Connecting method of MgB* superconduction in strip shape

A connection method and superconducting technology, applied in the direction of connecting contact materials, etc., can solve the problems of inability to properly guarantee the mechanical strength of the joint, high reaction temperature, and inability to connect easily oxidized superconducting cores, etc., so as to improve the critical current characteristics and reduce the joints. resistance, the effect of reducing the influence of the external atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

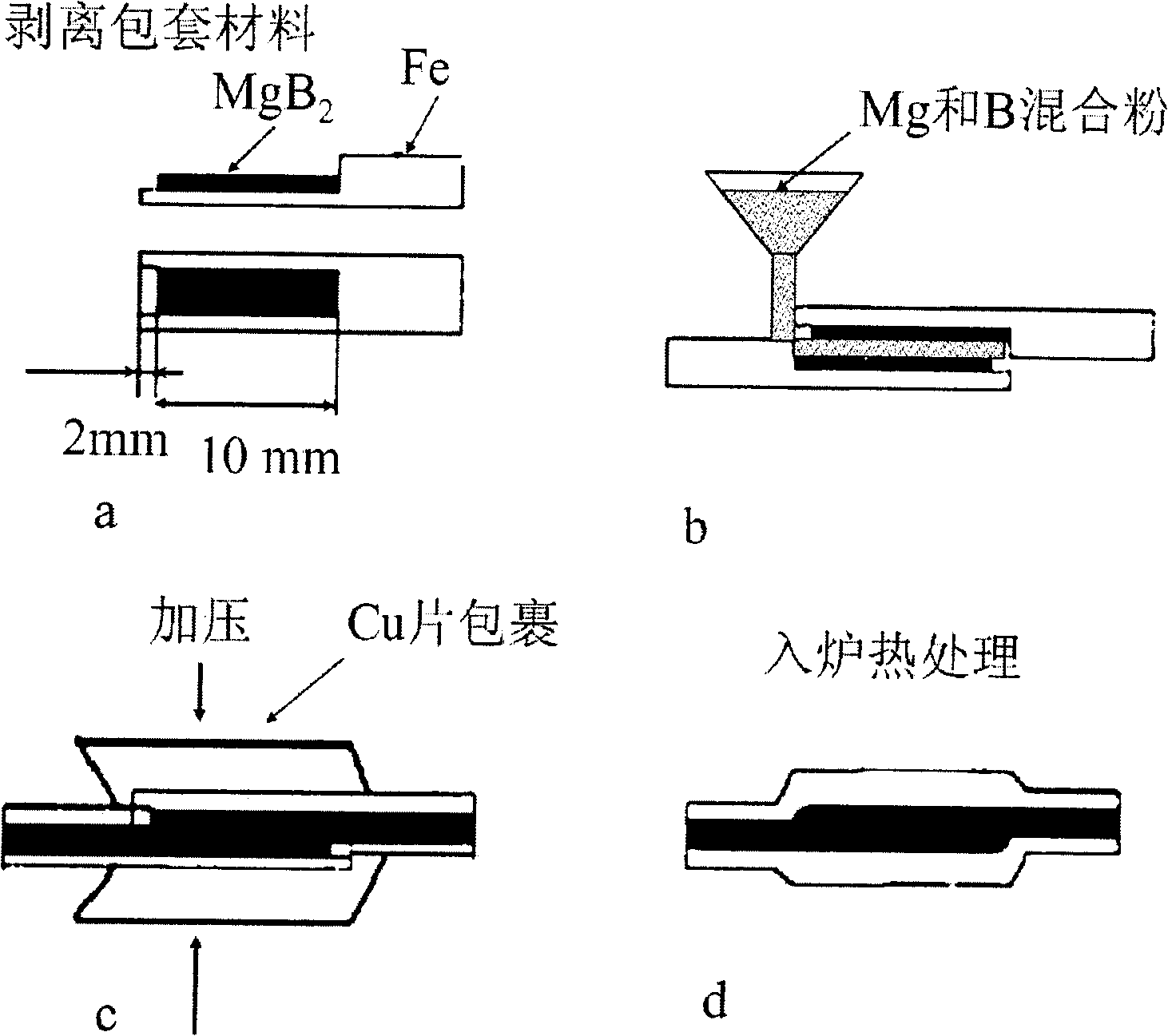

[0015] first as figure 1 As shown in a, peel off the sheath material with a length of about 5-10 mm on one side of the two sections of strip ends to be connected by mechanical means, exposing a superconducting core with a length of about 10 mm, and the strip after removing the sheath material is shown as figure 2 as shown, figure 2 A is a single-core strip, and b is a multi-core strip. Then if figure 1 As shown in b, two sections of strip superconducting cores with cladding materials removed are relatively attached, and a small amount of Mg, which has been mixed and ground according to the atomic ratio Mg:B=1:2, is added between the contact surfaces of the two sections of superconducting cores. B Mix the powder, the particle size of the added powder is 325 mesh, and keep the two strips to be connected in close contact. Then if figure 1 As shown in c, use a thin Cu sheet to tightly wrap the outer side of the connecting part of the superconducting strip, so that the two st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com