A preparation method of a microwave composite dielectric board and the prepared microwave composite dielectric board

A composite medium and composite medium film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. The composition is complex and the dielectric constant cannot be further reduced, so as to achieve the effect of eliminating processing limitations, good isotropy of dielectric properties, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

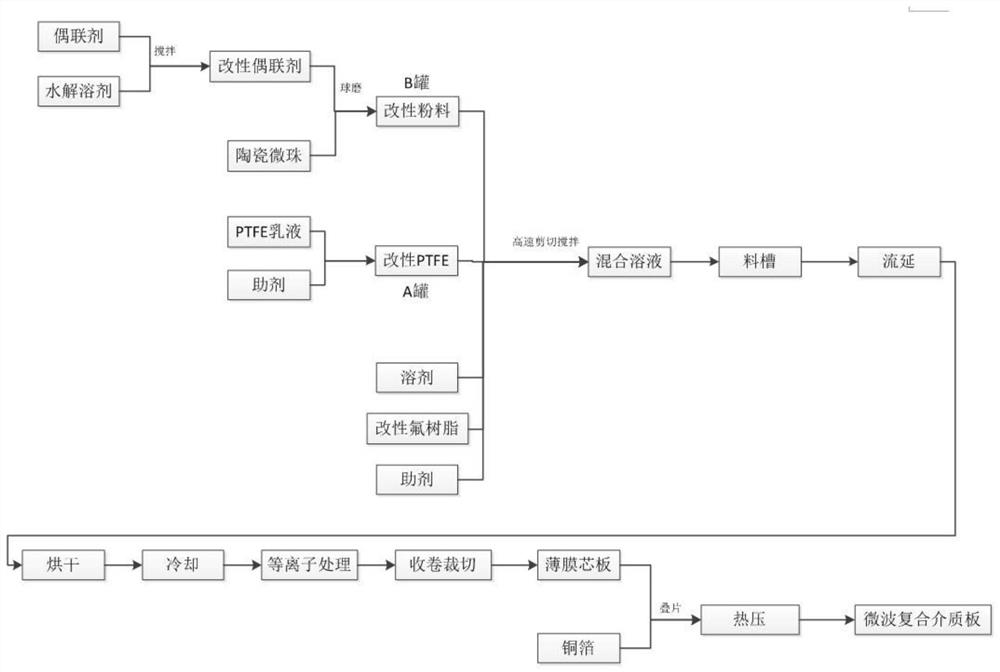

[0032] Such as figure 1 as shown, figure 1 It is a flowchart of the preparation method of the microwave composite dielectric board; the preparation method of the microwave composite dielectric board of the present invention comprises the following steps:

[0033] S1, preparing substrate glue;

[0034] S2, casting: placing the substrate glue prepared in step S1 in a casting machine to obtain a casting film;

[0035] S3, conveying, drying and cooling: the cast film obtained in step S2 is continuously dried through a drying oven, then cooled to room temperature, and the internal stress of the film is eliminated by a tension control mechanism to obtain a microwave composite dielectric film, which is carried out by a winding mechanism. Winding;

[0036] S4, post-processing: performing plasma activation treatment on the microwave composite dielectric film obtained in step S3;

[0037] S5, lamination and lamination: take the microwave composite dielectric film treated in step S4 ...

Embodiment 2

[0065] According to the components specified in Example 2 in Table 1, a low dielectric constant microwave composite dielectric board is prepared, which specifically includes the following steps:

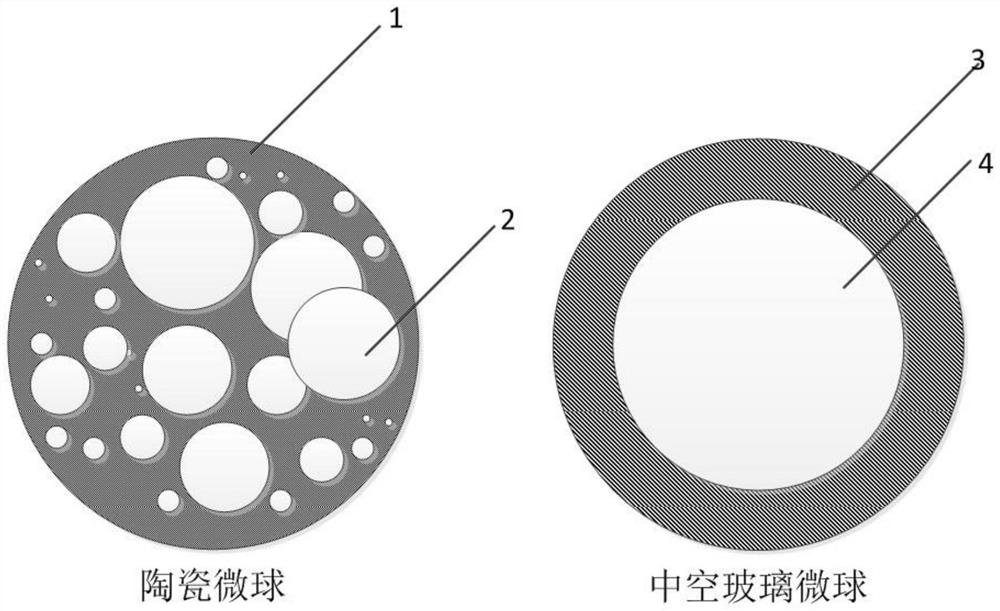

[0066] First add hydrolysis solvent to coupling agent Z-6040, stir evenly, add ceramic microbeads into high-shear stirring tank, stir at 60°C for 1 hour at 100r / min, and transfer to material tank B.

[0067] Add PTFE emulsion and additives into the high-shear stirred tank, stir in the high-shear stirred tank for 1 hour at a speed of 100 r / min, and transfer to material tank A.

[0068] Proportionally, add the modified emulsion, the modified powder, the solvent, the additive, and FEP powder into a 100L high-shear stirring tank in sequence, and stir at 60°C at a speed of 300r / min for 120min , set the vacuum defoaming mode.

[0069] Heat the knife edge of the casting machine to 40°C, transfer the casting film glue to the storage tank of the casting machine, heat the storage tank to 40°C...

Embodiment 3

[0073] According to the components specified in Example 3 in Table 1, a low dielectric constant microwave composite dielectric board is prepared, which specifically includes the following steps:

[0074] First add hydrolysis solvent to the coupling agent Z-6124, stir evenly, add ceramic microbeads to a high-shear stirring tank, stir at 70°C for 1.5h at a speed of 200r / min, and transfer to material tank B.

[0075] Add PTFE emulsion and additives into the high-shear stirred tank, stir in the high-shear stirred tank for 1.5h at a speed of 200r / min, and transfer to material tank A.

[0076] In proportion, add the modified emulsion, the modified powder, the solvent, the additive, and PFA powder into a 100L high-shear stirring tank in sequence, and stir at 70°C at a speed of 400r / min for 75min , set the vacuum defoaming mode. Heat the knife edge of the casting machine to 50°C, transfer the casting film glue to the storage tank of the casting machine, heat the storage tank to 50°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com