the centering device, and a self-adaptation centering sensor is installed at the lower portion of the plate type welding gun. A gas splitting device is arranged in the middle of the lower portion of the welding gun, and the lower portion of the splitting device is connected with a protection nozzle. A welding gun height adjusting mechanism is further included. The welding method includes the steps that welding groove types and sizes, welding wire slip angles and deposition manners are determined, and root gaps, the input power of all welding layers and welding parameters are determined. The MAG / MIG automatic welding device and method have the advantages that self-adaptation intelligent tracking of welding seam tracks under various MAG / MIG welding groove conditions can be achieved, the ultra low welding spattering rate is achieved, welding high-temperature areas under various welding technology conditions can be effectively and reliably protected, the device is durable, high in welding quality, stable, reliable and high in working efficiency, and the welding production cost is greatly lowered.

Owner:武汉纳瑞格智能设备有限公司

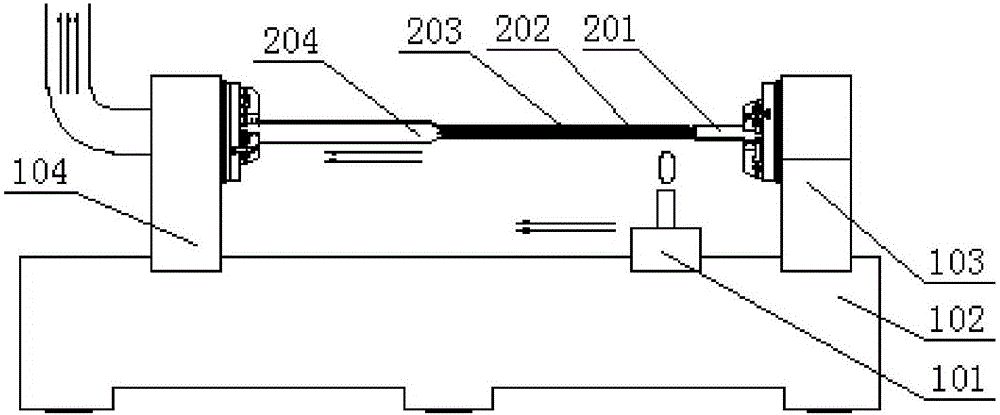

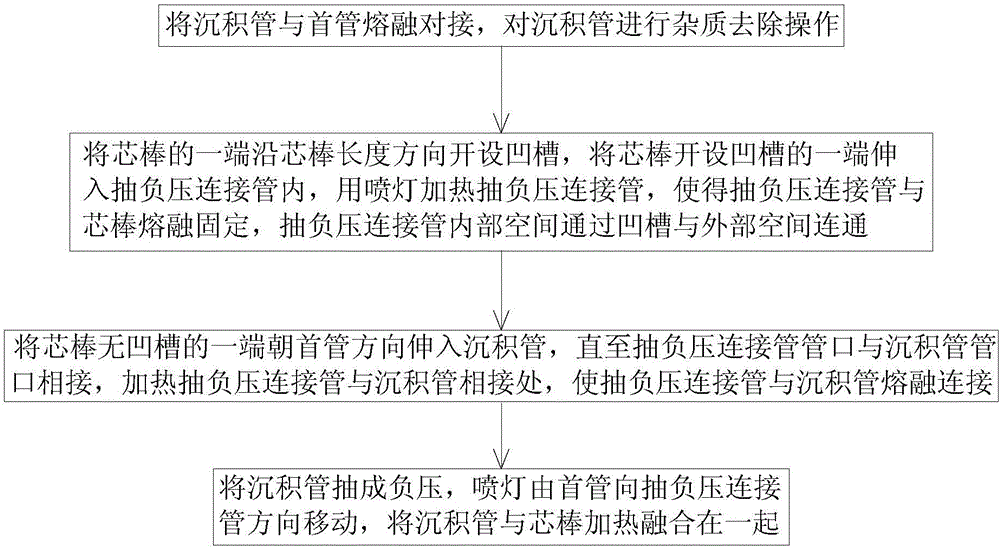

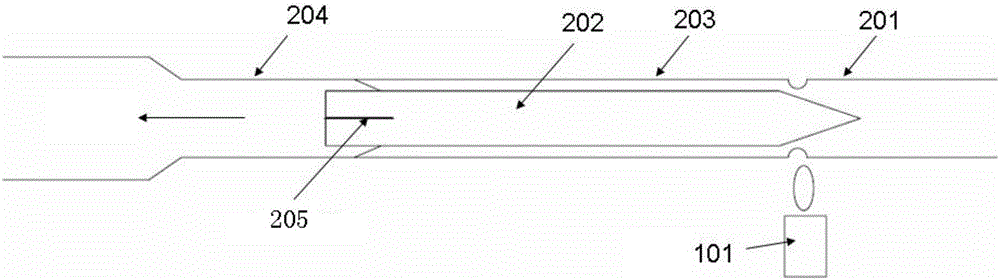

Method for preparing doped optical fiber outer cladding layer

ActiveCN106242262AQuality assuranceImprove the effect of impurity removalGlass making apparatusPressure systemEngineering

The invention discloses a method for preparing a doped optical fiber outer cladding layer, and the method comprises the following steps: 1) a deposition tube and a head tube are butted by fusion, and impurities are removed; 2) one end of a core rod is provided with a groove along the length direction of the core rod, the end, which is provided with the groove, of the core rod stretches into a negative pressure suction connection pipe, and the negative pressure suction connection pipe is heated for fusion fixing with the core rod; 3) one end, which is not provided with the groove, of the core rod stretches into the deposition tube toward the direction of the head tube, and the opening of the deposition tube is heated for sealed connection of the negative pressure suction connection pipe and the deposition tube; 4) the pressure of the deposition tube is pumped to a negative pressure, a blast burner moves from the head tube to the direction of the negative pressure suction connection pipe for heating to fuse the deposition tube and the core rod together. Through arrangement of the groove on one end of the core rod, when air is pumped, the groove plays a key role, air between the deposition tube and the core rod enters the negative pressure suction connection pipe through the groove, and a negative pressure system is formed in the deposition tube, so that the deposition tube and the core rod can be reliably fused.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH +1

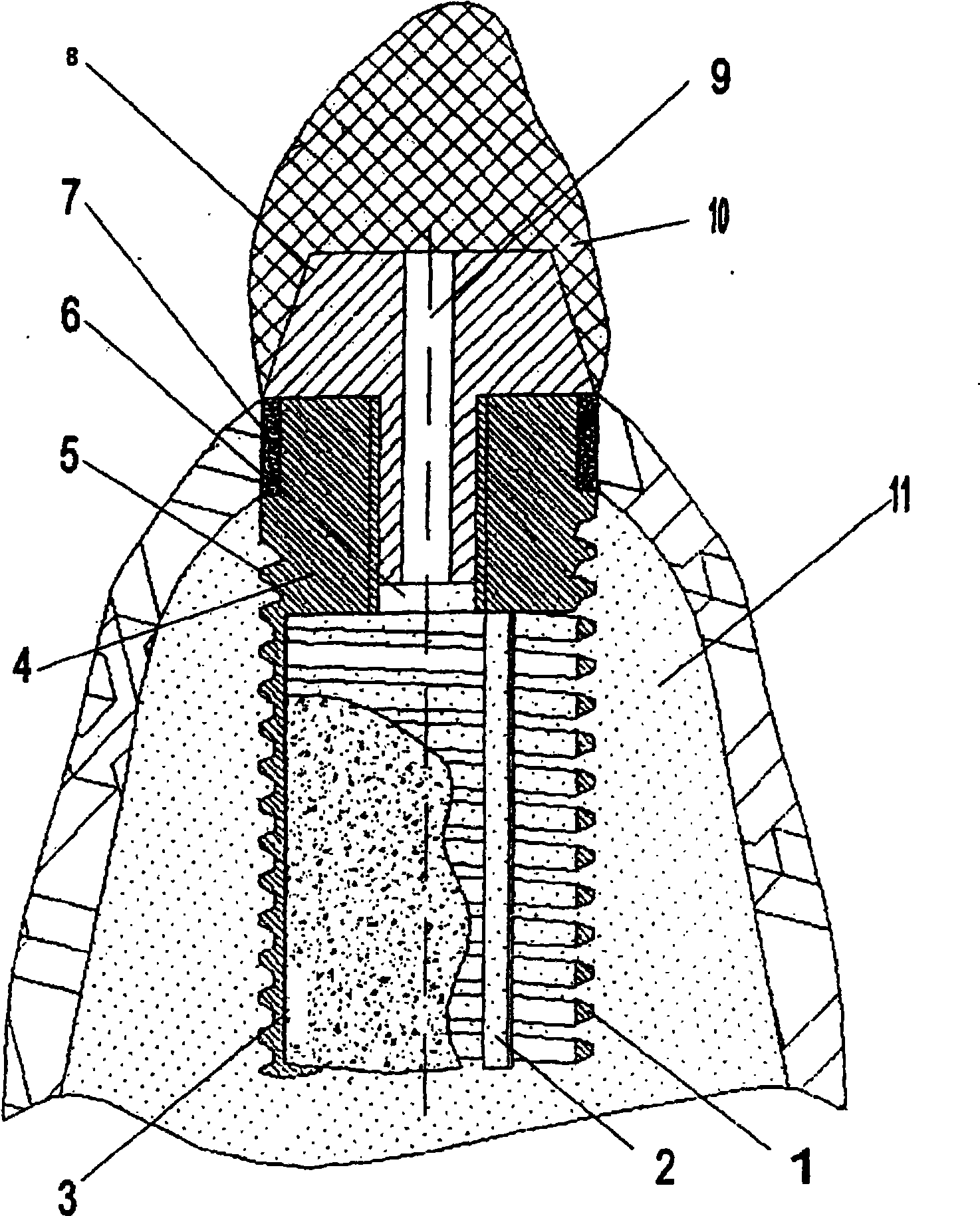

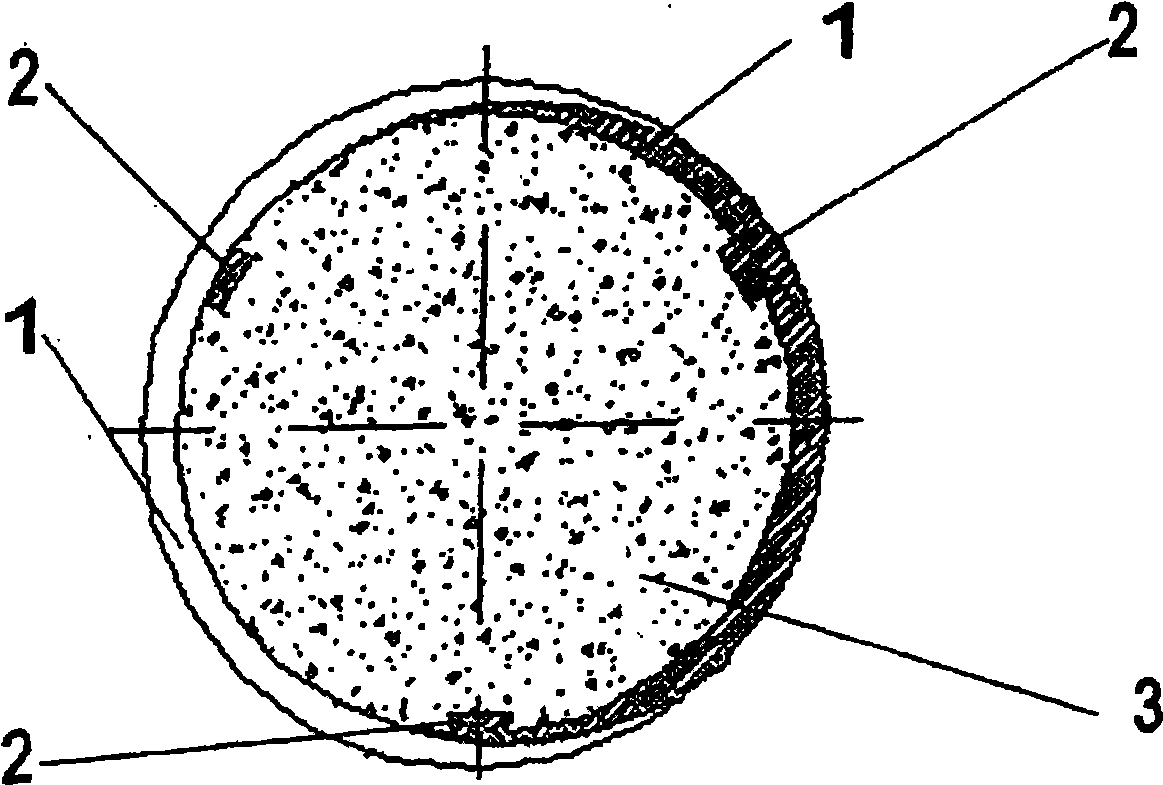

Dental implant

InactiveCN101534742AEasy to fixReliable fusionDental implantsOral administration deviceBone tissueTitanium

The invention relates to dentistry, in particular to a group of dental implants used for two-stage implantation into the alveolar bone. Said invention makes it possible to create the conditions for successful ingrowth of bone and soft tissues into the implant obtainable by the best ingrowth of the bone tissue into the internal porous structure and the soft tissue ingrowth into a surface porous three-dimensional structure in the area of the alveolar bone. The inventive cylindrical implant, the base of which is made of titanium, comprises a cavity for the porous structure and a channel for injecting medicinal preparations, wherein the base is embodied in the form of an external thread-shaped spiral which is fastened to three longitudinal reinforcing ribs arranged inside the spiral together with the porous structure, the pore size of which ranges from 150 to 300 mkm.

