A stainless steel composite nickel material welding process

A welding process and stainless steel technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of reducing production costs, reducing the amount of welding materials, and reducing the metal filling area of the basic welding seam, so as to reduce the production cost, reduce The amount of welding material and the effect of ensuring corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

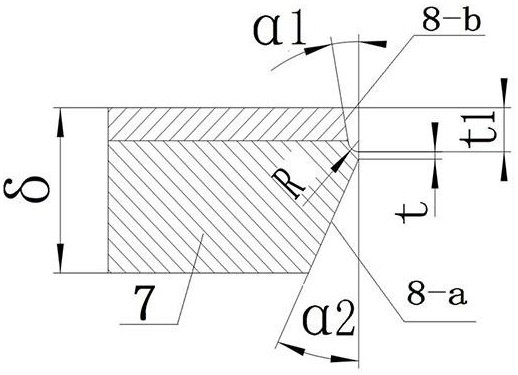

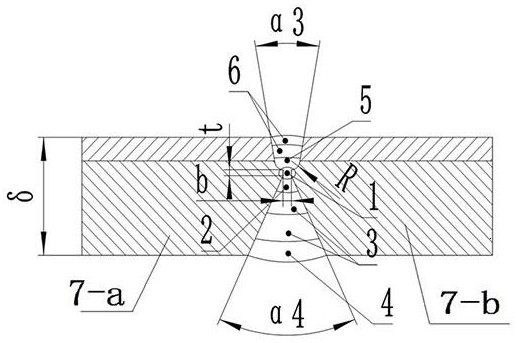

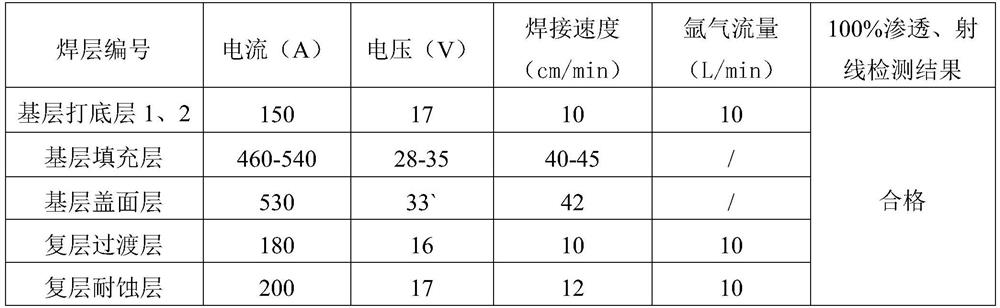

[0030] A stainless steel composite nickel material welding process, the material is S30409+NO2201, and the thickness δ is 32+8mm. Firstly, the rust and other impurities and dirt within 20mm of the welding end of the base metal 7 are thoroughly cleaned, and then the base metal 7 is welded by numerical control processing equipment. The welding end is treated as groove 8, the blunt side t is 1mm, the outer groove is V-shaped, the single-side groove angle 8-a is 25°, the inner groove is J-shaped, and the single-side groove angle is 8 -b is 10°, the transition arc radius R is 3mm, and the groove depth t1 is 12mm. The specific structure is shown in Figure 1. After the groove is processed, the pairing is carried out. The gap b between the two grooves is 3-4mm. For the specific structure, see figure 2 ; Then carry out base weld seam welding, using The argon arc welding process makes the bottom layer 1 and 2 of the base weld seam for bottom welding, the welding current is 100-160A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com