Cast-in-situ continuous beam construction method for special railway line stands

A technology for passenger dedicated lines and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of cumbersome process operation, high material consumption, small working space, etc., and achieves simple process operation, low labor intensity, and construction. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The construction method of cast-in-situ continuous beams covered with supports for railway passenger dedicated lines includes the following steps:

[0022] (1) Foundation treatment: Excavate the surface backfill and humus soil within the scope of the support foundation, replace and fill with sand and pebbles in layers with a thickness of 1.5m (the density reaches more than 96%), and pour C20 concrete on it;

[0023] (2) Formwork project: the formwork is made of bamboo plywood, the vertical ribs of the formwork are 10×10cm square wood, the spacing is 15cm (clear distance 5cm), the panel is δ=15mm bamboo plywood, and the transverse back ribs are 2[8 channel steel, per square meter 1 tie rod is arranged, and the tie rod is round steel;

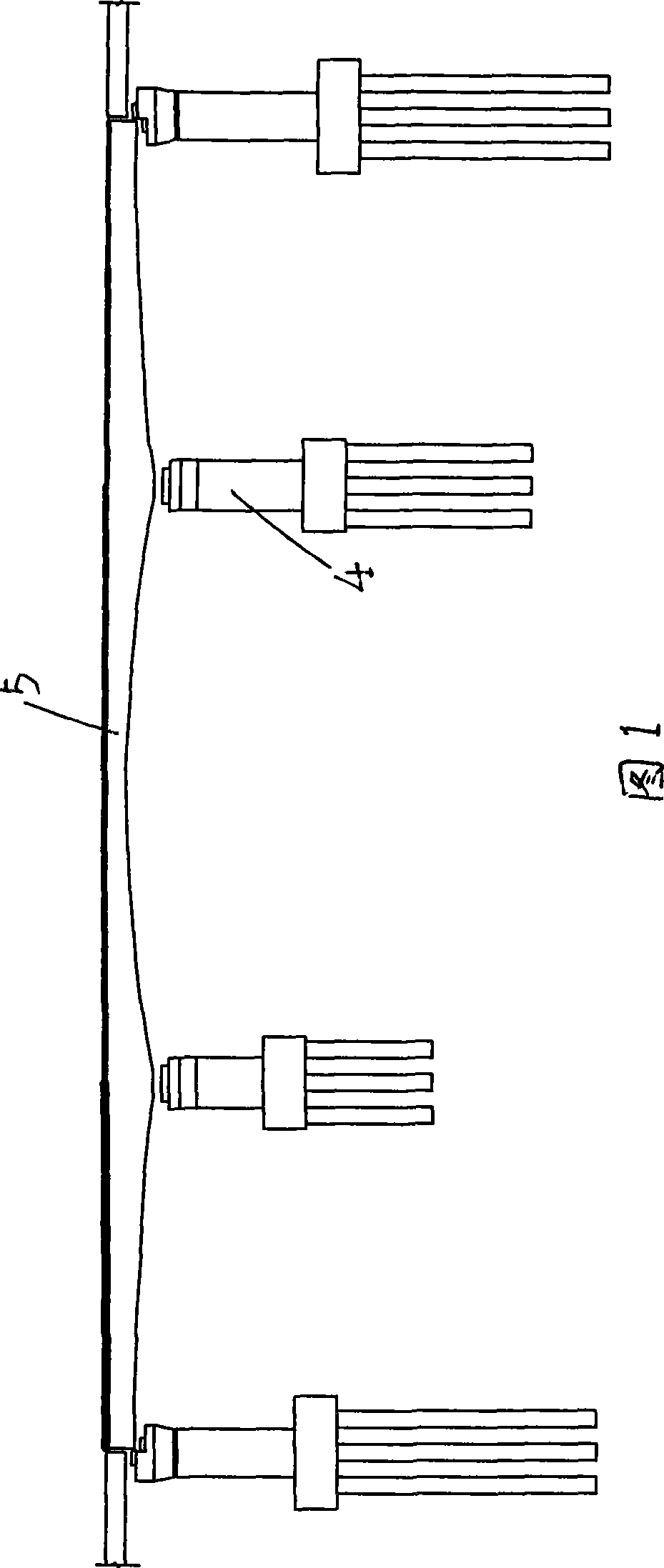

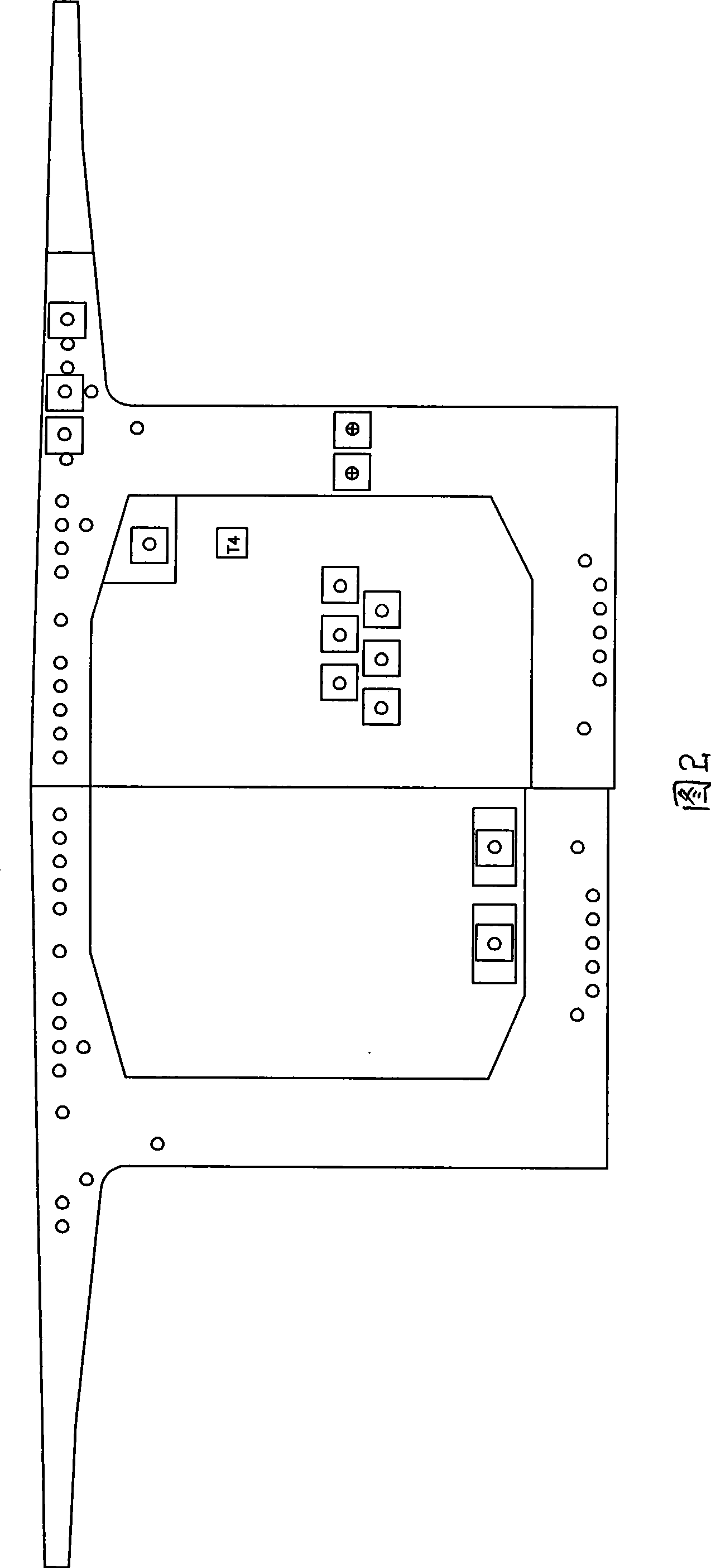

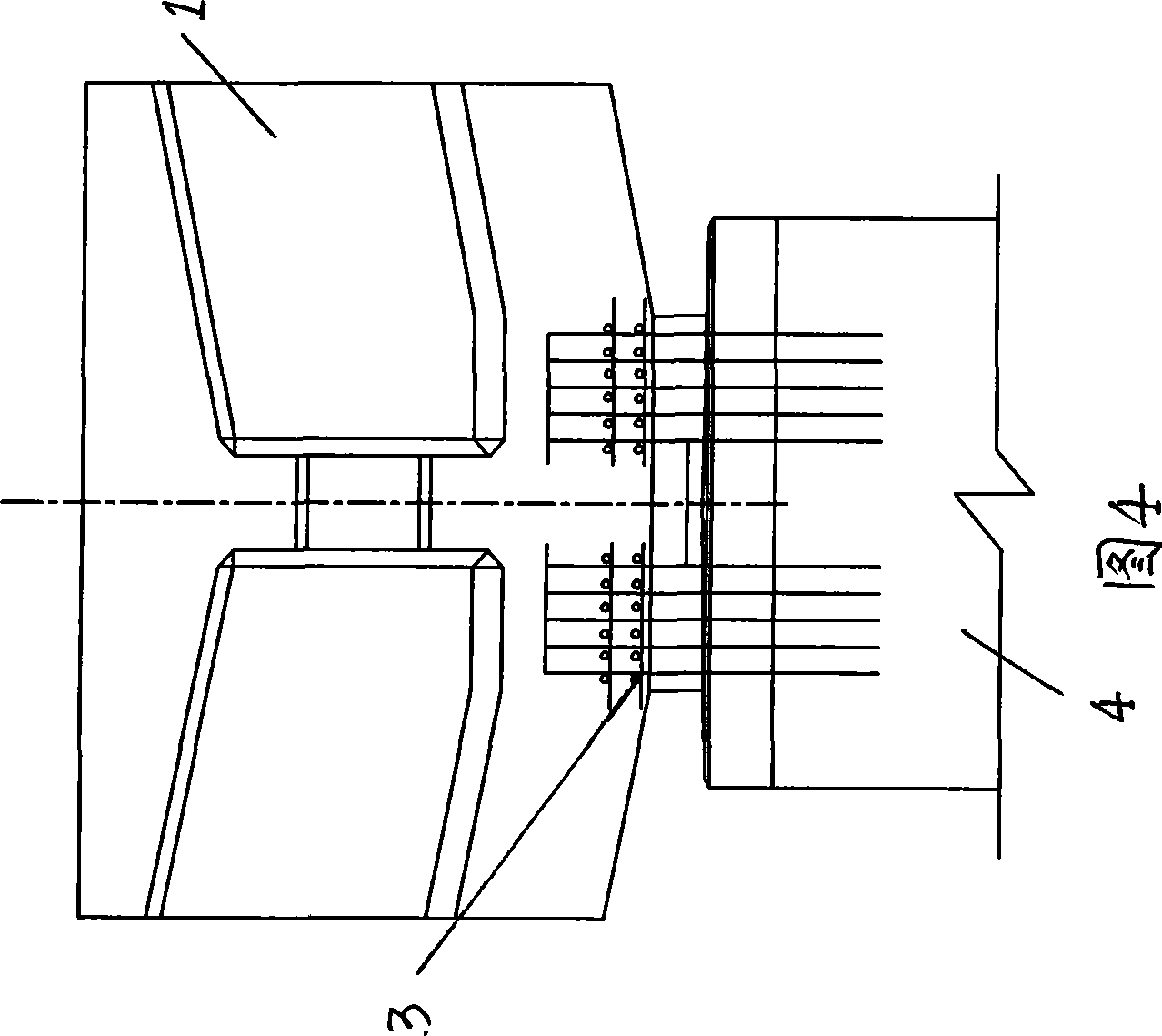

[0024] (3) Cast-in-place support: Bowl-buckle-type full-covered scaffolding is used as the support for cast-in-place beams. Bowl-buckle multifunctional scaffolding is an advanced socket-type steel pipe scaffolding, which has multiple fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com