Owner:ALTIMED

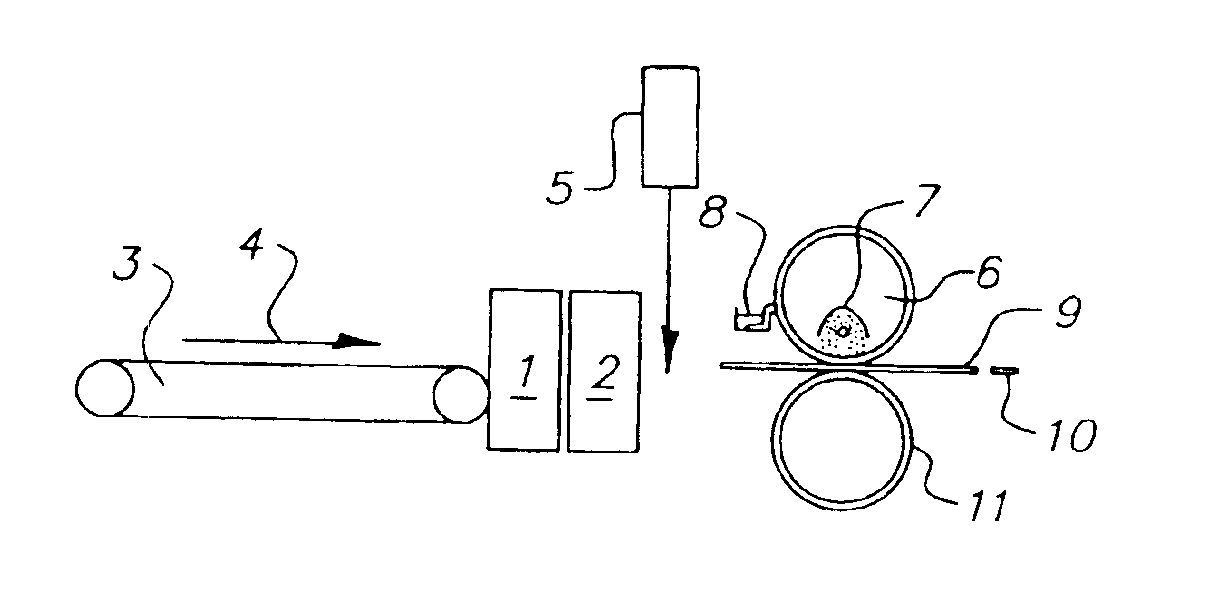

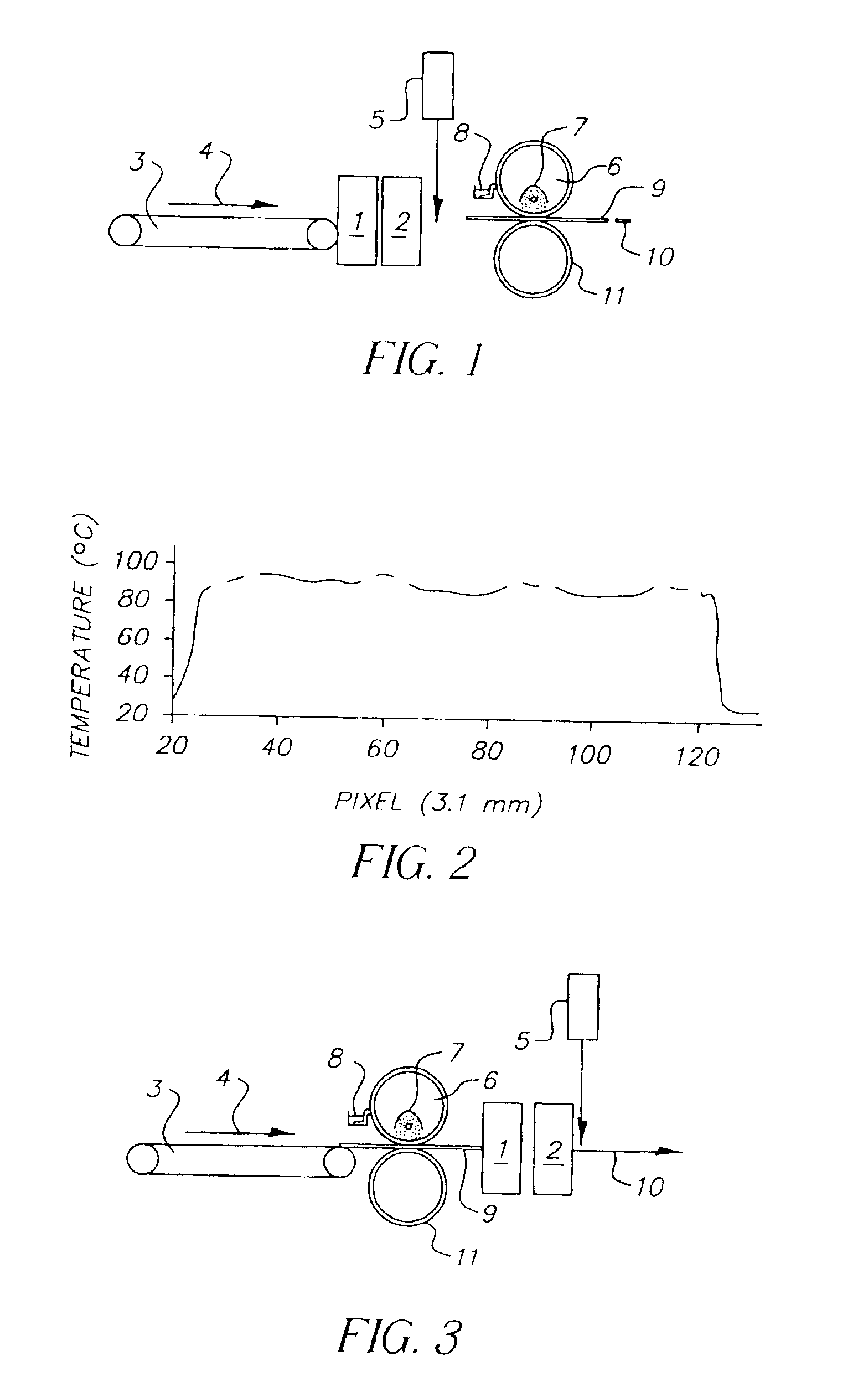

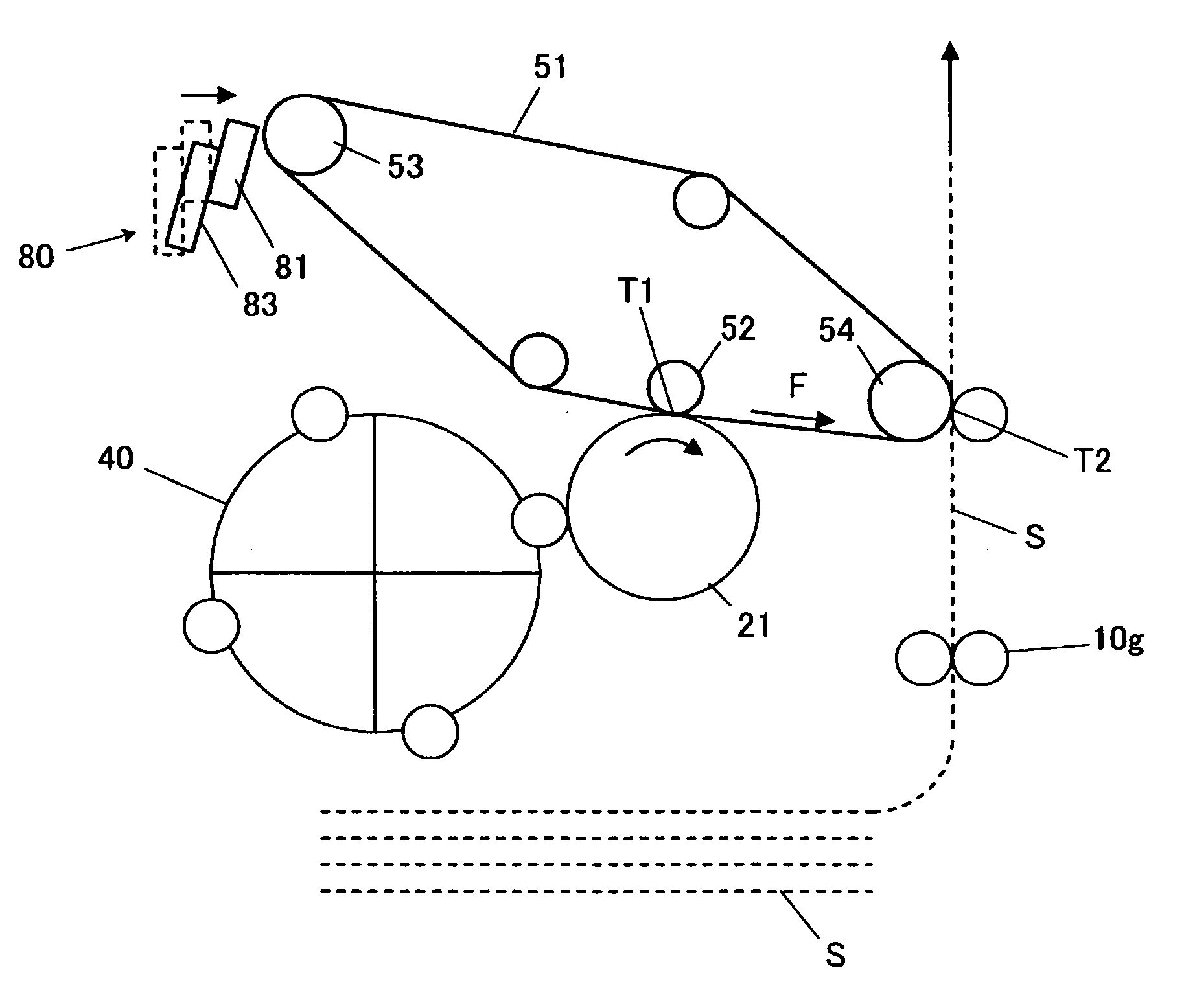

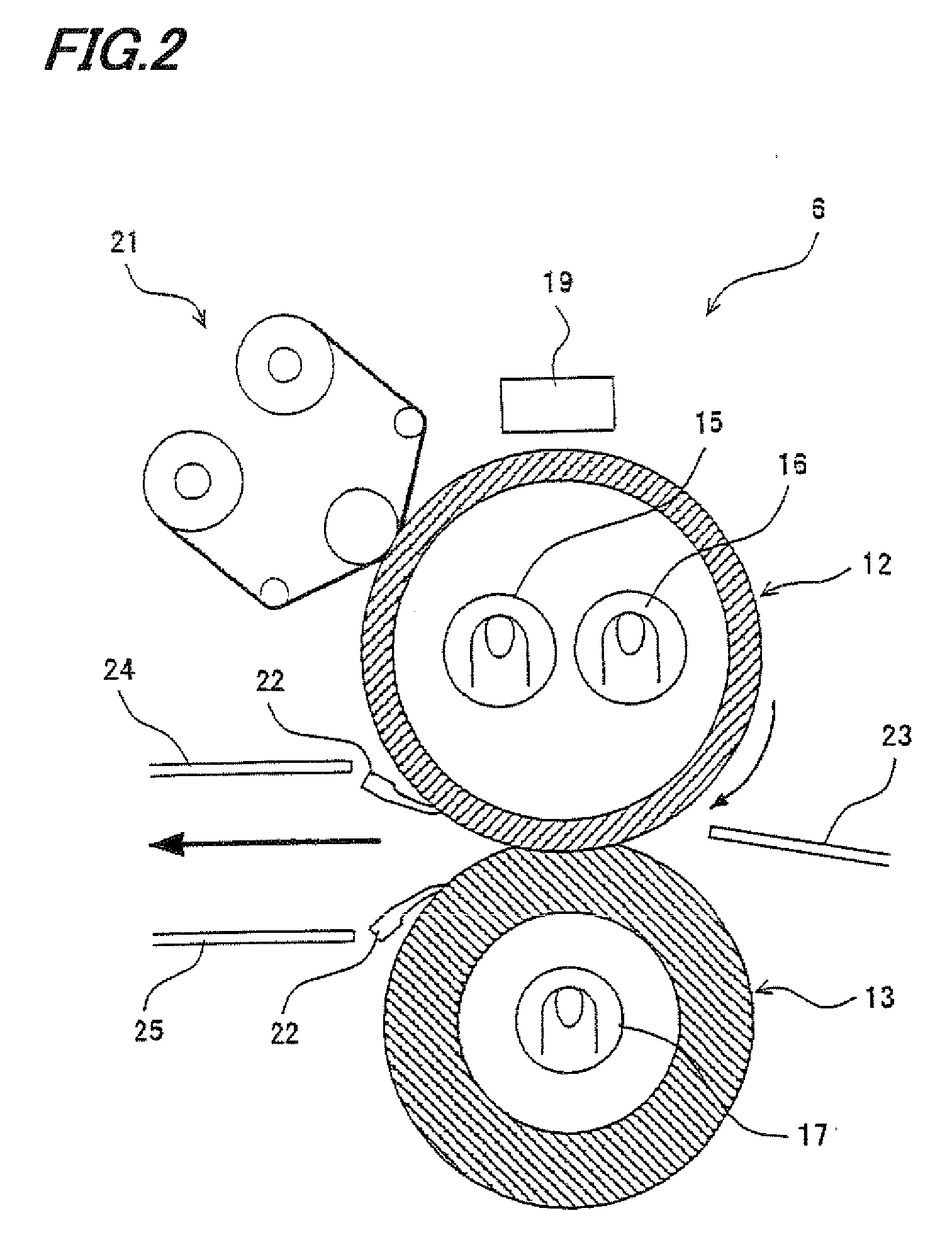

Method and device for fusing toner onto a substrate

InactiveUS6909871B2Increase the electric field strengthImprove efficiencyElectrographic process apparatusMicrowave applicationsElectrical and Electronics engineering

Owner:EASTMAN KODAK CO

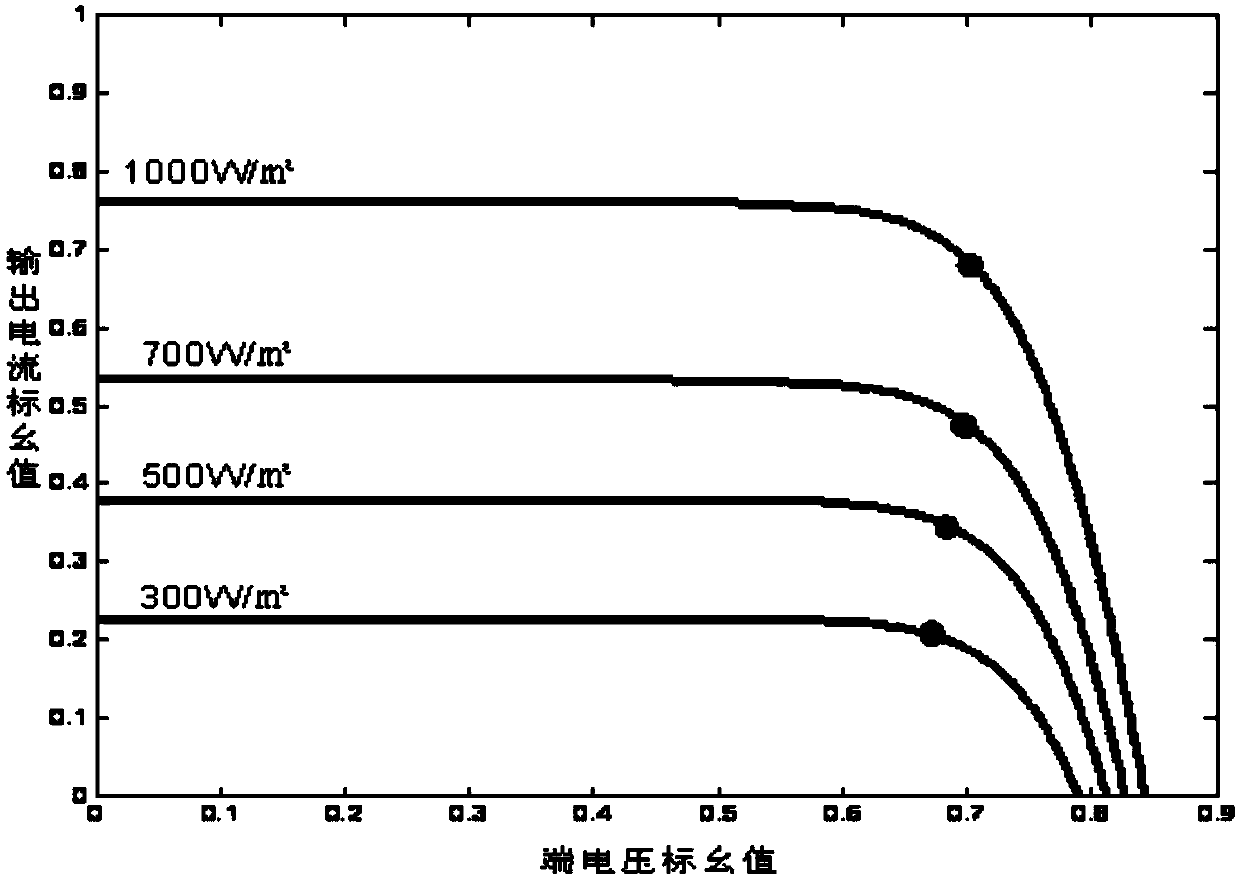

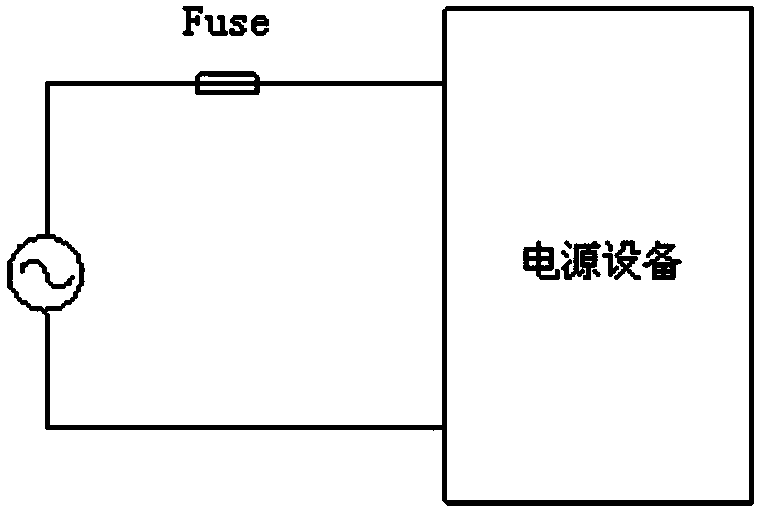

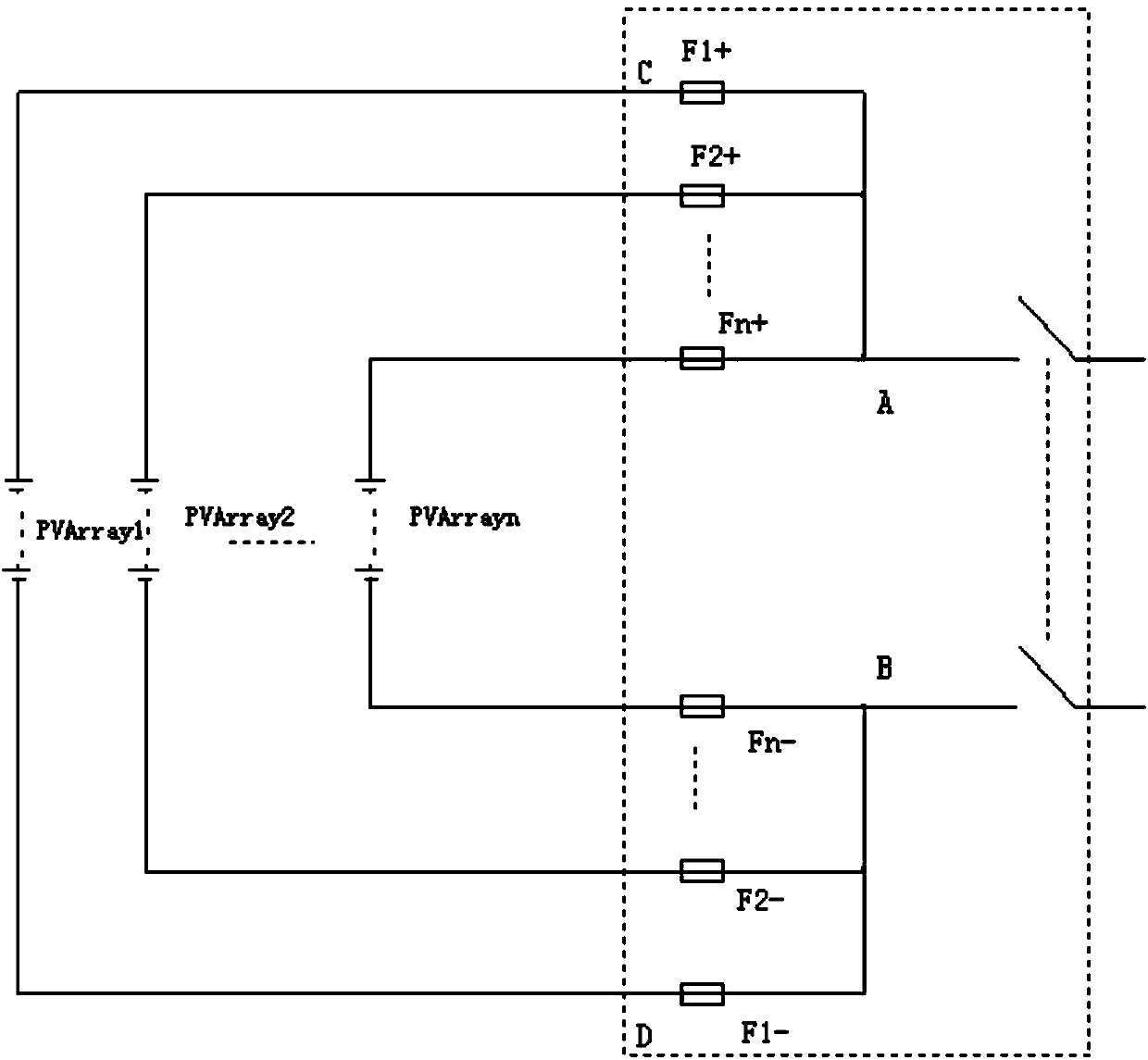

Protective device for photovoltaic power generation system

InactiveCN103595014AExtend working lifeImprove protectionArrangements responsive to excess currentStored energyEngineering

