A low heat input narrow gap vertical gas-electric vertical welding method

A technology of vertical gas-electric vertical welding and narrow gap, which is applied in the direction of arc welding equipment, welding equipment, welding medium, etc., can solve the problems of large heat input and poor penetration of side walls, etc., and achieve the reduction of weld filling area and ensure Penetration effect, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

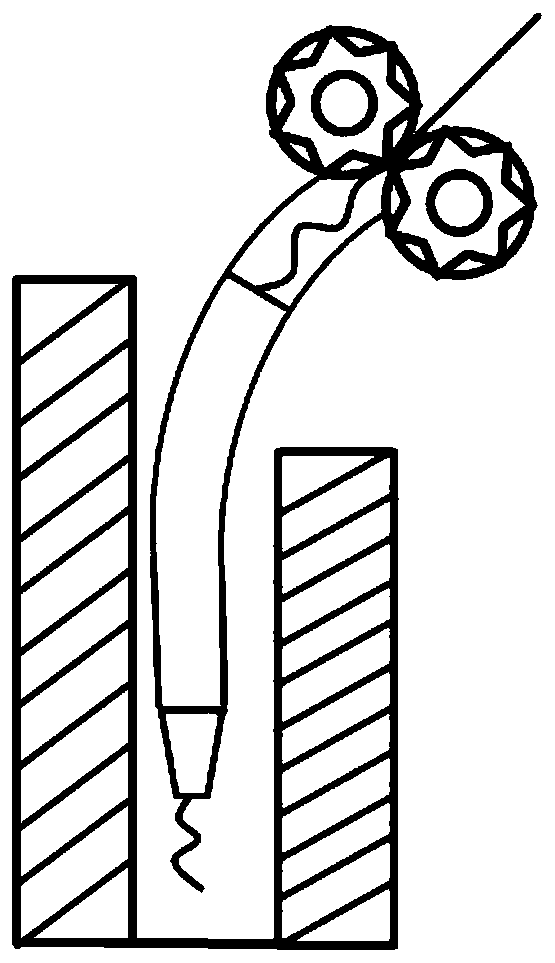

Method used

Image

Examples

Embodiment 1

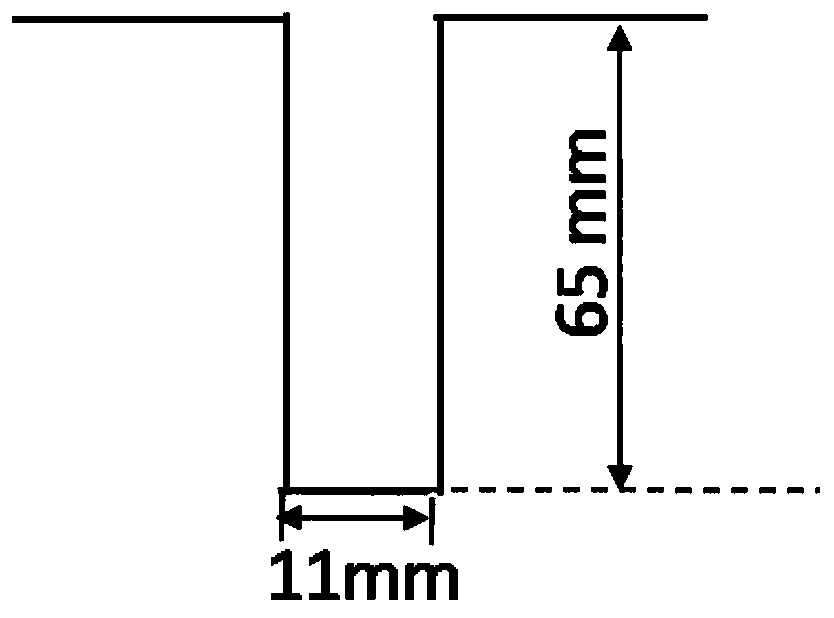

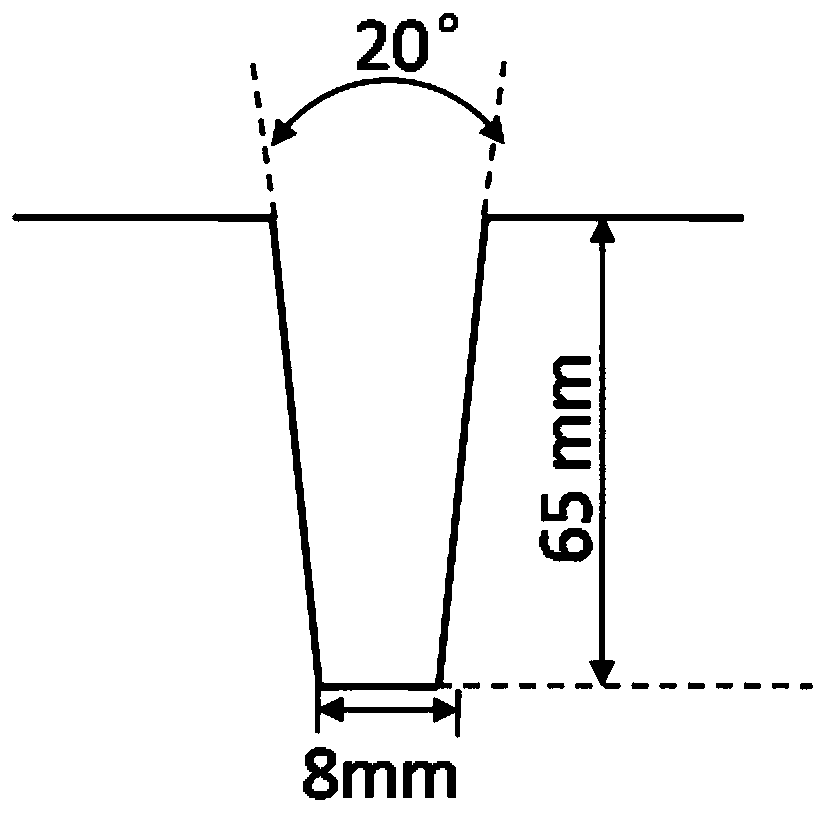

[0022] Prepare the welding test plate EH36, label A, the plate thickness is 65mm, the length is 1000mm, no groove is required, and the root gap is 11mm. According to the formula Q=0.8h+20*(d-10) fitted according to the new process, it can be calculated The output heat input is about 72kJ / cm, and the appropriate welding current, voltage and welding speed are deduced from the calculated heat input, as shown in Table 1.

[0023] Table 1 Embodiment 1 Welding process parameters

[0024]

Embodiment 2

[0033] Prepare the welding test plate EQ47, label C, the plate thickness is 140mm, the length is 1200mm, there is no need to open the groove, and the root gap is 12mm. According to the formula Q=0.8h+20*(d-10) fitted according to the new process, it can be calculated The output heat input is about 152kJ / cm, and the appropriate welding current, voltage and welding speed are deduced from the calculated heat input, as shown in Table 4.

[0034] Table 4 embodiment 2 welding process parameters

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com