Welding method for U-shaped ribs of orthotropic plate of bridge girder

A welding method and orthotropic bridge technology, which are applied in welding equipment, arc welding equipment, workpiece edge parts, etc., can solve the problem of reducing the amount of weld metal filling, increasing the size of the blunt edge of the groove, and reducing the amount of groove processing. and other problems, to achieve the effect of reducing the amount of weld metal filling, reducing the filling area, and reducing the amount of groove processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

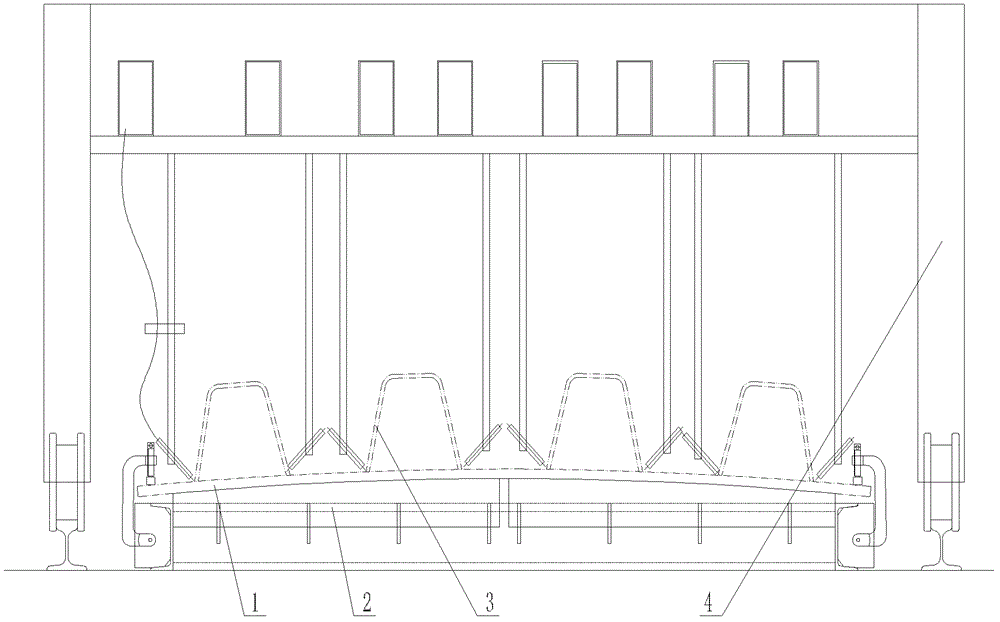

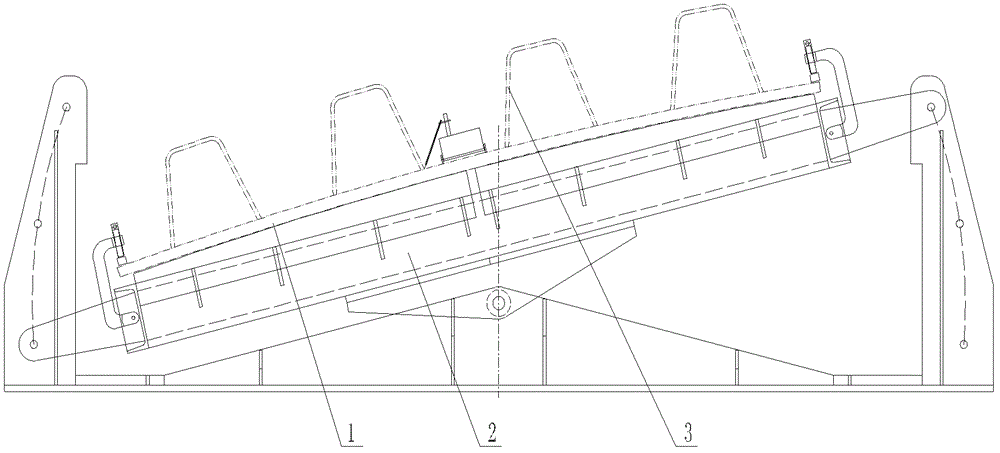

[0027] Attached below figure 1 , 3 , 4 describe the first embodiment of the present invention.

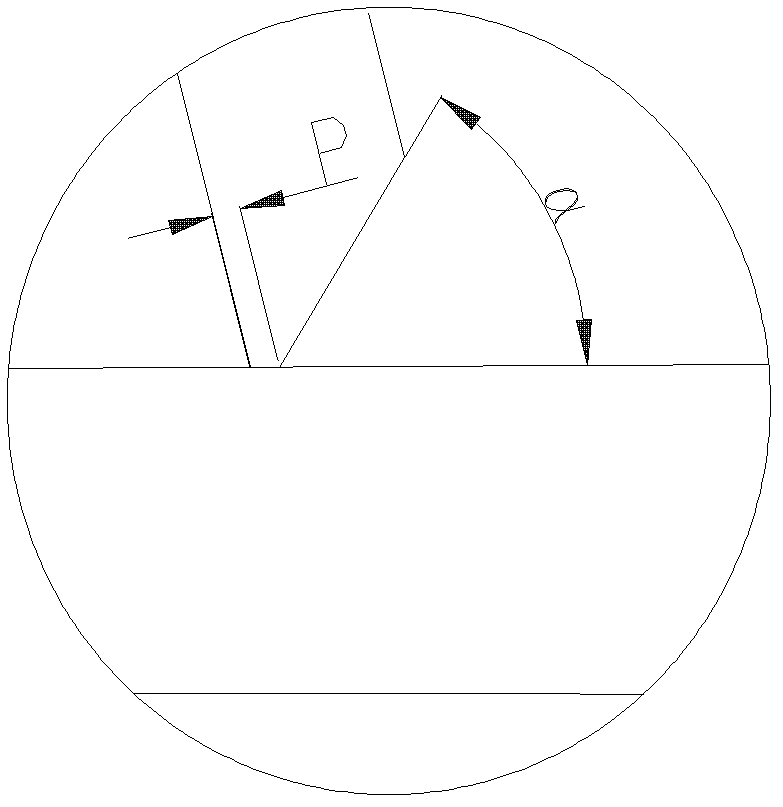

[0028] 1) Make a bevel on the outside of the 6mm U-shaped rib 3, the blunt side P is 1.5mm, and the bevel angle α is 50°;

[0029] 2) Arrange the U-shaped ribs 3 longitudinally on the bridge deck 1 according to the designed position and position them by spot welding;

[0030] 3) Fix the bridge deck 1 with a yield strength of 345MPa to 390Mpa on the anti-deformation tire frame 2, and the anti-deformation angle is 0.4°;

[0031] 4) Set the horizontal multi-head door-type automatic welding machine 4 above the anti-deformation tire frame 2, so that the bridge deck 1 is located at the welding station of the horizontal multi-head door-type automatic welding machine 4, and then use the horizontal position welding method to weld the U-shaped The rib 3 is welded on the bridge deck 1 by one long piece. The welding adopts a solid welding wire argon-rich gas shielded welding process. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com