The invention discloses a protective device for a photovoltaic power generation system. The protective device comprises an overcurrent protection unit and an energy storing component, wherein the overcurrent protection unit is connected in series between a photovoltaic assembly and the dc side of a photovoltaic inverter, and the energy storing component is connected in parallel between the photovoltaic assembly and the dc side of the photovoltaic inverter. According to the protective device, the energy storing component is connected in parallel between the photovoltaic assembly and the dc side of the photovoltaic inverter, so that a current source characteristic of a solar cell panel is converted into a voltage source characteristic; when a short-circuit fault occurs in the photovoltaic power generation system, energy stored in the energy storing component can be used to reliably fuse the overcurrent protection unit; such protection is almost not limited by the energy input into the solar cell panel, and can be reliably realized even light is very weak; and the scheme is simple, and protection is reliable.

Owner:SINENG ELECTRIC CO LTD

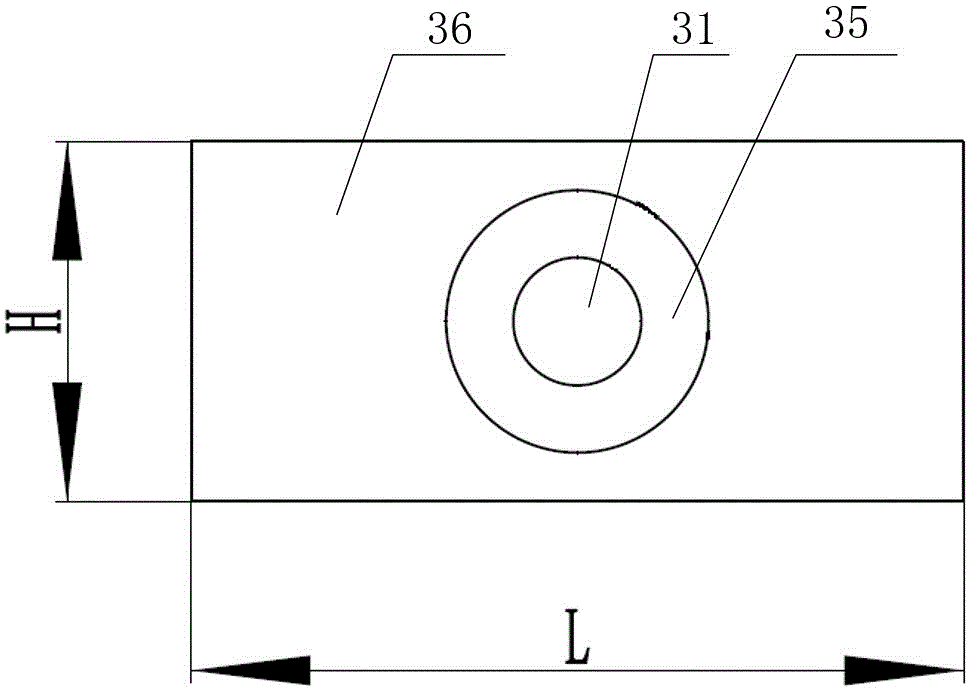

Z-shaped large-caliber plastic pipe connected through inserted electric heat fusion

ActiveCN105135135AImprove pull performanceImprove welding strengthPipe connection arrangementsElectricityButt joint

The invention discloses a Z-shaped large-caliber plastic pipe connected through inserted electric heat fusion. The plastic pipe comprises a pipe body, a socket end, a plug end and an electric heating piece. The socket end is arranged at one end of the pipe body, and the plug end is arranged at the other end of the pipe body. The plug end comprises a first ring face and a second ring face. The diameter of the second ring face is larger than that of the first ring face. A conical transition section is arranged between the first ring face and the second ring face. The socket end comprises a third ring face and a fourth ring face, the diameter of the fourth ring face is larger than that of the third ring face, and a funnel-shaped transition section is arranged between the third ring face and the fourth ring face. The electric heating piece is arranged at the socket end and / or the plug end. The Z-shaped plastic pipe is arranged at the plastic pipe joint. Compared with butt joint heat fusion and parallel inserted electric heat fusion, fusion welding faces are not located on one section and extend to the x direction and the y direction, and the fusion welding strength is greatly improved; and the drawing performance of a pipeline system is improved, and the capability of the pipeline for resisting the surface subsidence is improved.

Owner:张家港戴恩机械有限公司

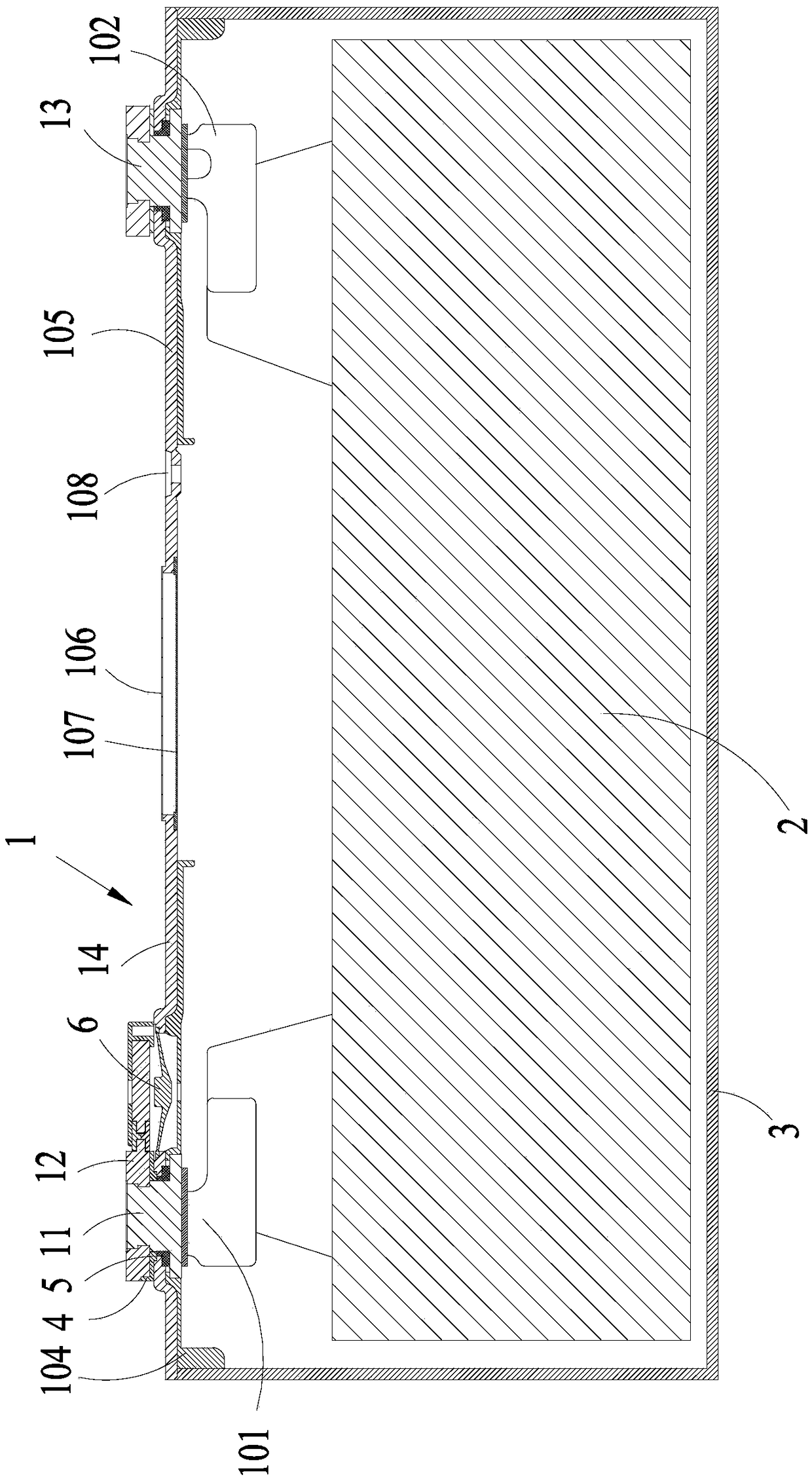

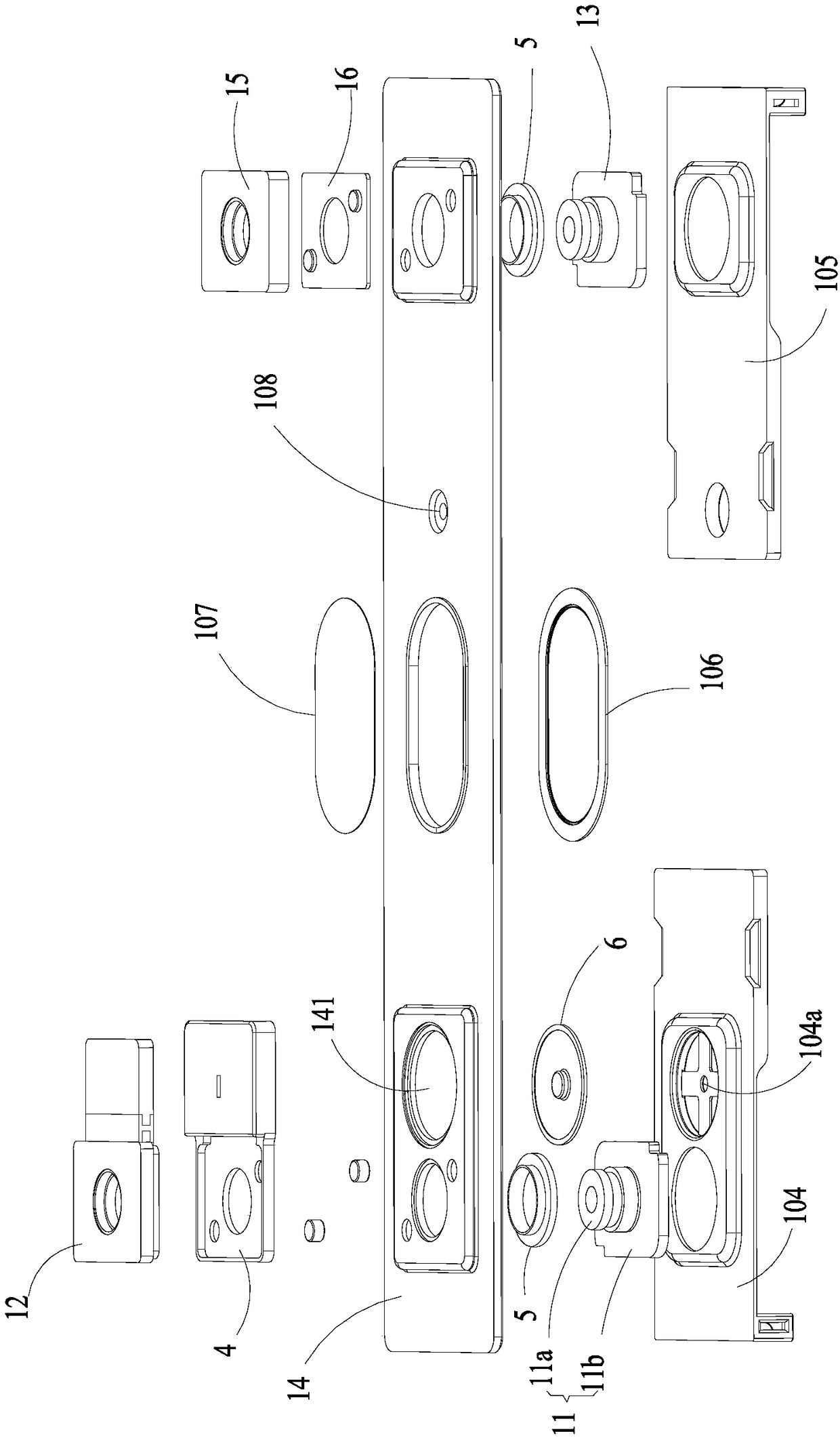

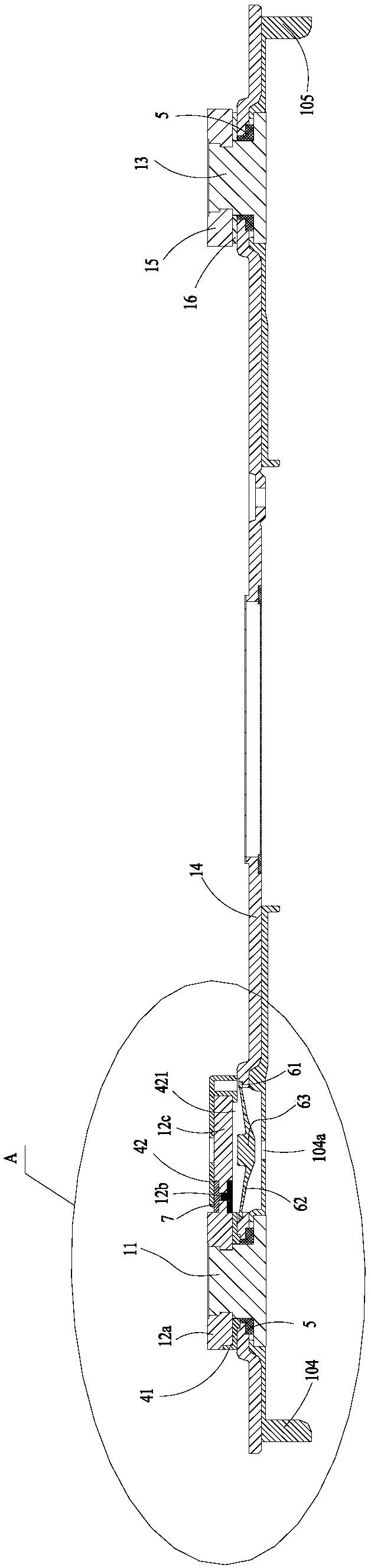

Secondary battery top cover assembly and secondary battery

ActiveCN109285974AImprove securityImprove connection strengthCurrent conducting connectionsCell lids/coversTop capMelting point

The invention relates to a secondary battery top cover assembly and a secondary battery. The secondary battery top cover assembly comprises a first pole, a conductive piece, a second pole and a top cover sheet; the top cover sheet is insulated from the first pole and electrically connected with the second pole; the secondary battery comprises a contact sheet, the contact sheet is attached to the top cover sheet, the conductive piece is is insulated from the top cover sheet and comprises a pole connecting part, a first fuse component and a contact sheet connecting part, and the first fuse component has a fusion point lower than those of the pole connecting part and the contact sheet connecting part; the conductive piece also comprises a connecting layer, and the first fuse component is connected with the pole connecting part through the connecting layer and / or connected with the contact sheet connecting part through the connecting layer. By means of the scheme, the safety of the secondary battery is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Passive middle ear implantation device and preparation method for same

InactiveCN106563808AGuaranteed liquidityAvoid difficultiesTransportation and packagingMetal-working apparatusMiddle earUltimate tensile strength

