Tunnel dredging method suitable for railway large section IV, V class rock tunnel

A large-section and tunnel technology, which is applied to the excavation of V-level surrounding rock tunnels and the IV field of large-section railways, can solve the problems of unstable progress, low work efficiency, unstable construction operations, etc., and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

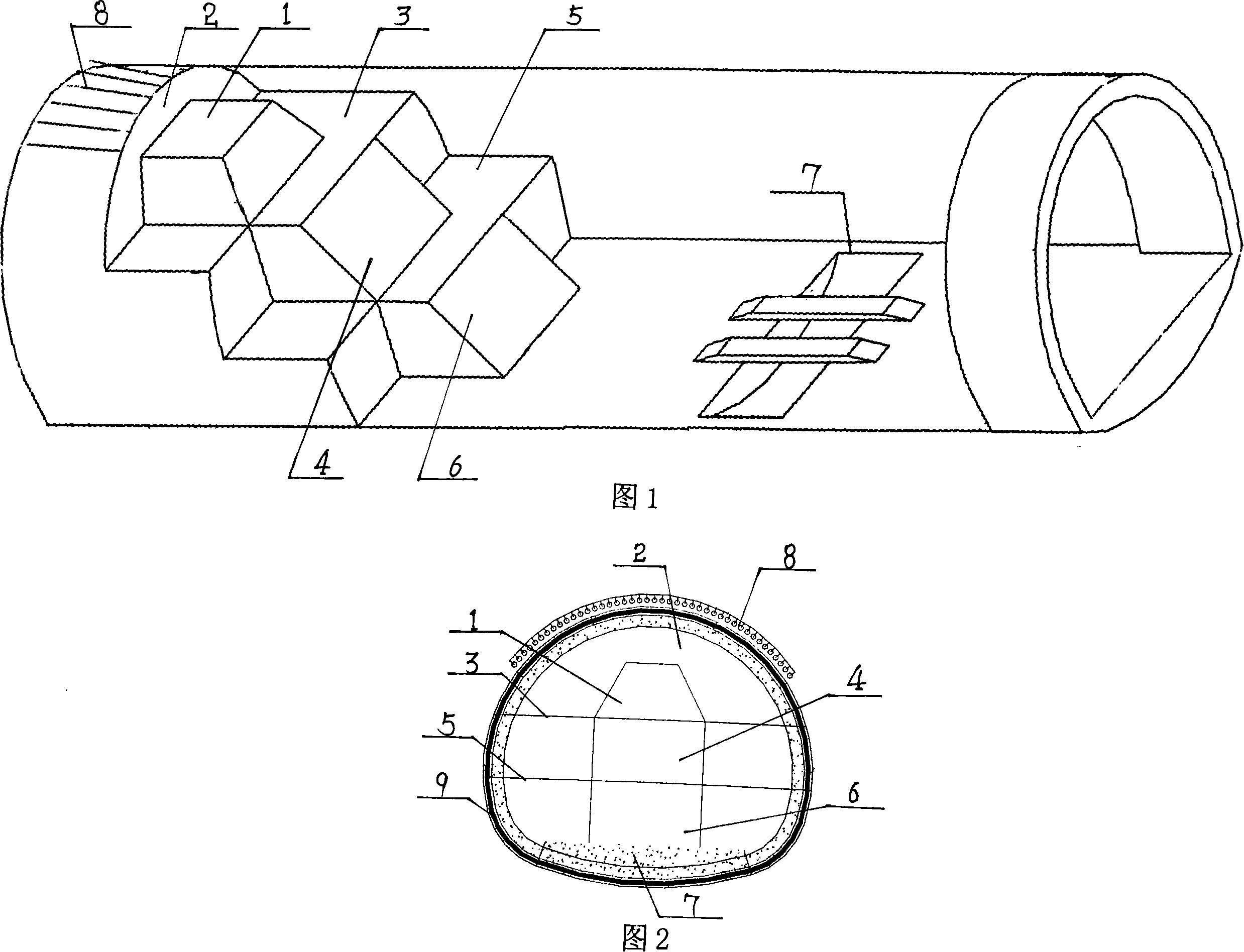

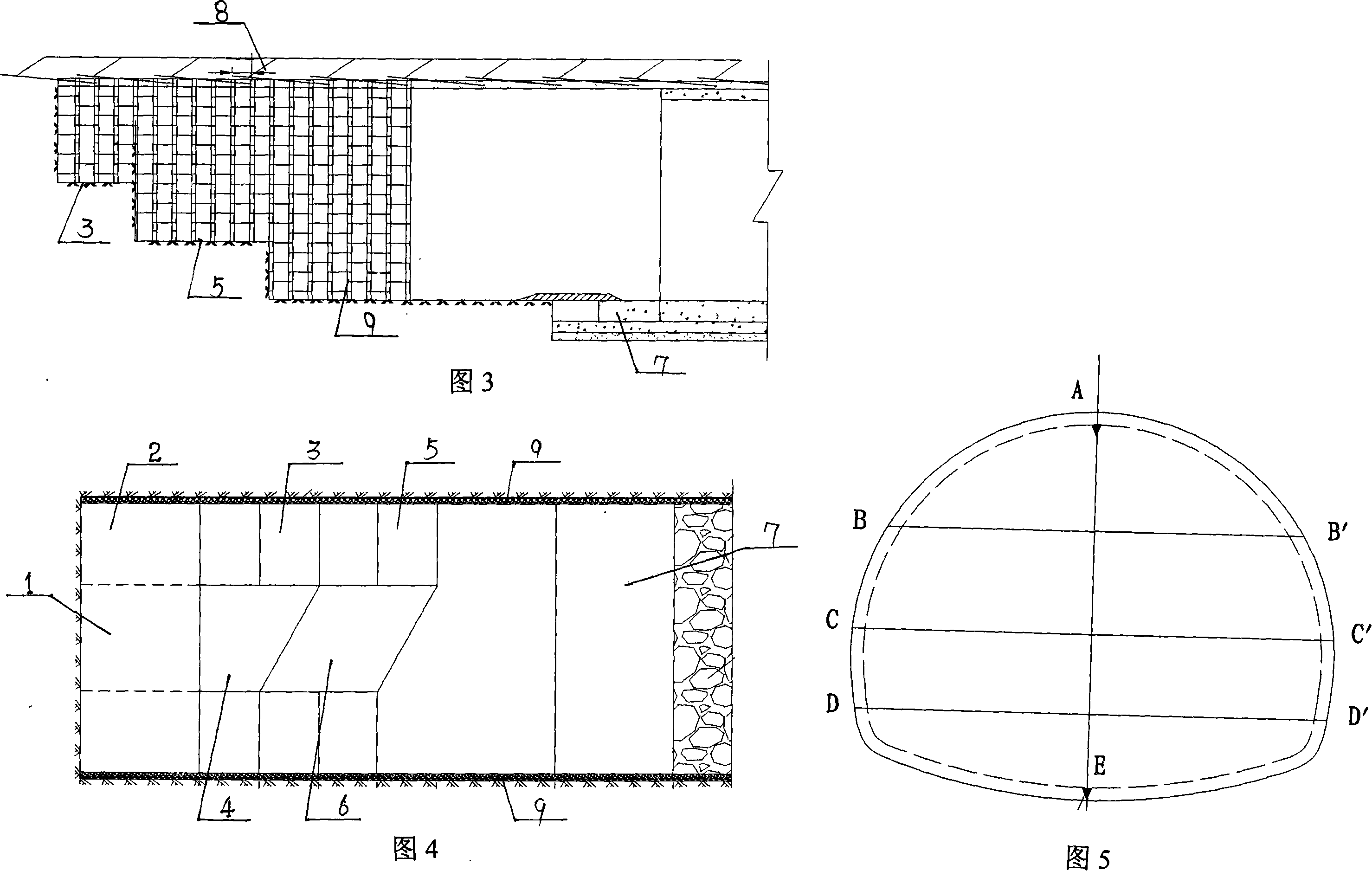

[0022] An excavation method suitable for railway large-section IV and V-level surrounding rock tunnels. First, according to the tunnel span and height requirements, the surrounding rock is excavated into a ladder shape with a lower step 5 and a middle step 3, and then includes the following steps: A , After the advanced support is applied, excavate the arc-shaped guide pit 2 of the arch along the excavation contour line, the height of the arc-shaped guide pit 2 is 3.0-4.0m, and immediately spray 3-5cm thick concrete to seal , and reserve the core soil in the middle as the upper step 1, and at the same time implement the initial support of the arch. It is 1.5-2.5m, and the excavation cycle footage is determined according to the distance between the initial support steel frames; B. Under the protection of the arch support, the left and right side walls of the middle steps 3 are excavated alternately and the core soil 4 is reserved. For the initial support, the excavation cycle f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com