Excavation and supporting structure for weak surrounding rock super-large cross-section tunnel and construction method thereof

A technology of super large cross-section and supporting structure, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of slow construction progress, narrow working space, high construction risks, etc., achieve large construction space, simplify demolition process, guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

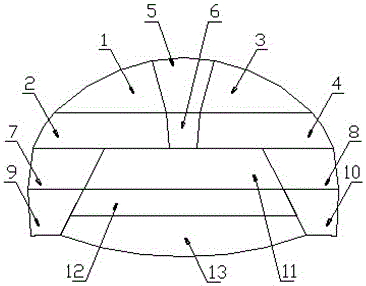

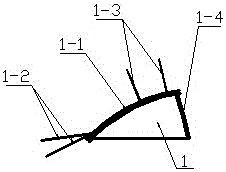

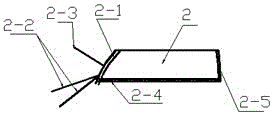

[0048] Embodiment 1: as Figure 1-Figure 15 As shown, an excavation and support structure for super-large section tunnels with weak surrounding rocks includes upper support and lower support. protection, the support of the upper step 3 of the right pilot pit, the support of the lower step 4 of the right pilot pit, the support of the upper part 5 of the middle partition wall, the support of the lower part 6 of the middle partition wall, and the lower support includes the left side wall The support of the upper step 7, the support of the lower step 9 of the left side wall, the support of the step 8 of the right side wall, the support of the lower step 10 of the right side wall, the support of the upper step 11 of the central core soil, The support of the lower step 12 of the central core soil and the support of the inverted arch 13, the excavation of the lower step 2 of the left pilot pit is 5m behind the excavation of the upper step 1 of the left pilot pit, and the excavation o...

Embodiment 2

[0058] Example 2: A construction method for the excavation and support structure of a super-large-section tunnel with weak surrounding rock. The super-large-section tunnel with weak surrounding rock adopts the excavation and support of the upper step and double side wall in six parts, and the lower step adopts the step method and divides the excavation into seven parts. support. Before the excavation of the tunnel, a Φ42mm small conduit 14 is installed in the 144° range of the arch to carry out the advance support of the arch, and then the tunnel section is divided into thirteen parts according to a certain order for excavation, which specifically includes the following steps:

[0059] Step 1. Under the advanced support of the small conduit, excavate the upper step of the left pilot pit first, which is an approximate triangle shape, with a bottom width of 9.56m, a height of 4.55m, and an area of 27m 2 , and timely construction of the initial support arch 1, the lock foot anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com