The invention belongs to the technical field of biomedical engineering and specifically relates to a passive middle ear implantation device and a preparation method for the same. The preparation method comprises the steps that pure titanium powder is mixed with a binder for pelleting, and an injection part is obtained through injection shaping processing; then, the mixture is processed by water de-binding, drying, hot de-binding and pre-sintering successively; and sintering processing and post-processing are conducted then, so the passive middle ear implantation device can be obtained finally. The method is characterized in that a Micro MIM technology is adopted to adjust and improve aspects such as preparation of fine and pure titanium powder injection materials, auxiliary filling design of dies, de-binding technologies and sintering technologies; the prepared passive middle ear implantation device has bone conductivity as well as excellent mechanical performance, corrosion resistance and bio-compatibility of metal titanium; the device also has strength , tenacity, elasticity modulus and anti-fatigue performance matched with a human bone tissue; and defects in the prior art that the cost is high and efficiency is low can be overcome.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

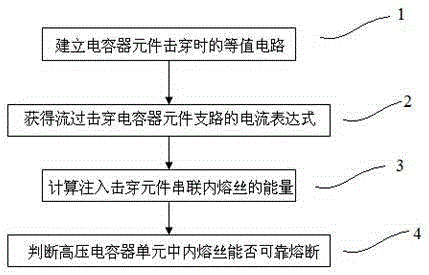

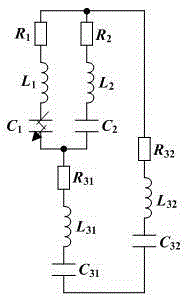

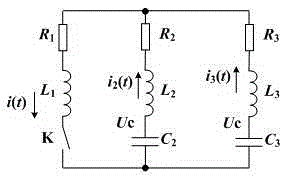

Protection performance verification method for internal fuses of high voltage capacitor unit

ActiveCN105301492AReliable fusionImprove accuracyCircuit interrupters testingElectrical resistance and conductanceInternal resistance

The invention provides a protection performance verification method for internal fuses of a high voltage capacitor unit. The verification method comprises the steps: establishing an equivalent circuit when one capacitor element is broken down in a capacitor unit; solving the equivalent circuit, and acquiring the current expression flowing through a capacitor element subcircuit; according to the current expression and the internal fuse resistance, calculating the energy of the tandem internal fuses, wherein the energy is injected into the capacitor element and breaks down the capacitor element; and determining whether the internal fuses used in the high voltage capacitor unit can be reliably fused by means of combination of the parameters of the whole capacitor device and the material and the size of the internal fuses. The protection performance verification method for internal fuses of a high voltage capacitor unit can accurately determine whether the internal fuses selected by the high voltage capacitor unit can be reliably fused, and can provide reliable guarantee for selecting suitable internal fuses for the high voltage capacitor unit.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Connecting method of MgB* superconduction in strip shape

InactiveCN101291021BGuaranteed performanceImproved critical current characteristicsConnection contact member materialElectrical resistance and conductanceCondensed matter physics

The invention provides a superconducting connection method for MgB2 strips. The connection method is characterized in that: a small amount of mixture of Mg powder and B powder is put between two MgB2 strips to be connected; heat treatment is carried out to ensure that molten Mg infiltrates an MgB2 superconducting core of the part to be connected; meanwhile, the molten Mg reacts with B to form MgB2 during the heat treatment; finally, the MgB2 is cooled and then connected with the MgB2 superconducting core. The resistance of a joint part in the invention is below 10<-11>; the maximum critical current of the joint can reach about 389 A, which is converted into the critical current density of 6.94x10<4>A / cm<2> and is equivalent to the critical current density (about 7x10<4>A / cm<2>) of a complete short sample of the strips in the same batch under the same conditions.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Water-proof zipper and its making method

The present invention intends to provide a waterproof slide fastener in which a synthetic resin film is fused to a fastener tape in order to prevent a perforation phenomenon that the synthetic resin film does not exist locally. A laminated synthetic resin film (4) composed of low melting point resin layer (12) having melting point of, for example, 100 DEG C - 140 DEG C and high melting point resin layer (13) having melting point of, for example, 150 DEG C - 230 DEG C is fused to a surface or both surfaces of a pair of the fastener tapes (3) with the low melting point resin layer (12) being in contact with and opposing the fastener tape (3) by heating with pressure. Fastener elements (5) are mounted onto a side edge (11) of the fastener tape (3) and the laminated synthetic resin film (4) is formed so as to protrude outward from the side edge (11) of the fastener tape (3) and a center point of coupling of the fastener elements (5). Because the high melting point resin layer (13) disposed on the surface of the fastener tape (3) is not melted, no perforation phenomenon occurs. Further, because the laminated synthetic resin film (4) protrudes from the side edge (11), waterproof function is secured.

Owner:YKK CORP

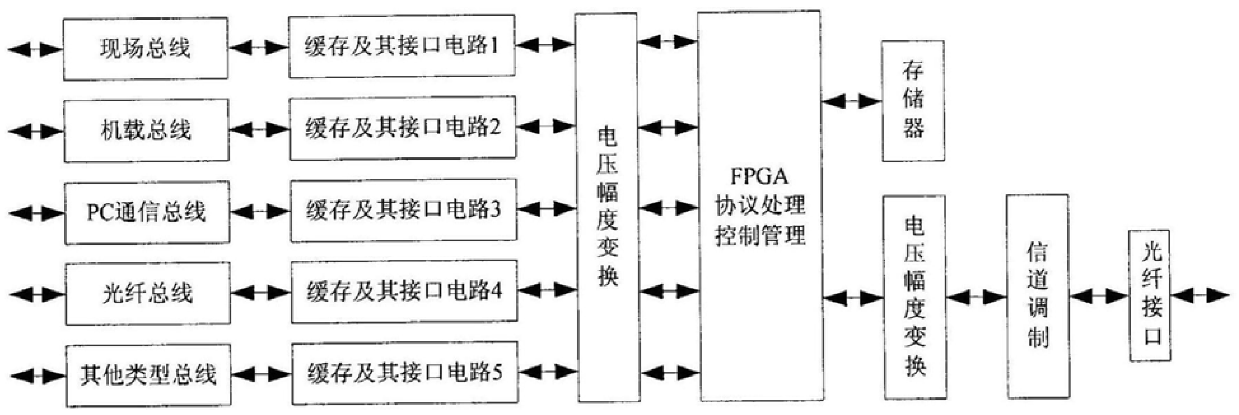

Design method of optical traditional-communication bus coding based on fpga

ActiveCN107211593BReliable fusionImprove confidentialityData representation error detection/correctionData bufferComputer monitoring

The invention relates to an FPGA-based optical traditional-communication bus coding design method, which is used to solve the technical problem of difficulty in interconnecting heterogeneous buses in the prior art. The technical solution is to cache the data of the specific bus through the buffer, and use the buffer as a communication node of the unified bus, perform CMI encoding on the channel in the unified bus to adapt to optical fiber transmission, and use the CCITT-5 standard for CRC check and depth Realize interleaving for 4 memories, thereby improving the fault tolerance of the channel, solving the technical problem of difficult interconnection between heterogeneous buses, and improving the reliability and confidentiality of communication between heterogeneous buses; the present invention encodes the bus data frame format, Realize the control of different nodes and the packet exchange of data, and then enhance the throughput of the system; in order to monitor the communication process and ensure that the upper computer processes and shares the bus data in real time, the present invention adopts the strategy of address comparison to realize the upper computer The monitoring of communication nodes of interest enhances the efficiency of the host computer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

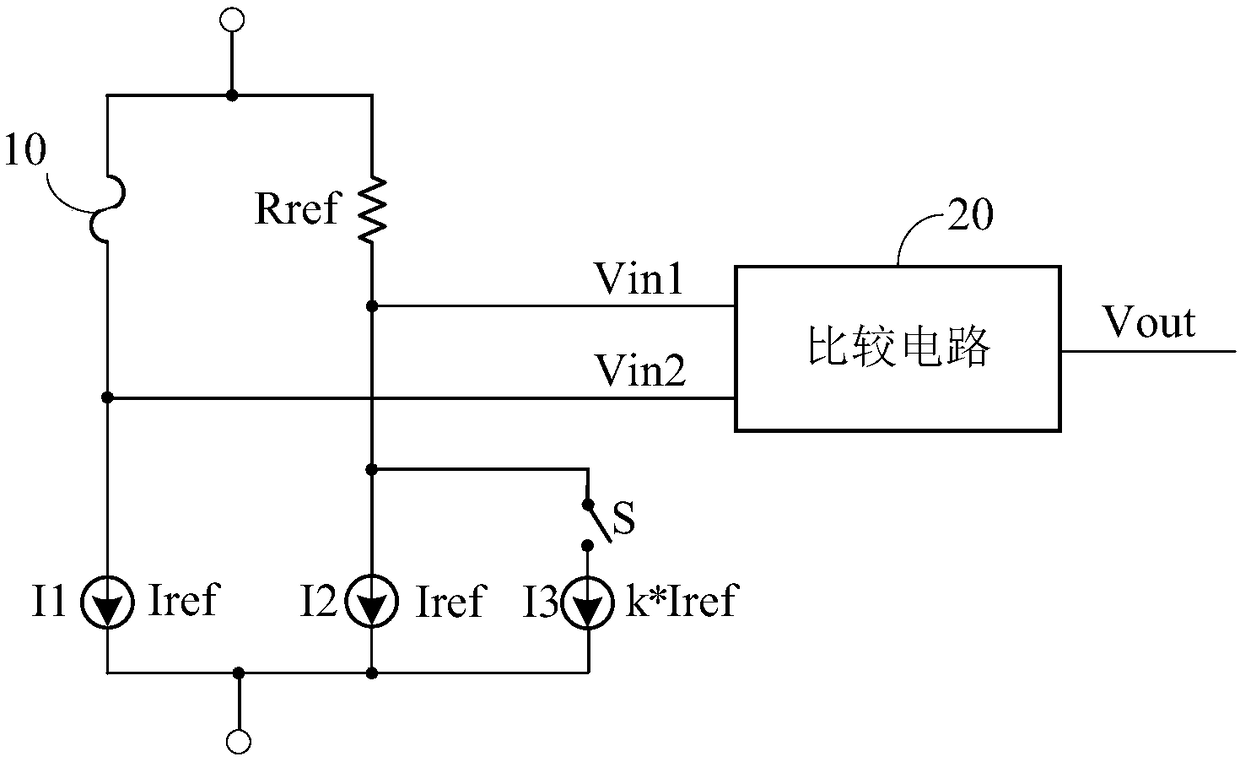

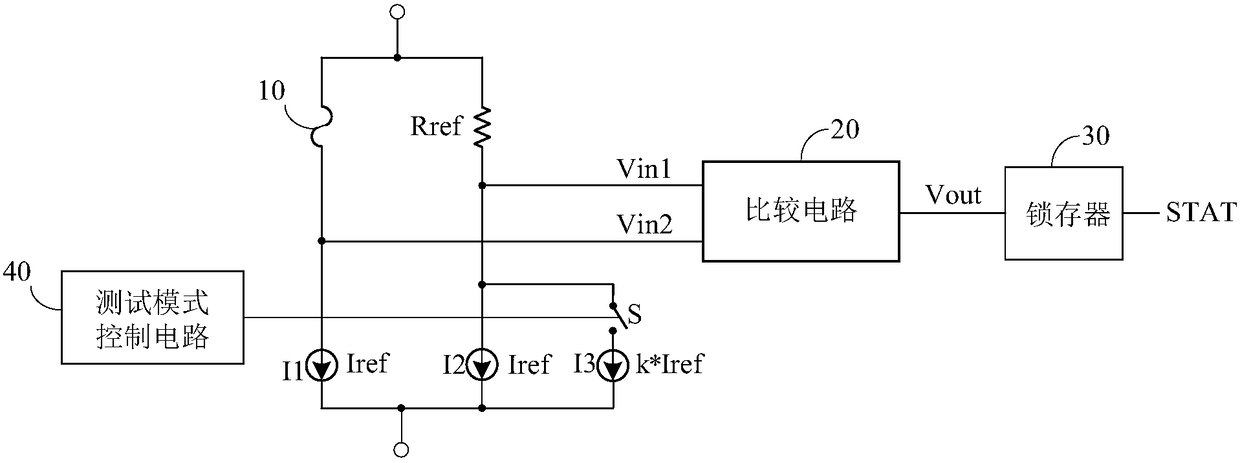

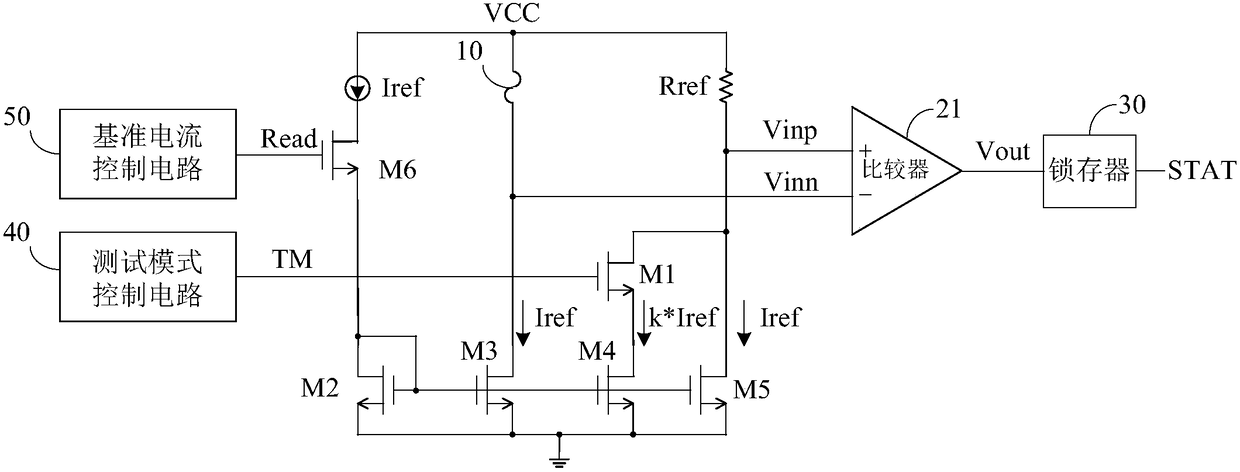

Electric fuse state detection circuit

ActiveCN108089630AWhether it has been fused is accurate and reliableReliable fusionElectric variable regulationElectricityElectrical resistance and conductance

The invention discloses an electric fuse state detection circuit. The circuit comprises an electric fuse, a reference resistor, a first current supply, a second current supply, a third current supply,a switch and a comparison circuit; the comparison circuit generates an output signal according to a voltage value detected by a first input end and a voltage value detected by a second input end, theoutput signal is used for indicating whether the electric fuse is fused or not, wherein current values of the first current supply and the second current supply are referent currents, a current valueof a third current supply is a k-fold referent current, and the switch is closed when the electric fuse is in a test mode. When the electric fuse is in the test mode, the electric fuse can be judgedto be fused when a resistance value of the electric fuse is larger than a resistance value of a (1+k)-fold reference current; therefore, more strict conditions can be provided in the test mode so as to verify whether or not the electric fuse is fused, and therefore it is guaranteed that when a user uses the electric fuse obtained after testing and screening, whether or not the electric fuse is fused can be accurately and reliably judged.

