Narrow-gap MAG/MIG automatic horizontal position welding device and method based on welding wire plastic deformation

A technology of plastic deformation and narrow gap, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of large welding residual stress and residual deformation, high labor intensity of welding operators, complex hardware and software systems, etc. Welding residual stress and residual deformation, uniform fusion, reliable, more controllable and stable, and the effect of improving welding productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

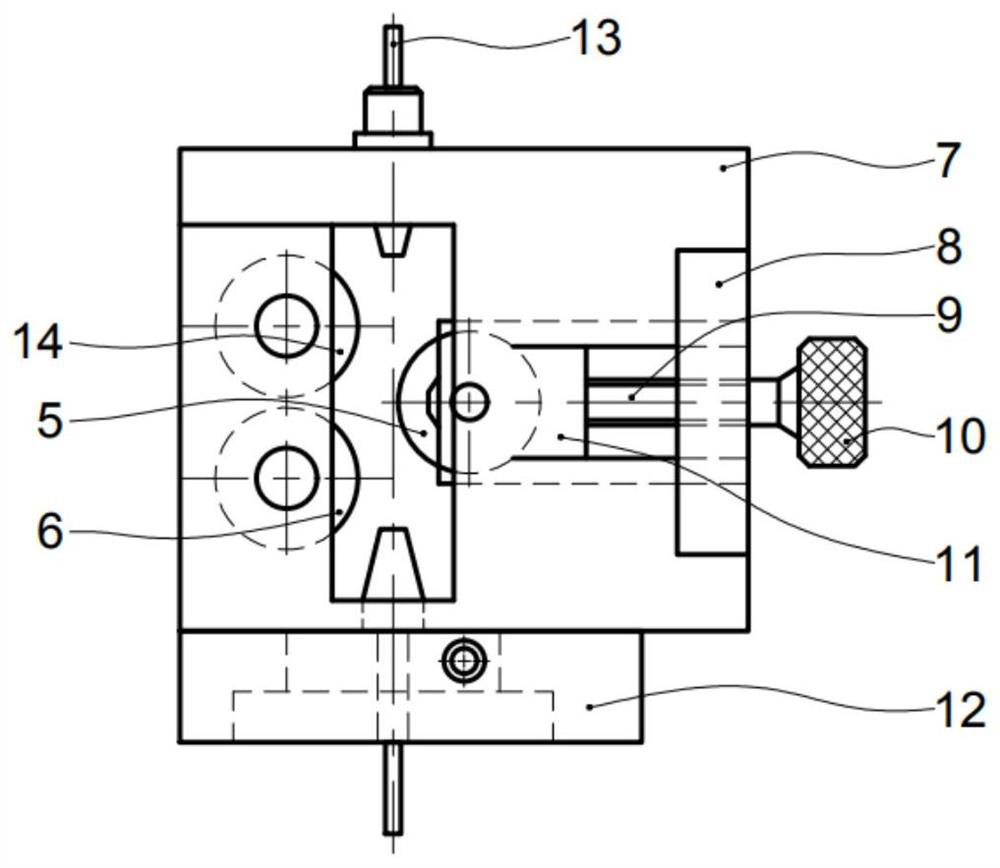

[0033] Such as Figure 1-4As shown, the wire straightening mechanism that can rotate along the circumference of the welding wire consists of a wire straightening mechanism body 7, a first fulcrum roller 6, a second fulcrum roller 14, a wire straightening roller 5, a wire straightening roller seat 11, a screw 9, Nut seat 8, knob 10, and swivel seat 12 form. The center of rotation of the first fulcrum roller 6 and the second fulcrum roller 14 is parallel to the axis of the welding wire 13, and the center distance between the two fulcrum rollers is greater than the diameter of a fulcrum roller; One-half of the center distance. The upper and lower sides of the straightening roller seat 11 are processed into boss-shaped guide rails, and the corresponding positions where the straightening roller seat 11 is installed in the straightening mechanism body 7 are processed into guide rail grooves, and the straightening roller seat 11 is pushed by the rear screw 9 Next, the wire straight...

Embodiment 2

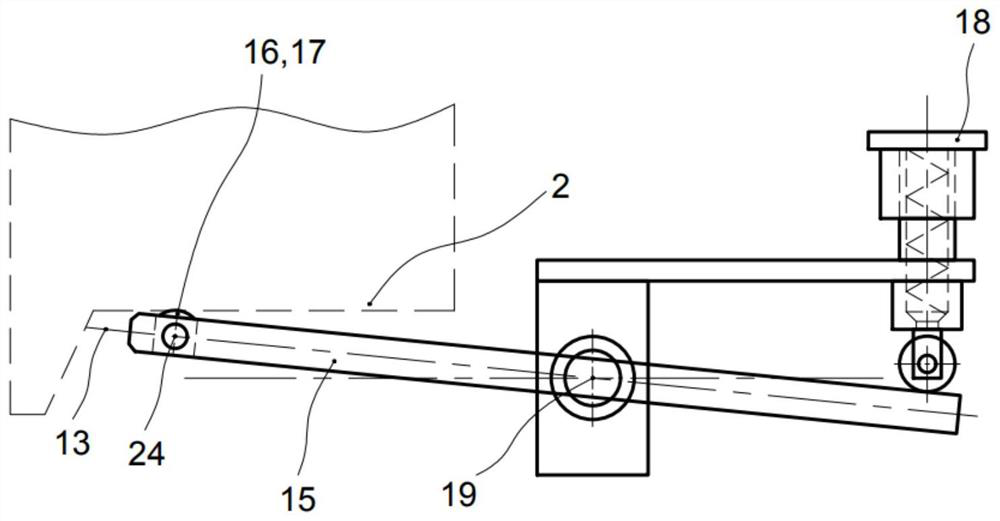

[0039] Such as Figure 5-6 As shown, embodiment 2 is the method for applying the automatic horizontal welding device in embodiment 1 to carry out automatic horizontal welding, which specifically includes the following steps:

[0040] S1. Respectively deflect the front plate type narrow gap MAG / MIG welding torch and the rear plate type narrow gap MAG / MIG welding torch to make it into a scissors shape;

[0041] S2. The cladding method of two layers per layer is adopted; the arc of the front pass acts on the sharp corner of the lower wall of the groove of the weldment, and the arc of the rear pass acts on the sharp corner of the upper wall of the groove of the weldment;

[0042] S3. After the molten pool of the front bead is solidified, the rear weld bead is welded when it is still in the high temperature range of 700°C to 800°C; with the backward tilting method, the arc acts on the fusion zone in front of the molten pool;

[0043] S4. The front plate type narrow gap MAG / MIG wel...

Embodiment 3

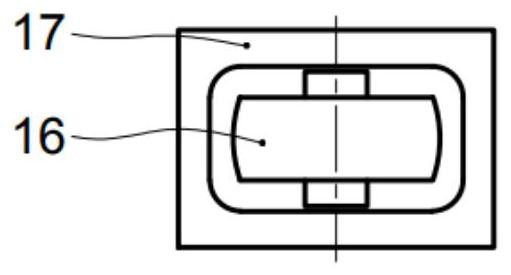

[0048] In Example 3, the master roll 16 is made of alumina ceramics, with a total thickness of 8 mm, a roll diameter of 6 mm, and a roll shaft diameter of 3 mm. Other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com