Six-column differential-pressure distillation device for extra edible alcohol and process therefor

An edible alcohol and distillation device technology, which is applied in the preparation of alcoholic beverages, the preparation of organic compounds, and the general water supply saving, etc., can solve the problems that alcohol impurities cannot be further eliminated, special-grade edible alcohol cannot be used, and production is unstable. Conducive to the removal of impurities, easy control of working conditions, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

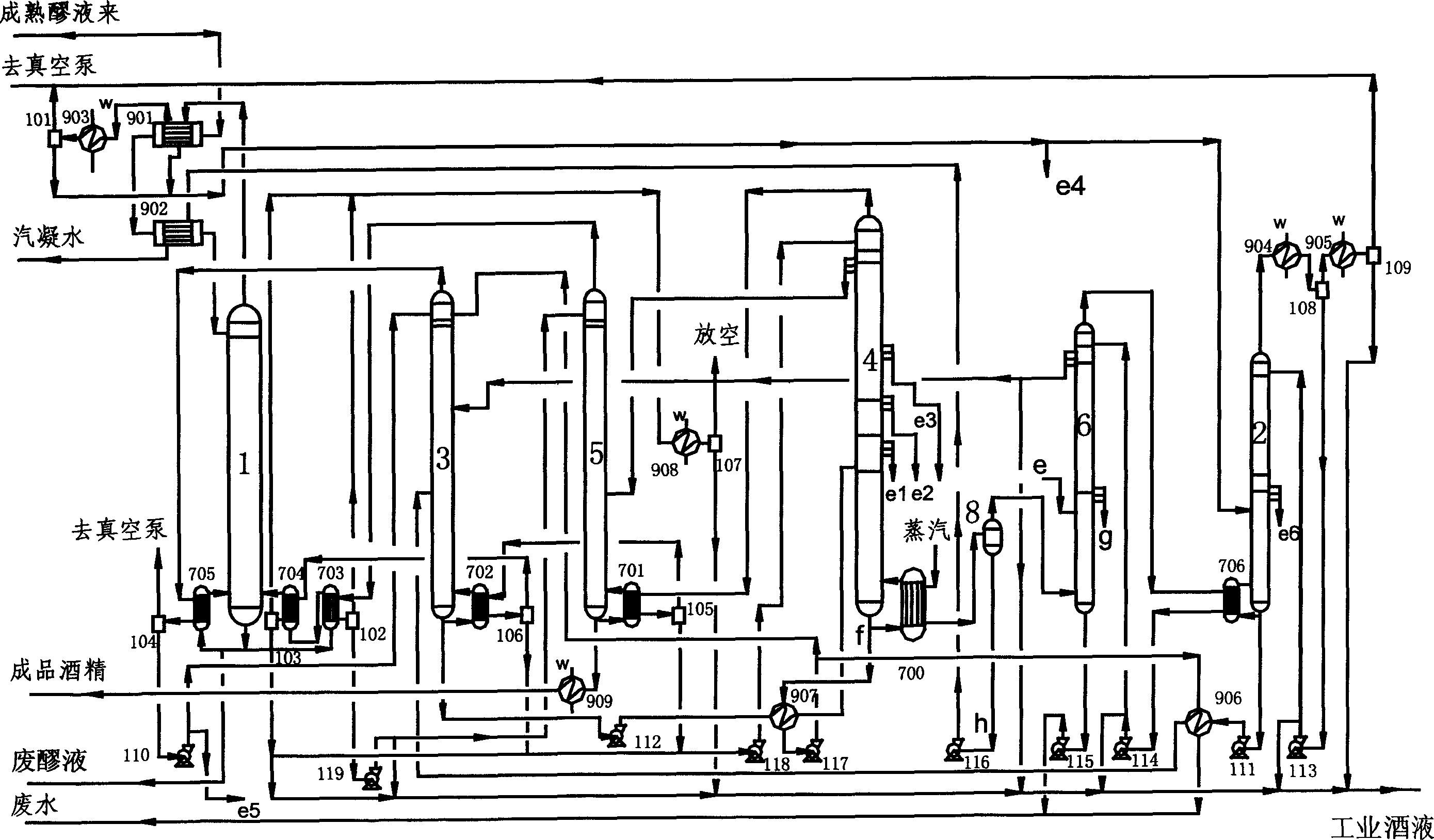

[0030] Example: such as figure 1As shown, the special-grade edible alcohol six-tower differential pressure distillation device includes crude distillation tower 1, vacuum dealdehyde tower 2, water washing tower 3, rectification tower 4, methanol tower 5 and recovery tower 6, and the top of rectification tower 1 passes through pipelines The shell side of the methanol tower reboiler 701 communicates with the fifth vapor-liquid separator 105, and the top of the fifth vapor-liquid separator 105 passes through a pipeline through the water washing tower. The shell side of the reboiler 702 communicates with the sixth vapor-liquid separator 106, and the sixth vapor-liquid separator The top of the liquid separator 106 is communicated with the third vapor-liquid separator 103 through a pipeline through the shell side of the second reboiler 704 of the crude distillation tower, and the third vapor-liquid separator 103 is vented through a pipeline through the tube side of the final condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com