Owner:SHANGHAI AWINIC TECH CO LTD

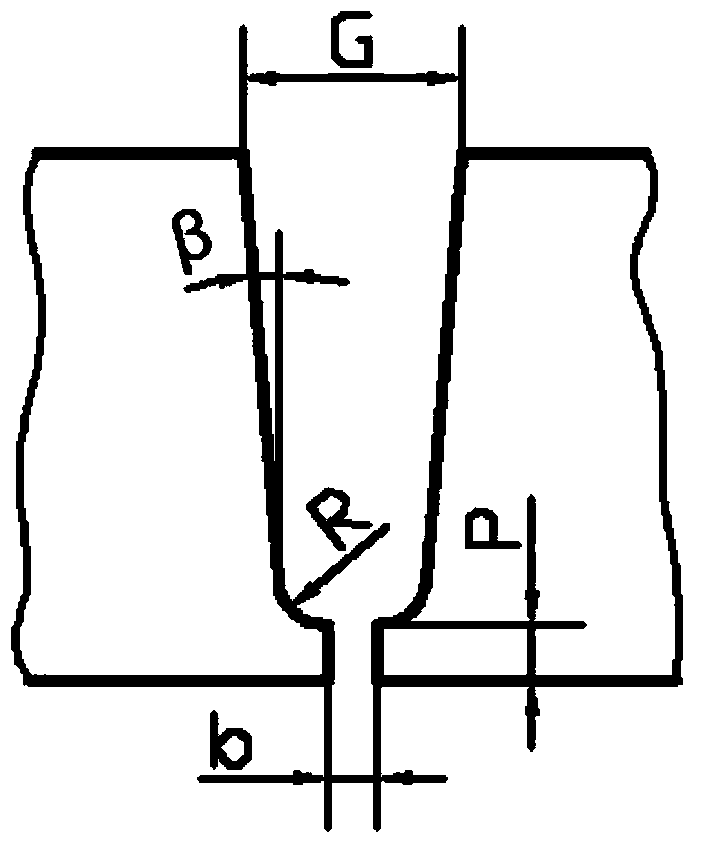

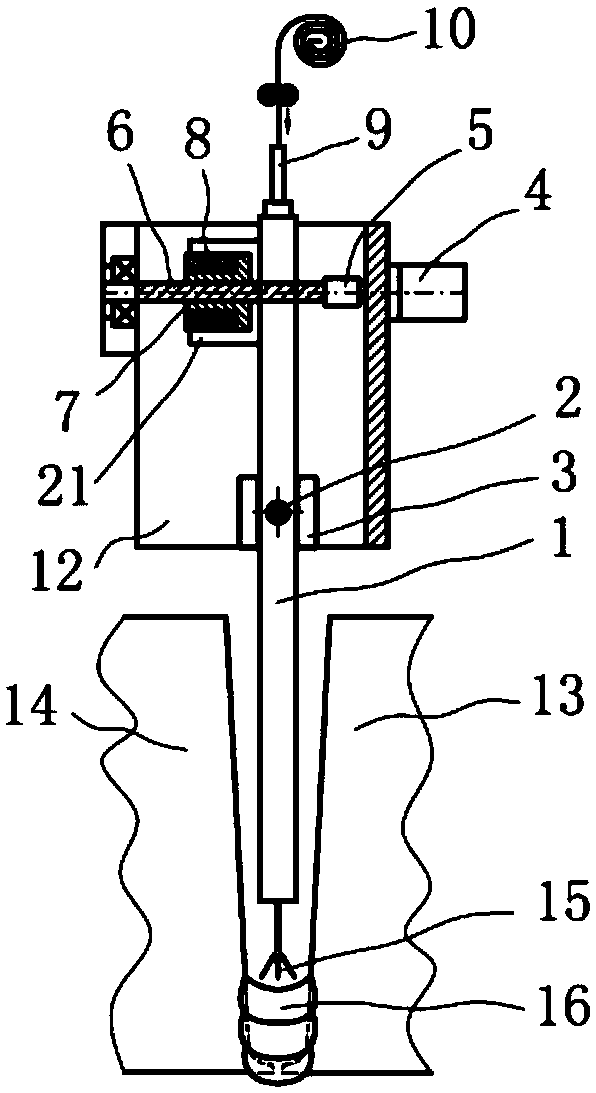

Narrow-gap MAG/MIG automatic horizontal position welding device and method based on welding wire plastic deformation

The invention discloses a narrow-gap MAG / MIG automatic horizontal position welding device based on welding wire plastic deformation, which comprises a front plate type narrow-gap MAG / MIG welding gun and a rear plate type narrow-gap MAG / MIG welding gun, and wire straightening mechanisms are respectively arranged at the adjacent rear parts of wire feeding mechanisms of the front plate type narrow-gap MAG / MIG welding gun and the rear plate type narrow-gap MAG / MIG welding gun; and the front plate type narrow-gap MAG / MIG welding gun and the rear plate type narrow-gap MAG / MIG welding gun are respectively provided with a floating mechanism, an elastic force applying mechanism and a rolling profiling mechanism. A stepless wire straightening method for any position in the circumferential direction of the welding wire is used for adjusting the pointing and acting positions of the welding wire and the electric arc, meanwhile, simultaneous operation of double guns, double wires and double electric arcs is combined, the mechanical self-adaptive tracking technology of elastic floating profiling tracking is adopted, the welding productivity is greatly improved, and meanwhile the welding production cost is greatly reduced.

Owner:武汉纳瑞格智能设备有限公司

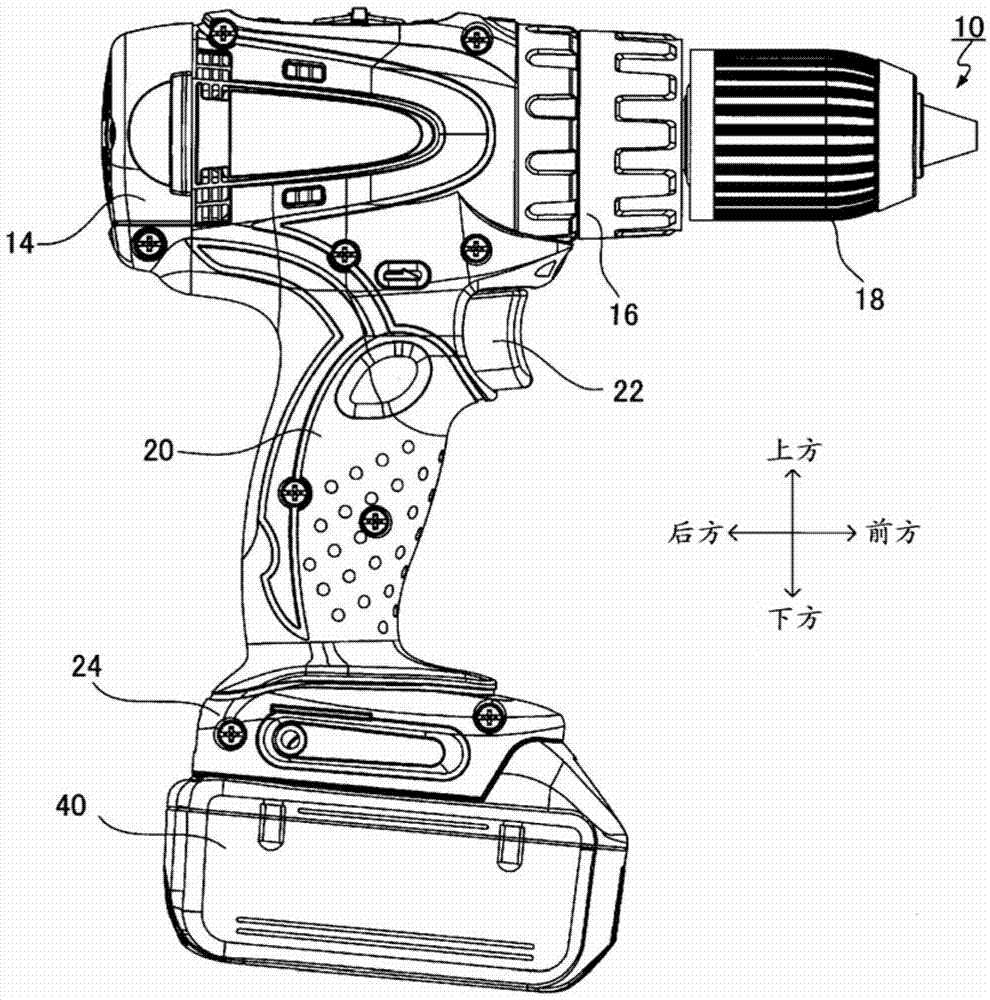

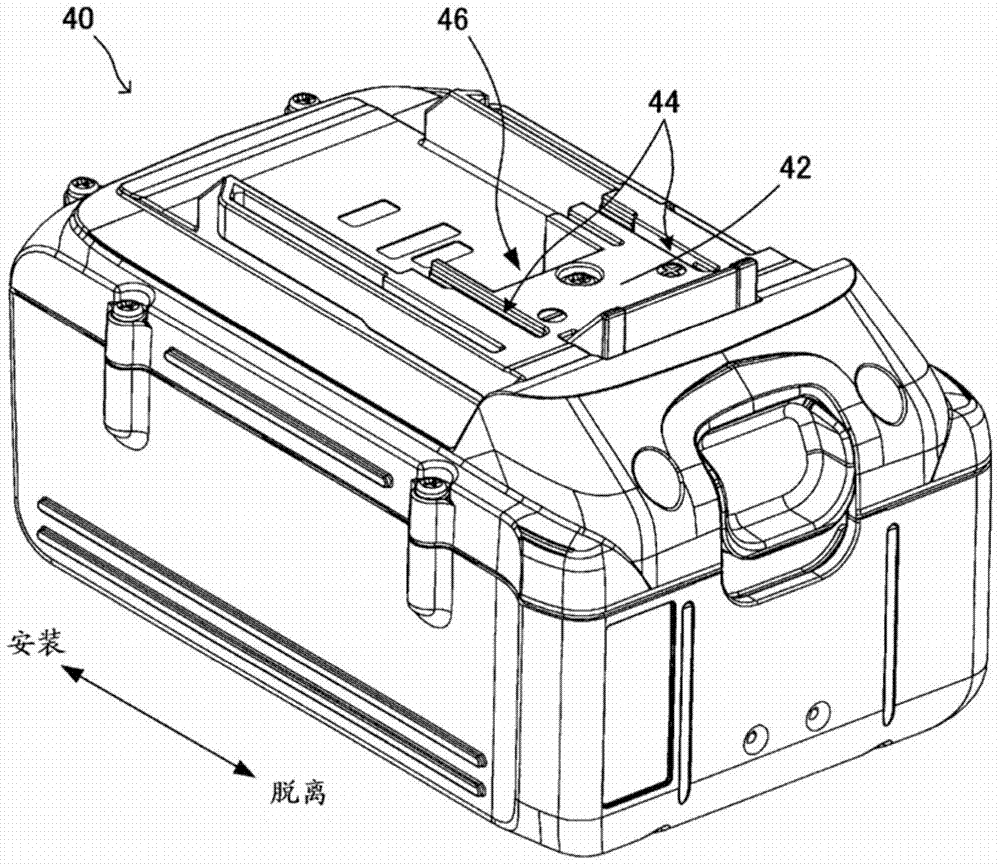

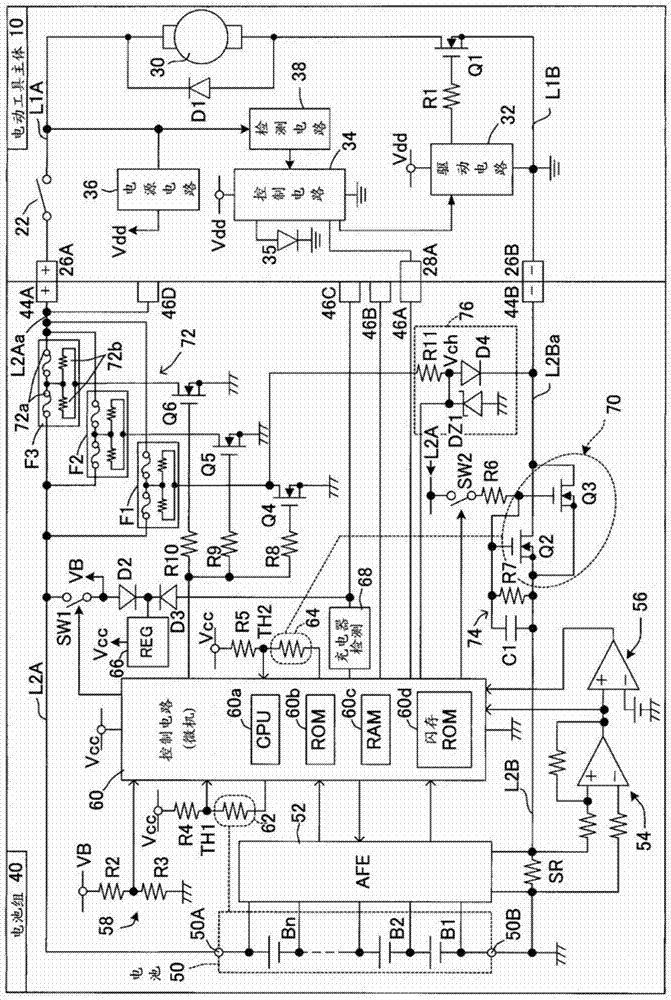

Electrically-driven working apparatus

ActiveCN104779656ALow failure rateSimple compositionCheck valvesPortable power-driven toolsElectrical and Electronics engineeringControl unit

An electrically-driven working apparatus in one aspect of an embodiment of the present disclosure comprises: a battery; an abnormality detection unit; a power supply path; a first disconnection unit; a second disconnection unit; and a control unit. The control unit activates the first disconnection unit to disconnect the power supply path if either of an overload or an over discharge of the battery is detected by the abnormality detection unit, and subsequently determines whether discharge from the battery has stopped after activating the first disconnection unit, and activates the second disconnection unit to disconnect the power supply path if discharge from the battery has not stopped.

Owner:MAKITA CORP

Bridge structure health monitoring system and control method thereof

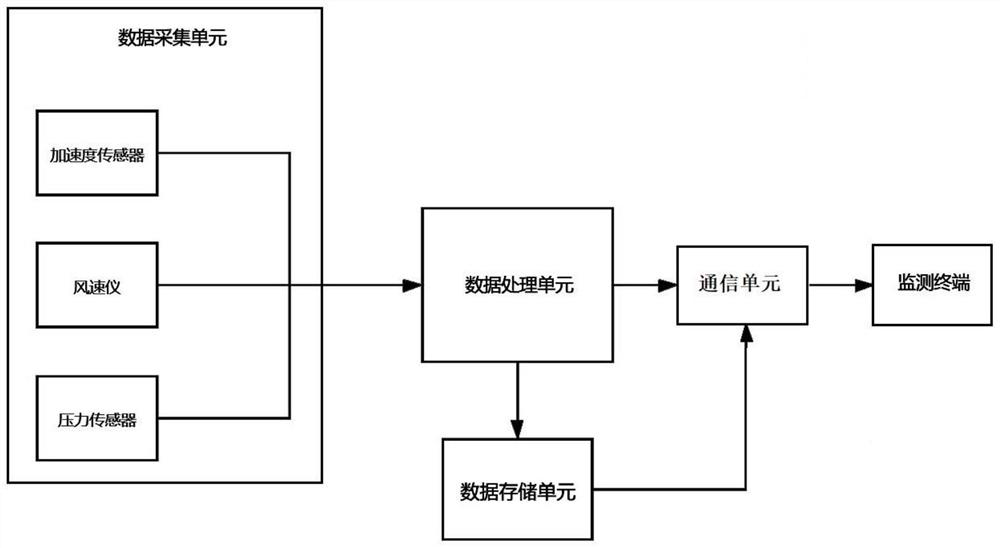

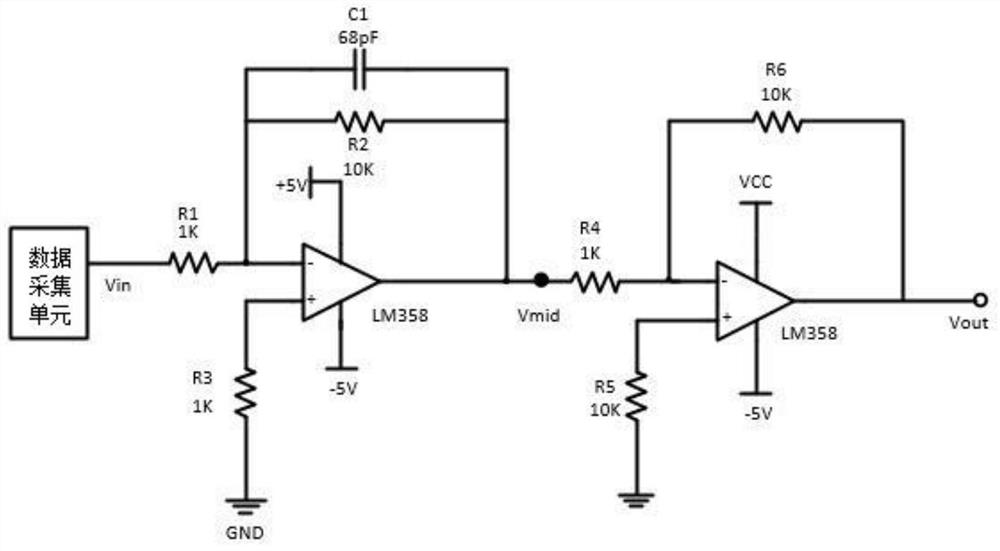

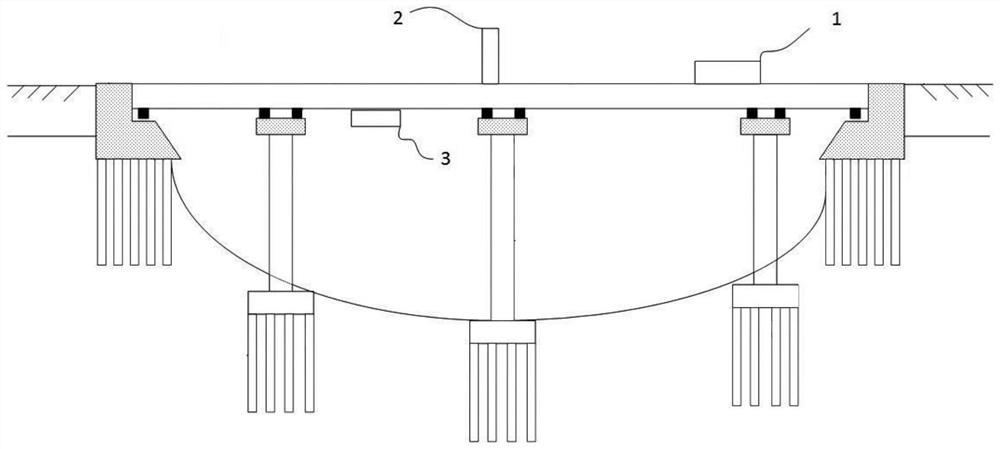

PendingCN112729892AReduce labor costsImprove detection efficiencyStructural/machines measurementData processingData acquisition unit

The invention provides a bridge structure health monitoring system and a control method thereof. The system comprises a data acquisition unit, a data processing unit, a data storage unit, a communication unit and a monitoring terminal, wherein the data acquisition unit comprises an acceleration sensor, an anemograph and a pressure sensor which are arranged on a bridge; the data processing unit comprises an ARM microprocessor, the input end of the ARM microprocessor is connected with the data acquisition unit, and the output end of the ARM microprocessor is connected with the input end of the monitoring terminal through the communication unit; the input end of the data storage unit is connected with the data processing unit, and the output end is connected with the monitoring terminal through the communication unit. According to the invention, automatic real-time regular detection is realized through the monitoring system, traditional manual inspection can be replaced, the labor cost is saved, the manual labor intensity is reduced, the working risk of inspection personnel is reduced, and the detection efficiency is greatly improved.

