Super-long span tunnel excavation and support construction method

A tunnel excavation and construction method technology, which is applied in the direction of tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of high safety risks, slow construction progress, and many temporary supports, and achieve safe and reliable construction, less process change, and construction large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

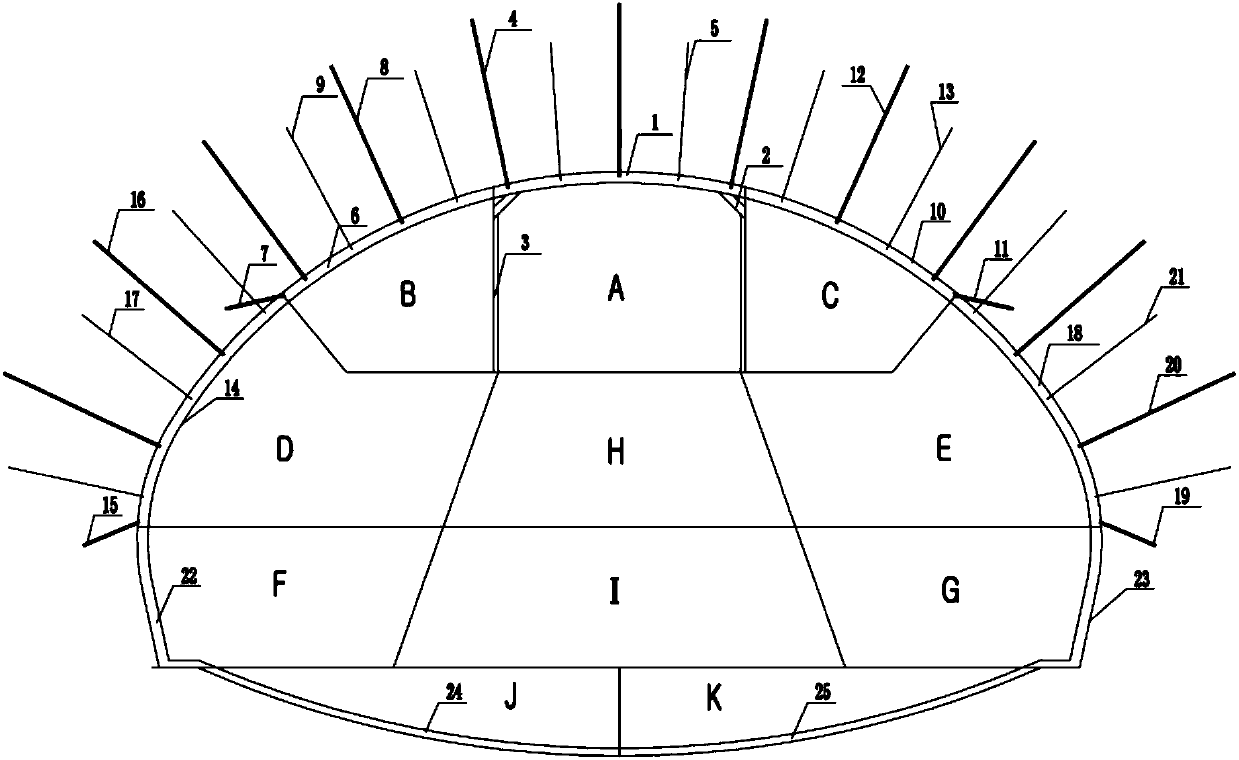

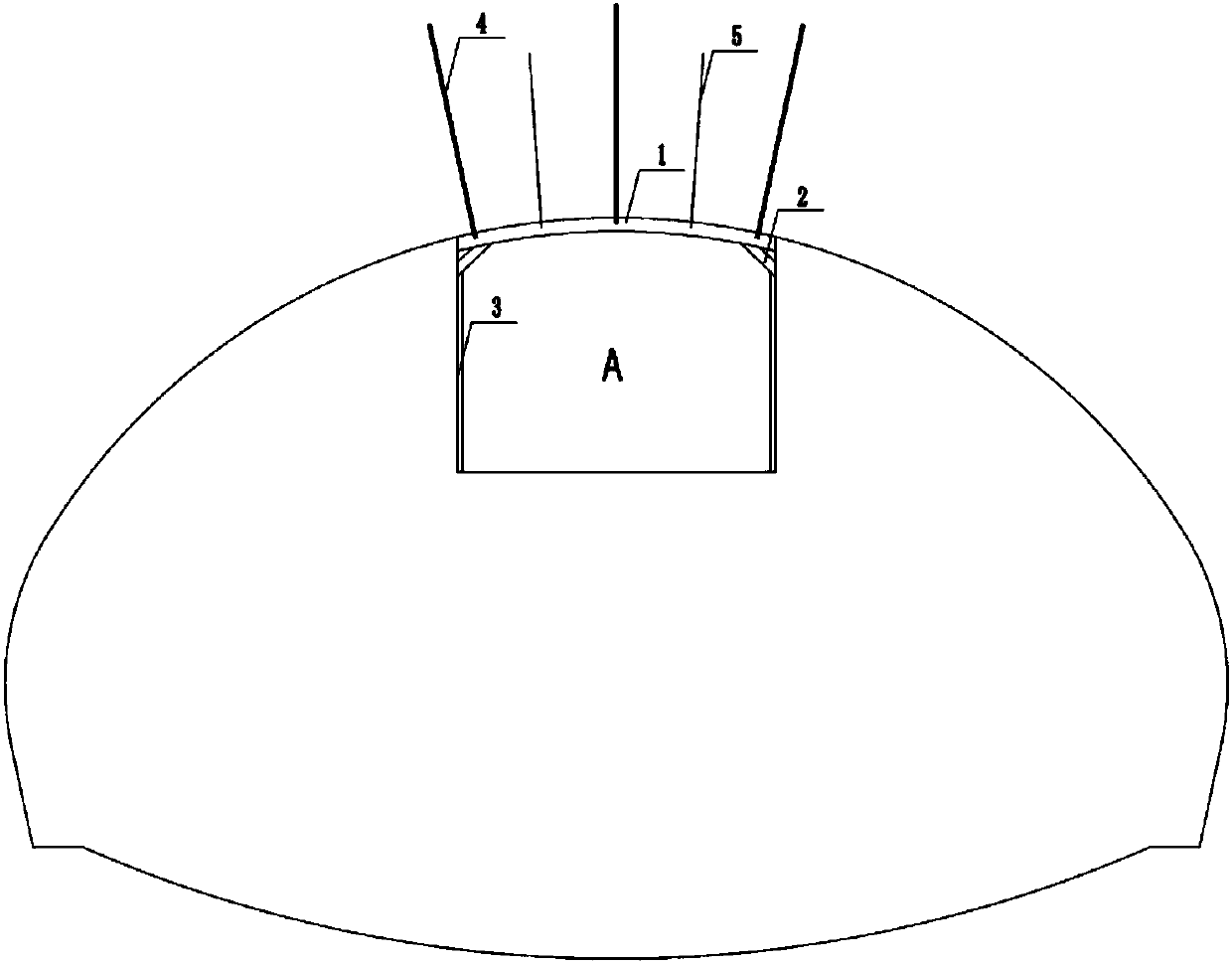