Owner:南京信息工程大学无锡研究院

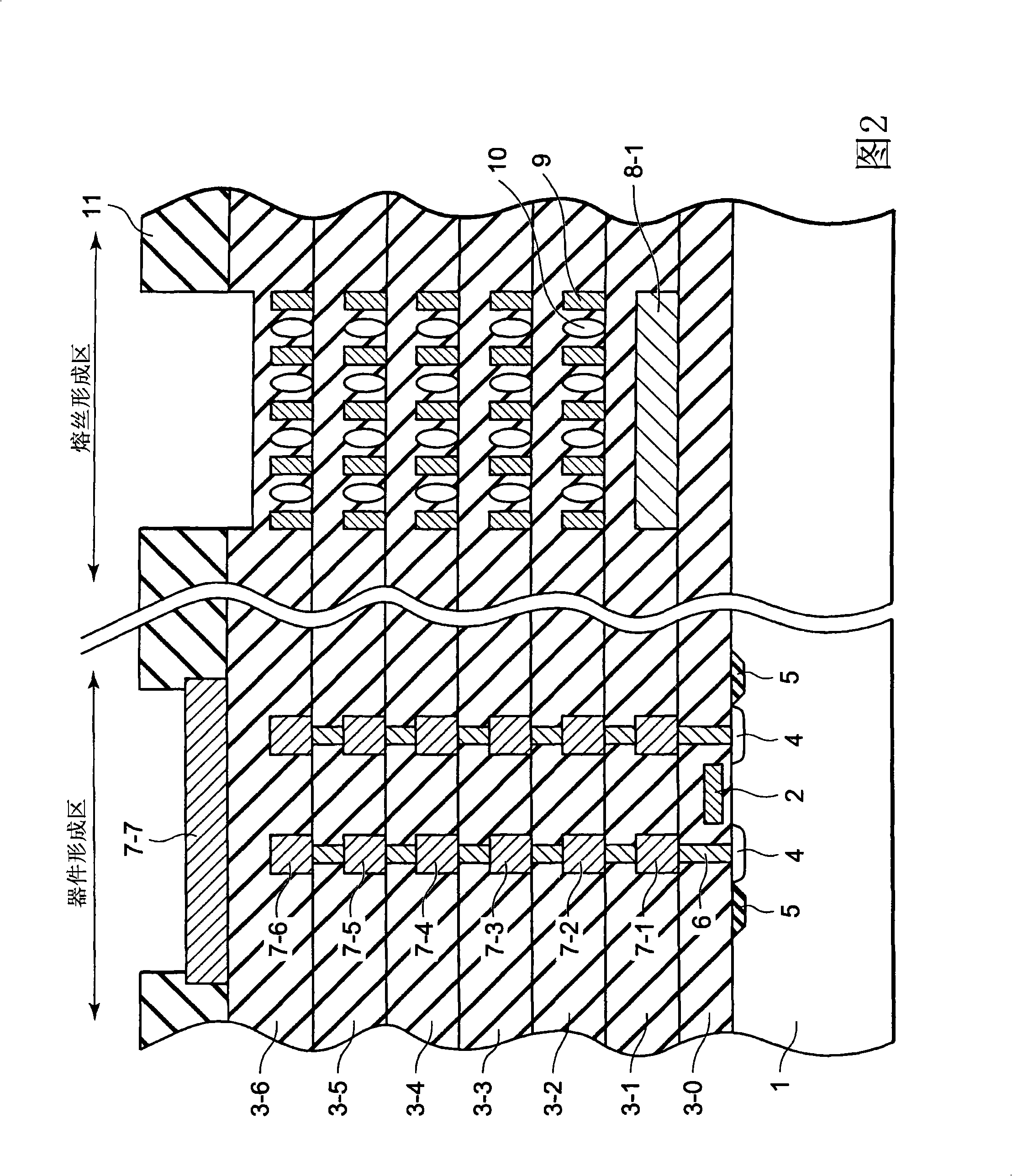

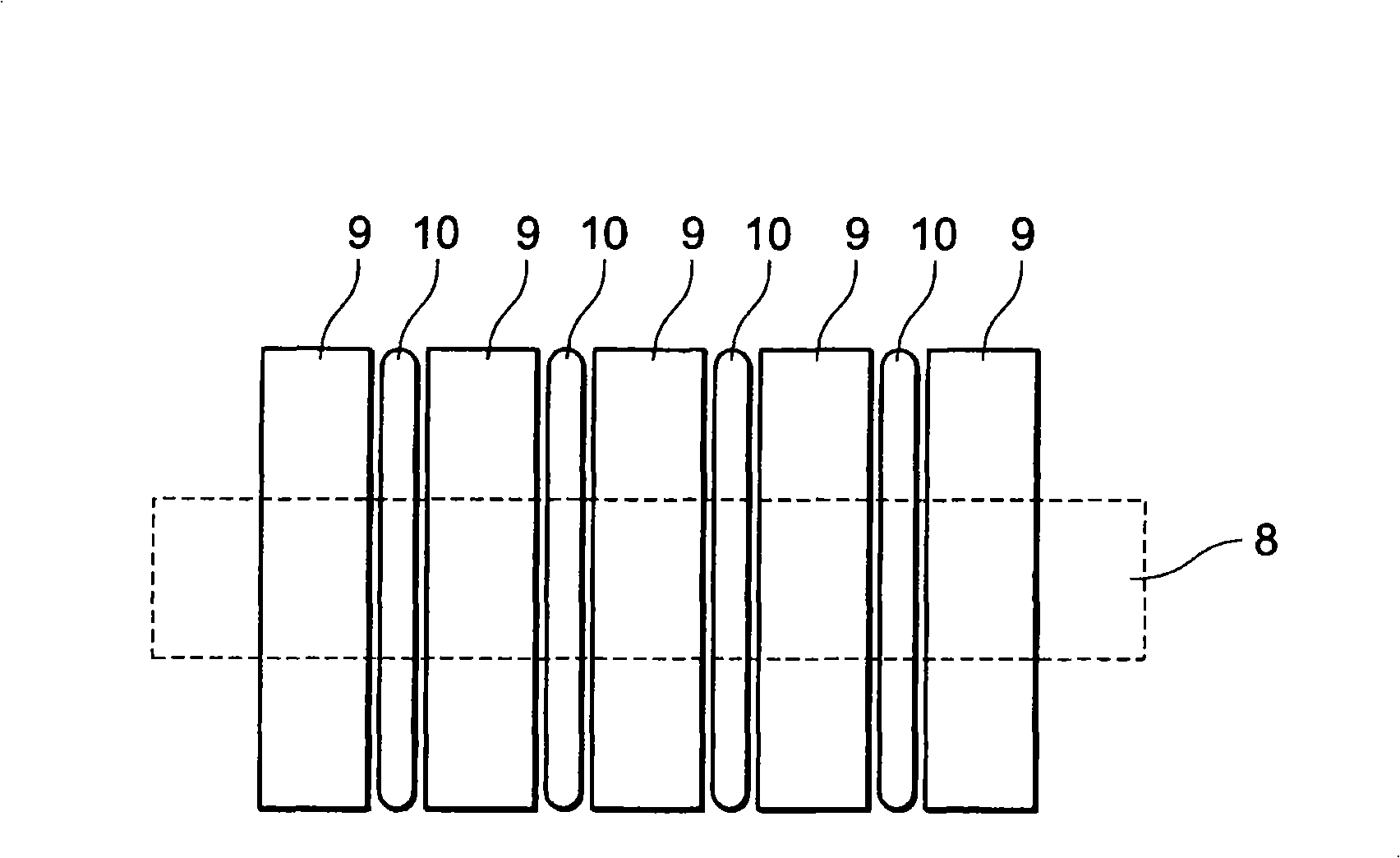

Semiconductor device and method of manufacturing the same

InactiveCN101330073AReliable fusionSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor device in accordance with the present invention includes a fuse formed on a substrate; a first insulator film provided so as to cover the fuse; cavity-forming pattern provided in the layer on the first insulator film; and second insulator film provided so as to cover the cavity-forming pattern, wherein the cavity-forming pattern is patterned so that a spatial area is produced therebetween and the second insulator film covers the cavity-forming pattern so that a cavity is produced in the spatial area.

Owner:NEC ELECTRONICS CORP

Ultra narrow gap MAG/MIG welding two-side wall fusing control device based on welding gun fan-shaped swing

ActiveCN108746937APrecise Swing ControlAvoid asymmetryElectrode supporting devicesGroove widthEngineering

The invention relates to an ultra narrow gap MAG / MIG welding two-side wall fusing control device based on welding gun fan-shaped swing. The ultra narrow gap MAG / MIG welding two-side wall fusing control device comprises ultra narrow gap MAG / MIG welding guns, a fan swing fulcrum mechanism, a fan swing driving mechanism, a pulling gun device and a welding gun outer base; the ultra narrow gap MAG / MIGwelding guns are connected through the fan swing fulcrum mechanism to be driven by the fan swing driving mechanism to do fan-shaped swing in the center in the width direction of a welding groove at the lower edge along a fan swing fulcrum. The ultra narrow gap MAG / MIG welding two-side wall fusing control device has the following advantages that a welding gun fan-shaped swing center can be accurately coincident with the center of a current welding groove, dissymmetry of action distances between electric arcs and the two side walls can be completely prevented, and the condition that a certain side wall is not fused due to not-identical distances between the electric arcs and the side walls can be reliably prevented; during fan-shaped electric arc swing, as electric arc centers with the highenergy density more easily acts on the positions nearby the side walls, the side wall fusing reliability is higher; and self-adaptation control over the swing amplitude and the actual groove width isachieved.

Owner:武汉纳瑞格智能设备有限公司

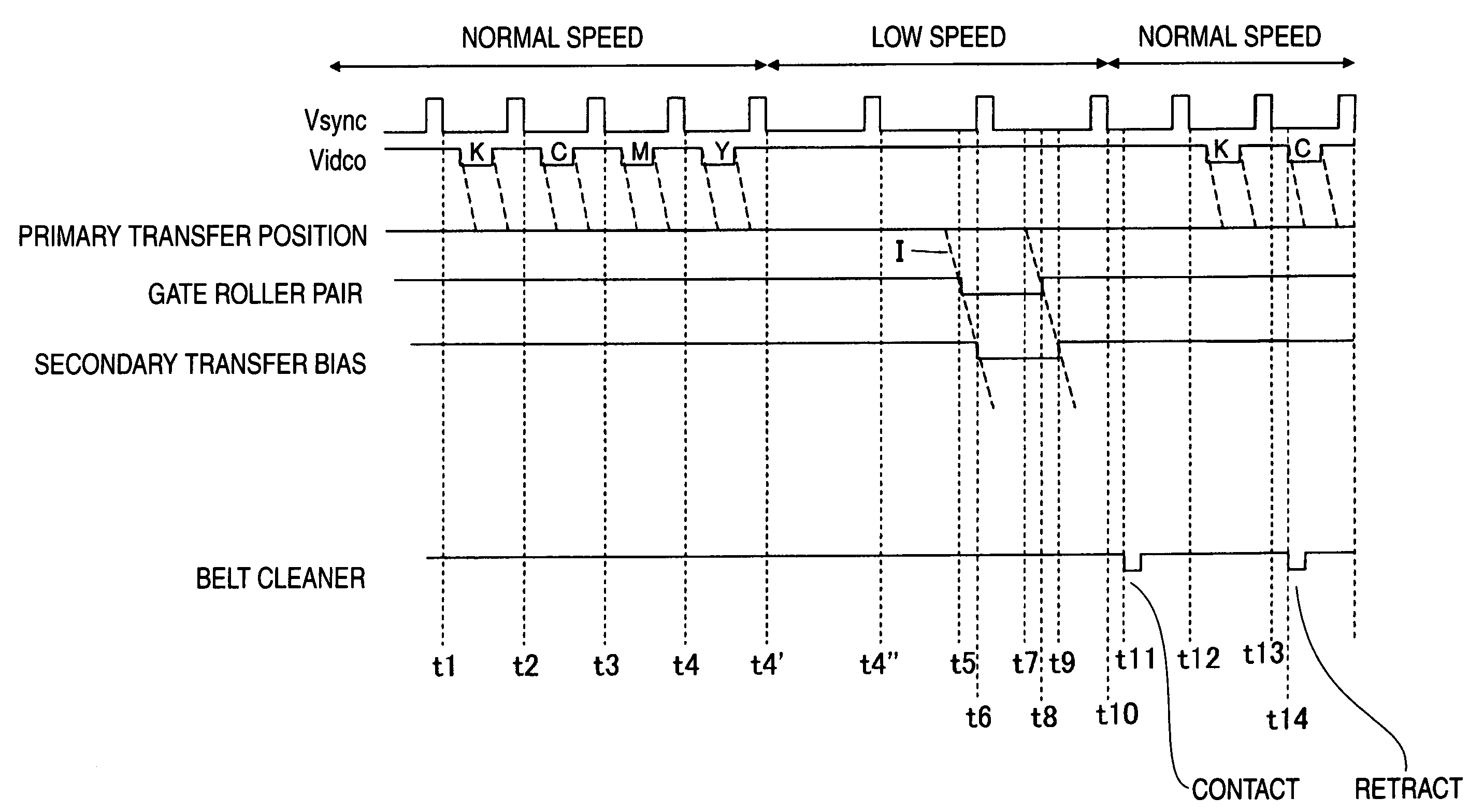

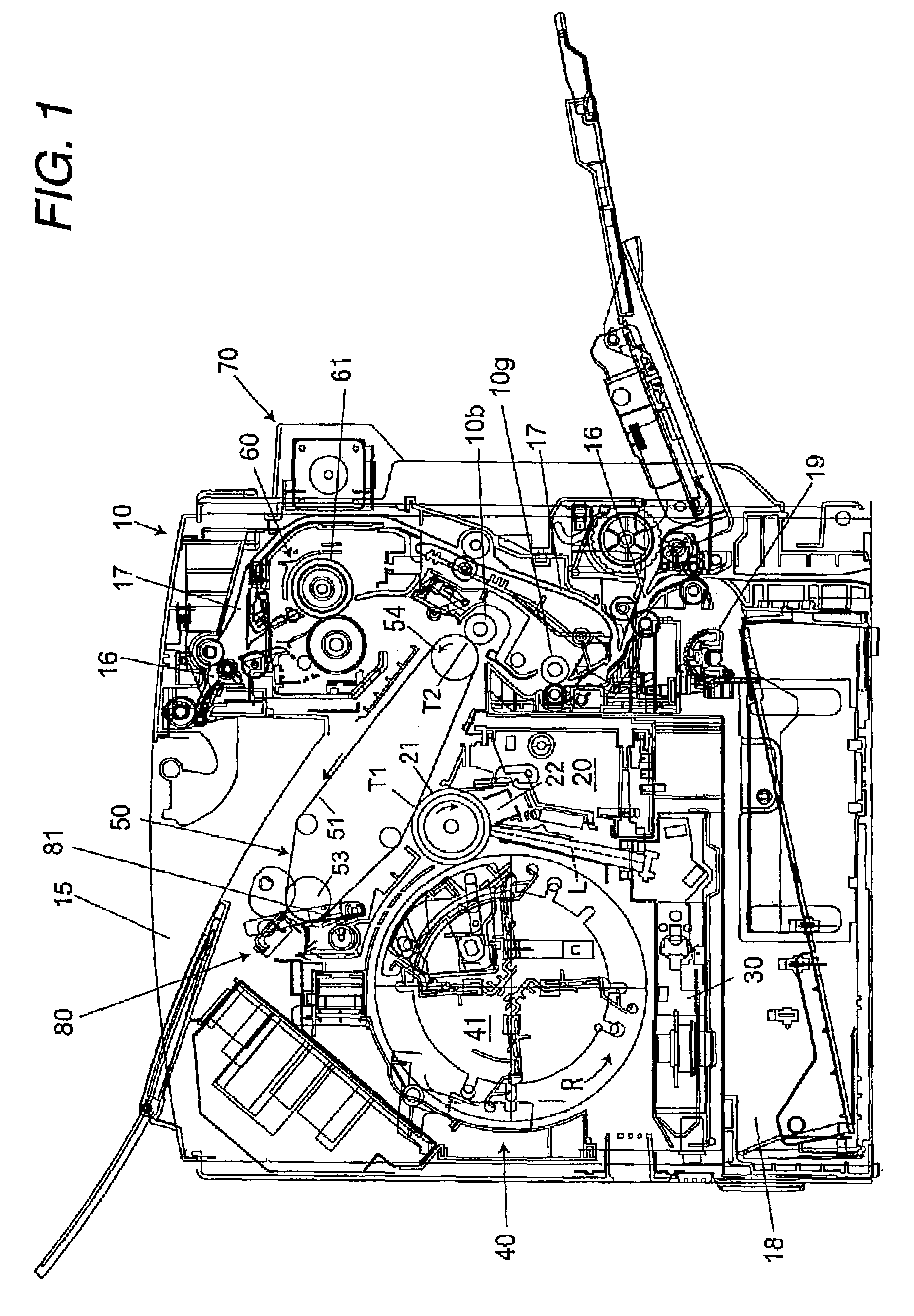

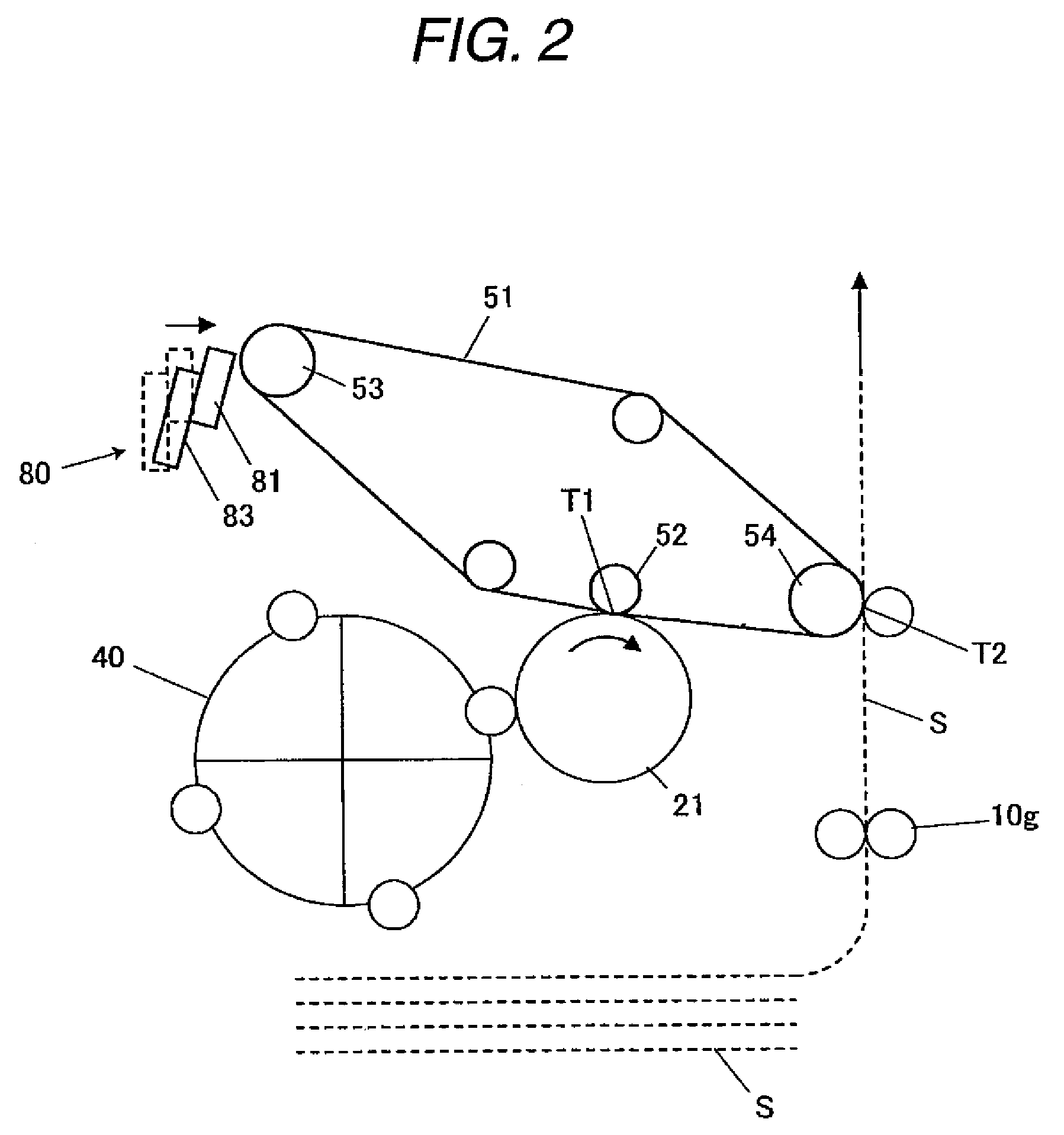

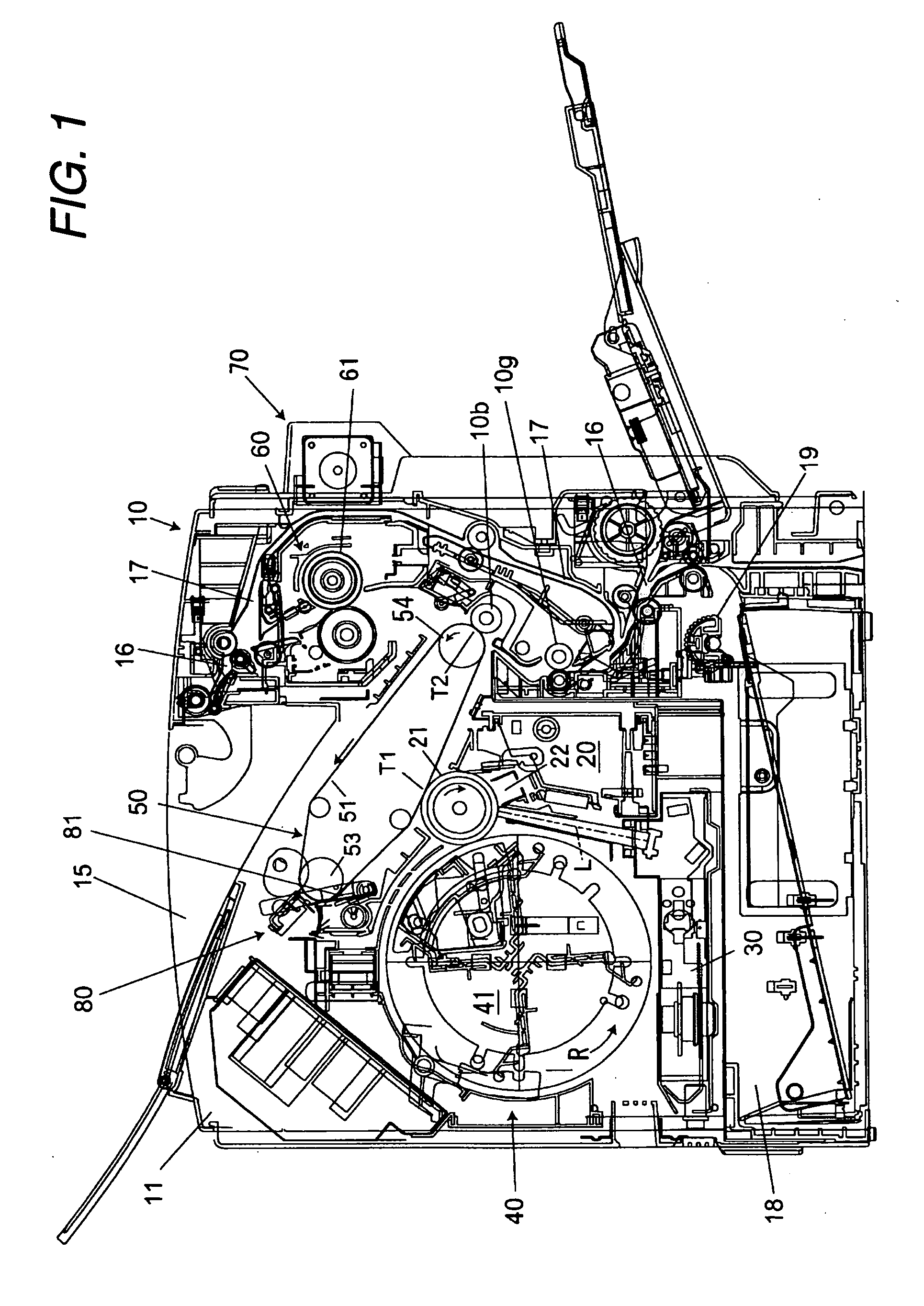

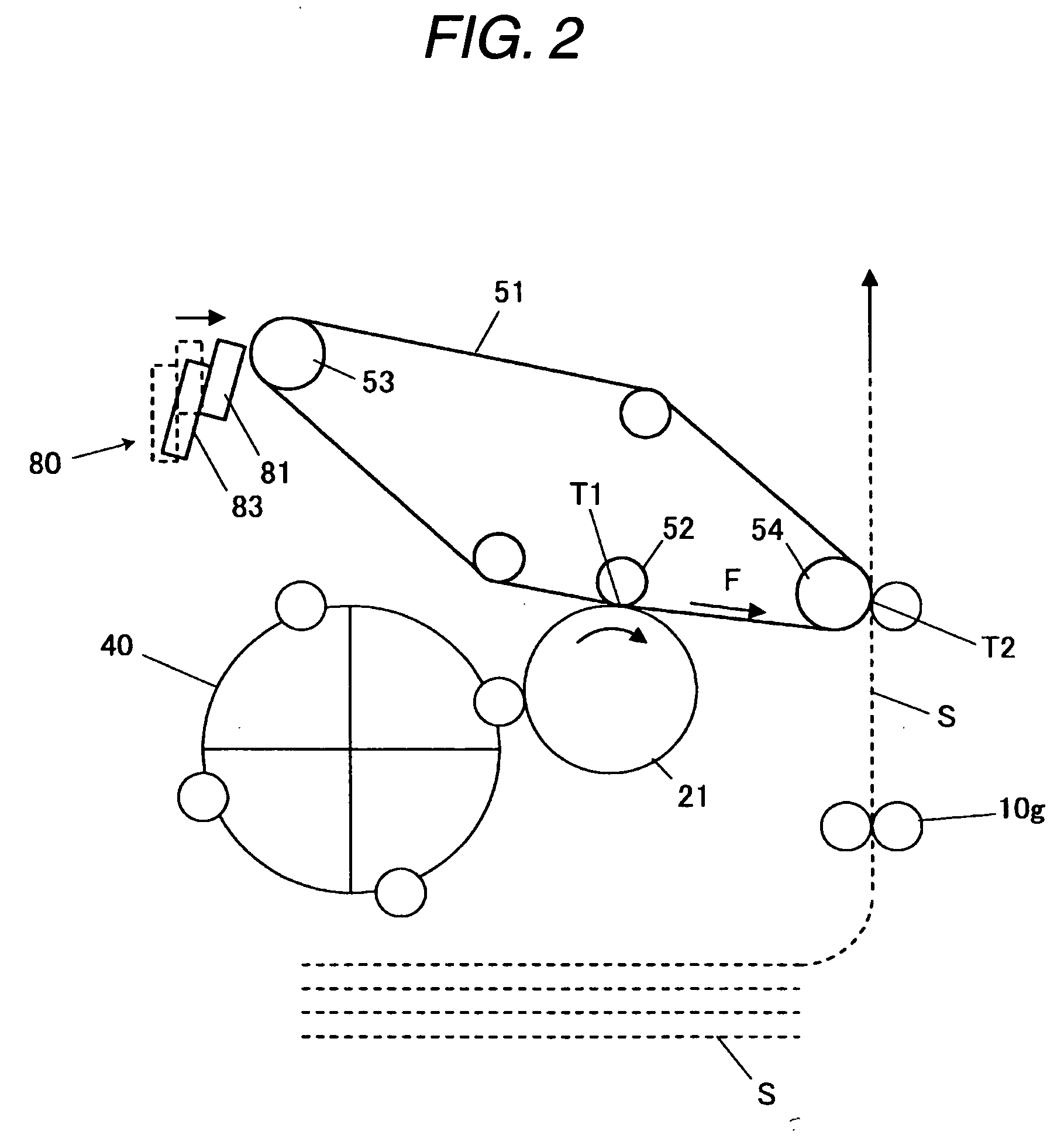

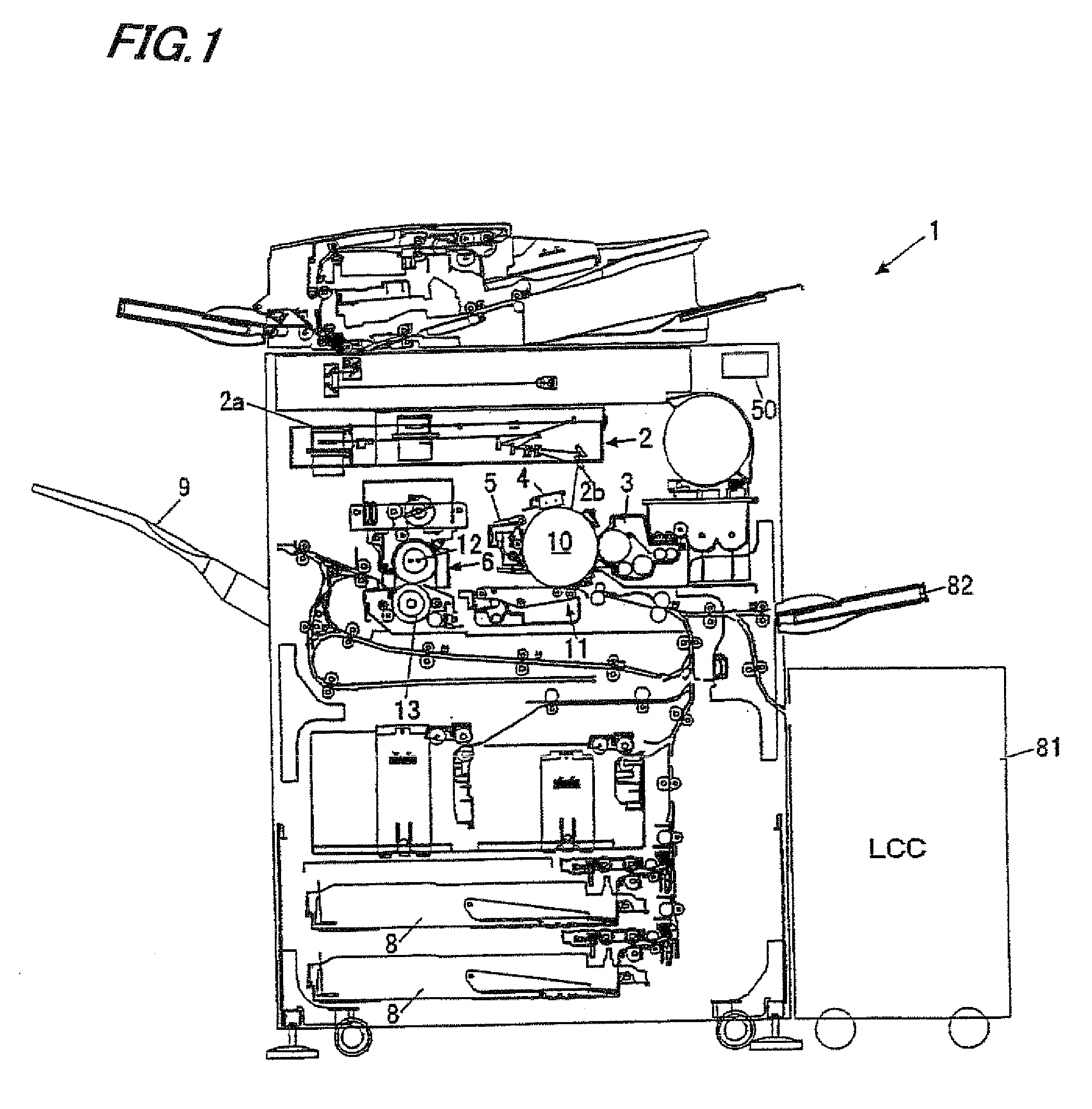

Image forming apparatus with controlled timing of contact of cleaning blade against intermediate transfer member

InactiveUS7310487B2Reduce the numberPrevent deviationElectrographic process apparatusImage formationRecording media

Owner:SEIKO EPSON CORP

Image forming apparatus

InactiveUS20060120771A1Reduce the numberPrevent deviationElectrographic process apparatusImage formationRecording media