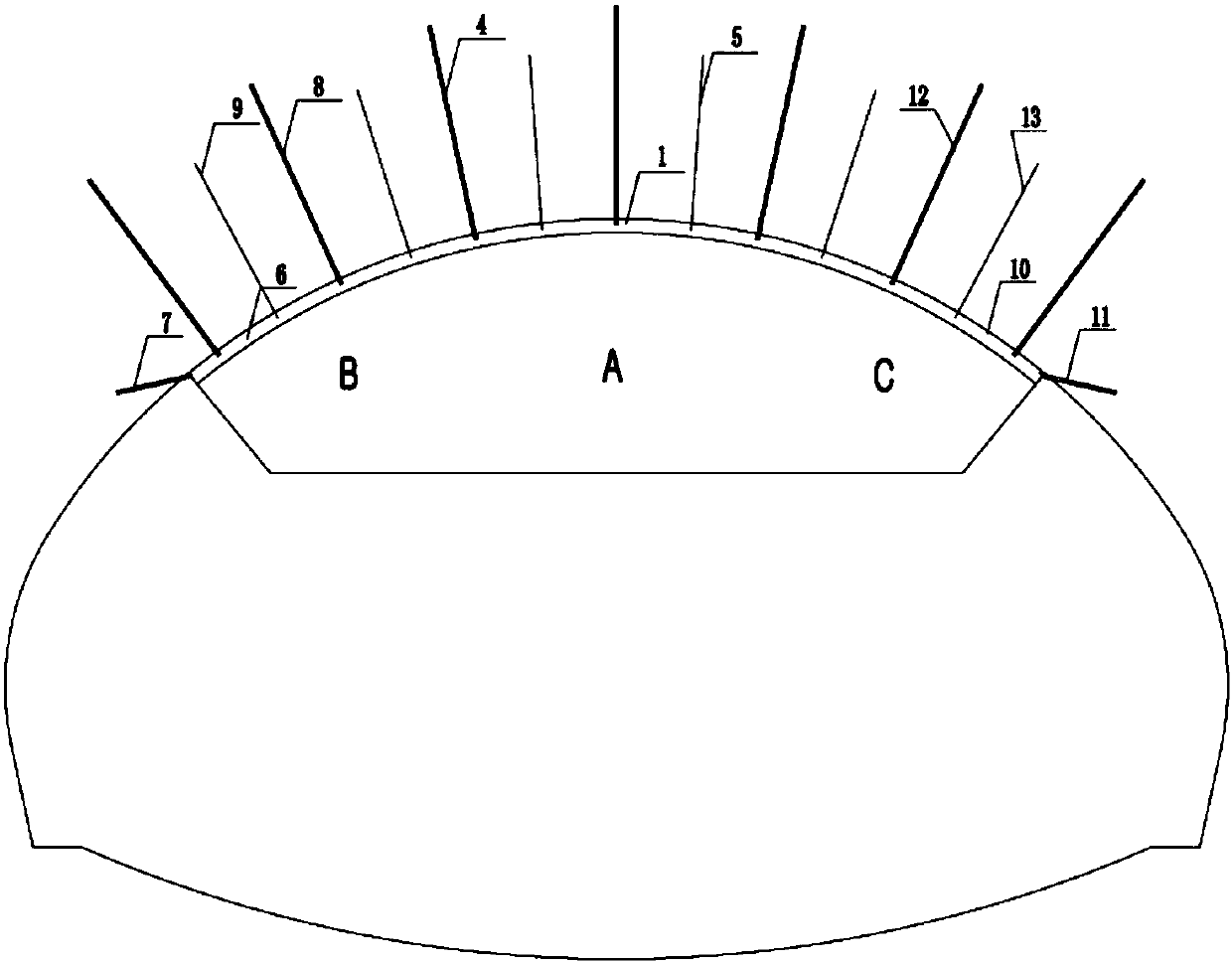

[0058] Please also see Figure 1-Figure 4 , The present embodiment provides a construction method for excavation and support of a super-long-span tunnel. The surrounding rock of the super-long-span tunnel is V-level strongly weathered granite, and the excavation section is 19.7m high and 32.7m wide. In this embodiment, according to the principle that the horizontal and vertical directions are basically uniform, the large-section tunnel is divided into eleven parts for construction. The eleven parts include the left hole B on the top floor, the middle hole A on the top floor, and the right side of the top floor from top to bottom and from left to right. Hole C, hole D on the left side of the middle step, core soil H in the middle part of the middle step, hole E on the right side of the middle step, hole F on the left side of the lower step, core soil I in the middle part of the lower step, hole G on the right side of the lower step, left inverted arch J and right inverted Arch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com