Owner:SEIKO EPSON CORP

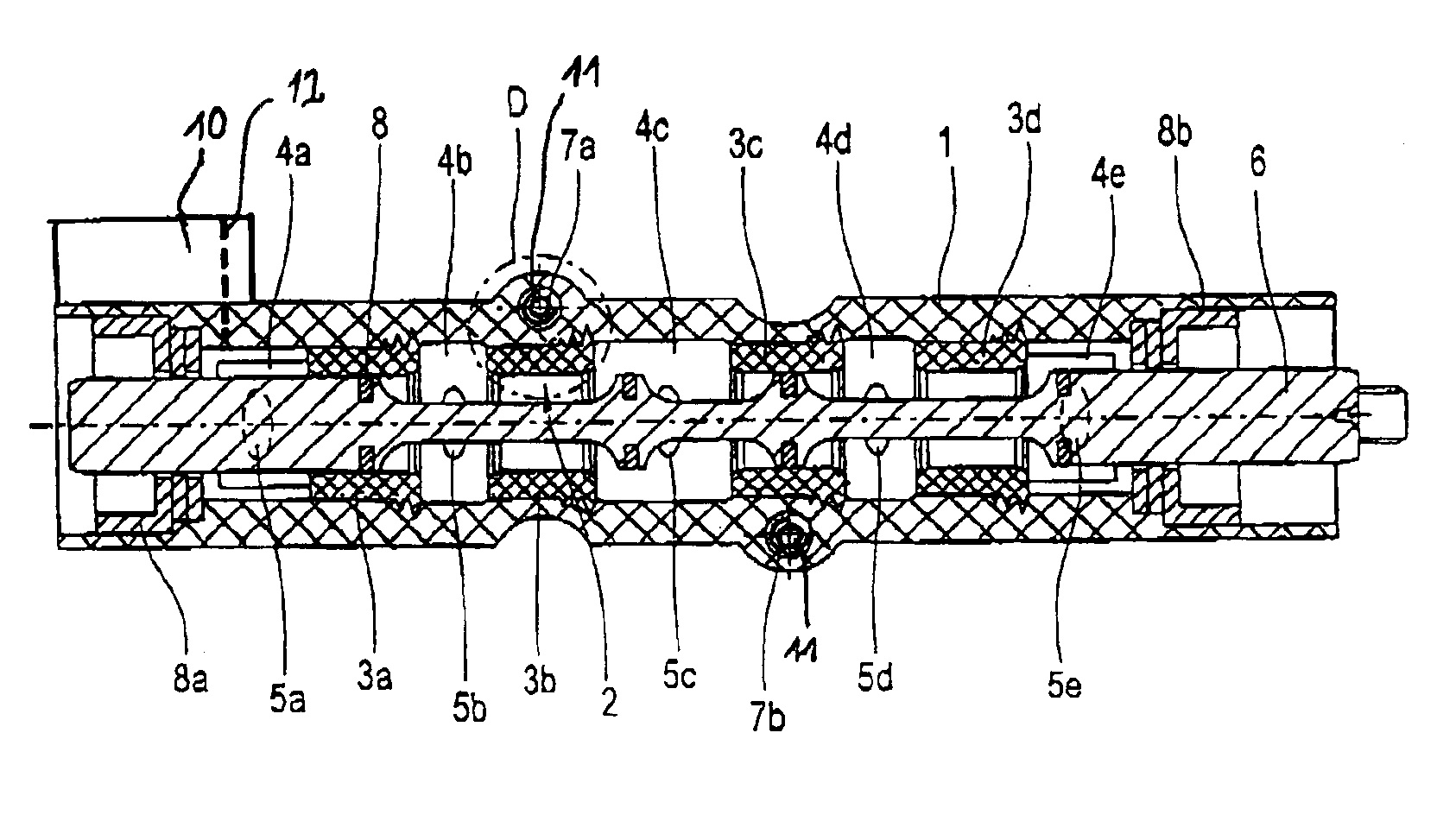

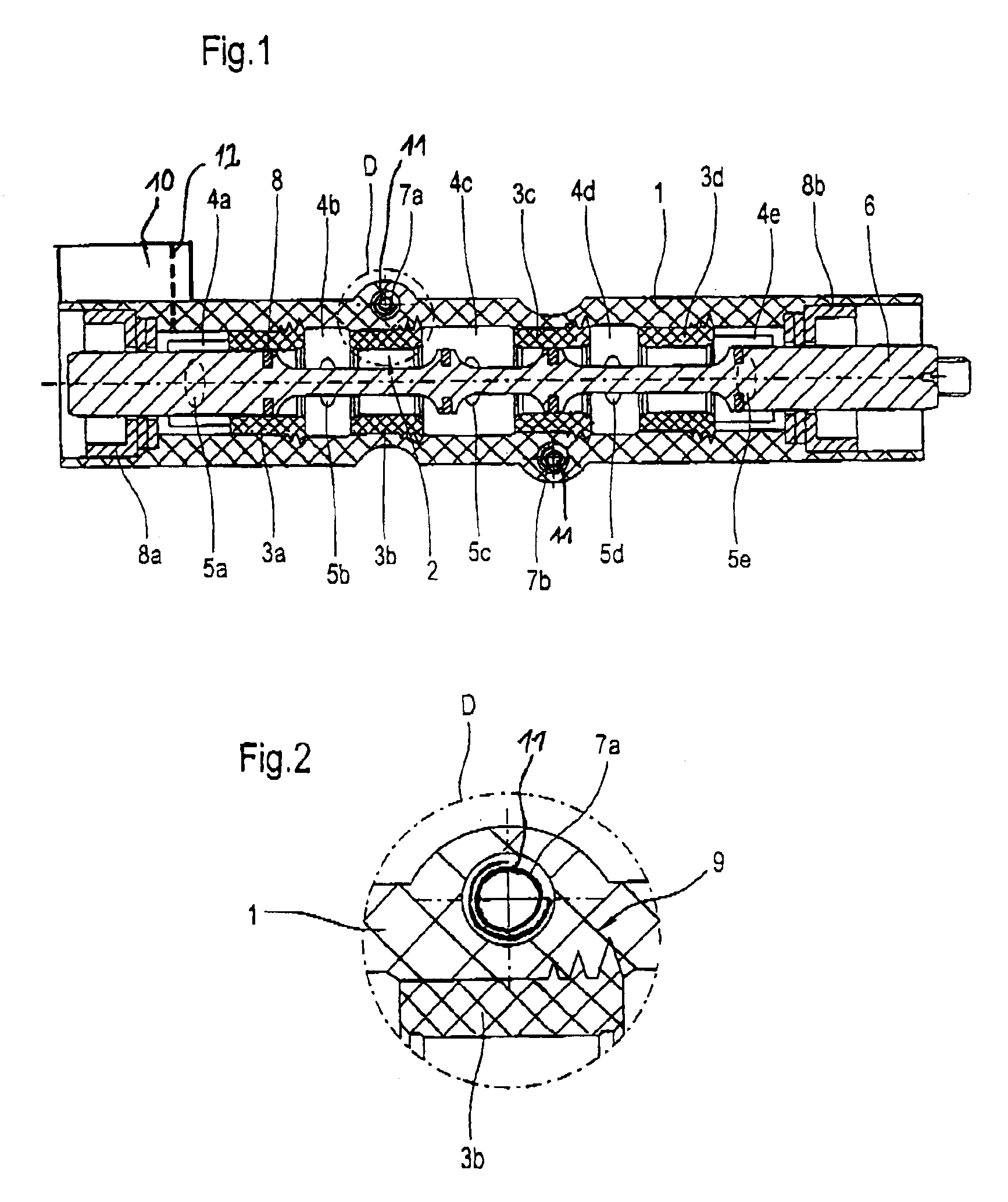

Pneumatic gate valve with an injection-molded valve housing

InactiveUS6953055B2Rule out the possibilityReduce material thicknessServomotor componentsMultiple way valvesFluid compartmentsPlastic materials

A pneumatic gate valve includes a valve housing made of injection-molded plastic material and having a plurality of external ports. Received in the valve housing are a plurality of valve bushings disposed in axial-spaced relationship as to define a valve bore and a plurality of pressure fluid compartments in fluid communication with the ports. A slide member for regulating a flow of compressed air between the ports is accommodated in the valve bore of the valve housing and displaceable in axial direction. The valve bushings are made of plastic material with a same melting temperature as the plastic material of the valve housing so as to realize a material union between the valve bushings and the valve housing, when plastic material is molded around the valve bushings during injection molding of the valve housing.

Owner:BOSCH REXROTH AG

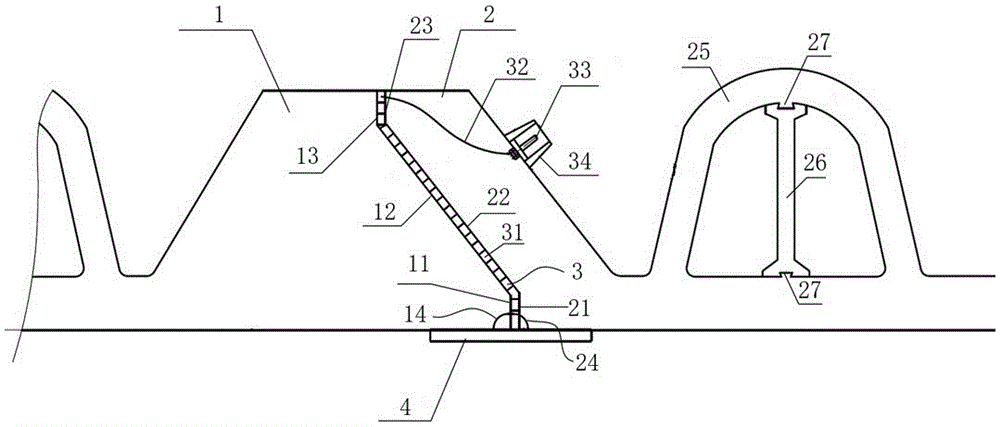

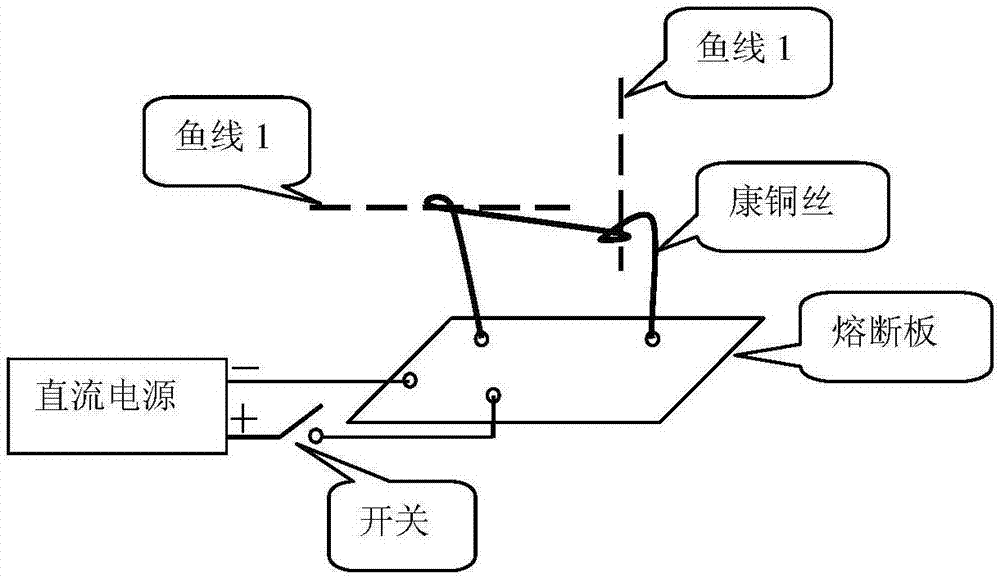

Deployment device and method of spatial mechanism

InactiveCN107972893ASave installation spaceLow costCosmonautic vehiclesCosmonautic power supply systemsAerospace engineeringFishing line

The invention relates to a deployment device and method of a spatial mechanism and belongs to the technical field of spatial mechanism deployment of in-orbit air vehicles. For an in-orbit air vehicleespecially a miniature air vehicle provided with a deployment mechanism such as a solar panel substrate, the solar panel substrate is deployed through traditional explosive bolts, multiple defects exist, in order to solve the problem, a mode for fixing the solar panel substrate through constantan wires and fish wires is proposed, power is supplied to the constantan wires through a fusing device, the constantan wires generate heat to fuse the fish wires, the deployment mechanism such as the solar panel substrate is released and deployed, and by the adoption of the novel deployment mode, an installation space is small, cost is relatively low, and impact on an air vehicle body is quite small.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

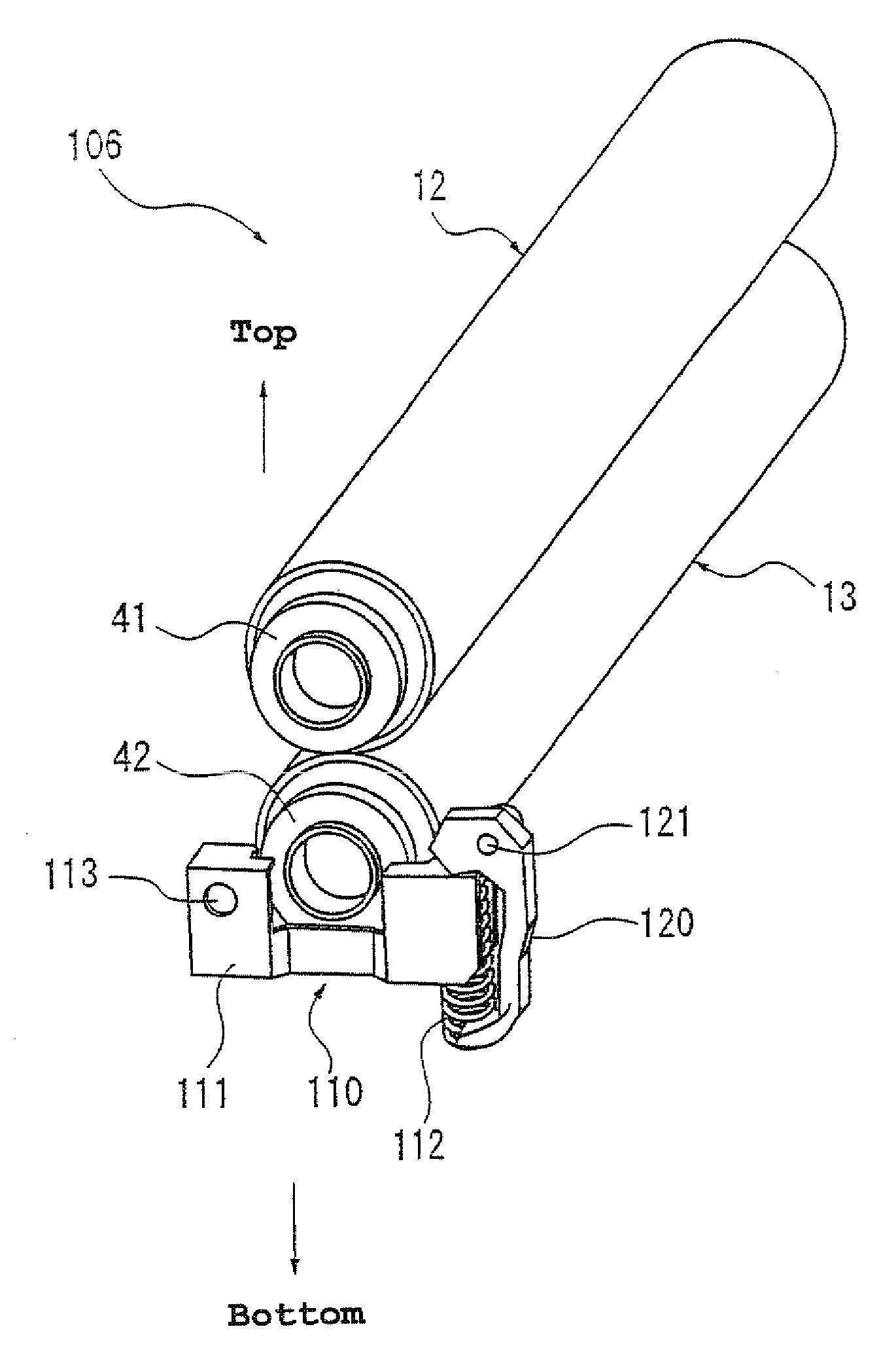

Fusing device and image forming apparatus using the same

InactiveUS20090208266A1Avoid it happening againStable fusing operationElectrographic process apparatusEngineeringImaging equipment

A fusing unit is comprised of a fusing roller and a pressing roller, having an elastic layer on their outer peripheral surface and a pressing structure for pressing the fusing roller against the pressing roller, and causes a sheet of paper with an unfixed toner image to pass through the nip portion where the fusing roller and pressing roller are put in press-contact with each other so as to fuse the toner image and fix it to the paper. This fusing unit further includes a pressure release lever for regulating the pressing action of the pressing structure when the rollers are put in press-contact with each other by the pressing structure.

Owner:SHARP KK

Medical high frequency surgical instrument including pivotable electrode support

ActiveCN104271061BAvoid damageReliable fusionSurgical instruments for heatingSurgical forcepsSurgical departmentSurgical device

The present invention proposes a manually operable HF instrument in a bipolar configuration, said manually operable HF instrument comprising: a jaw portion consisting of two electrode legs that can face each other like clippers or scissors and an instrument handle for operating and activating the jaw portion. A separate electrode mount is hinged to at least one electrode leg of the jaw portion so as to be pivotable relative to the electrode leg, the electrode in turn being resiliently / compliantly mounted on the electrode mount.

Owner:AESCULAP AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com