Construction method for cast-in-place of continuous beam at turnout junction for passenger transport line in seawall area by false work method

A passenger dedicated line and construction method technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of high cost and poor construction safety, and achieve the effect of simple construction, large construction space and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

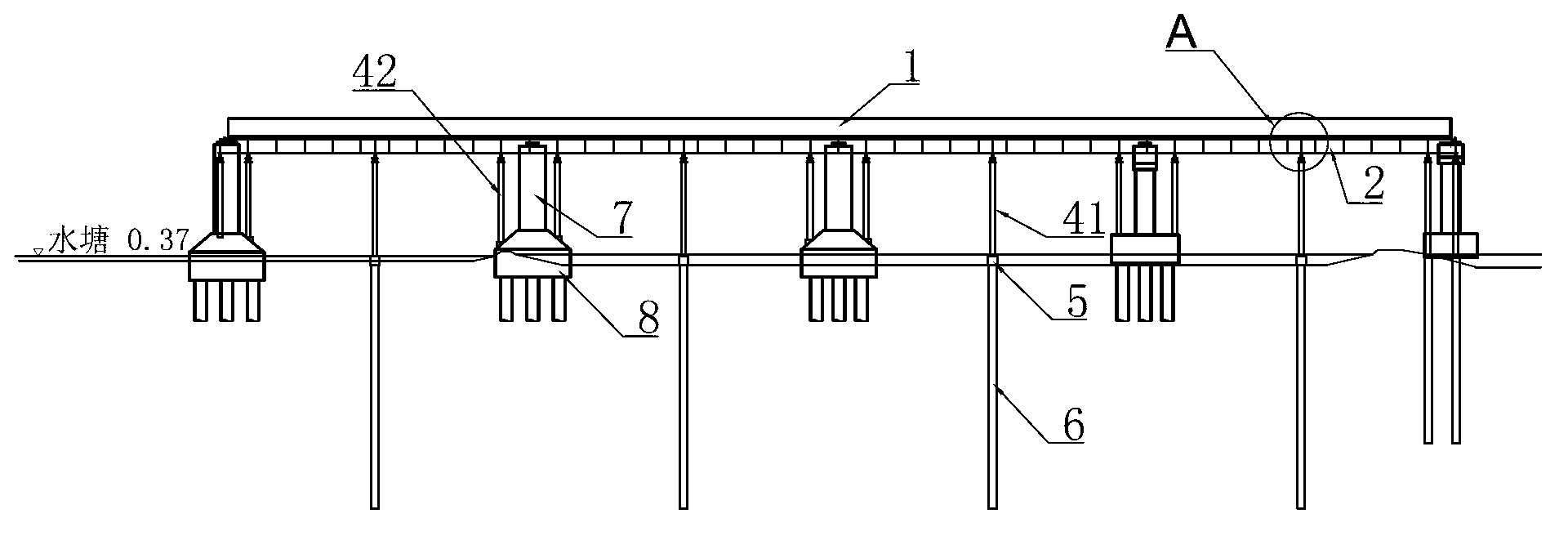

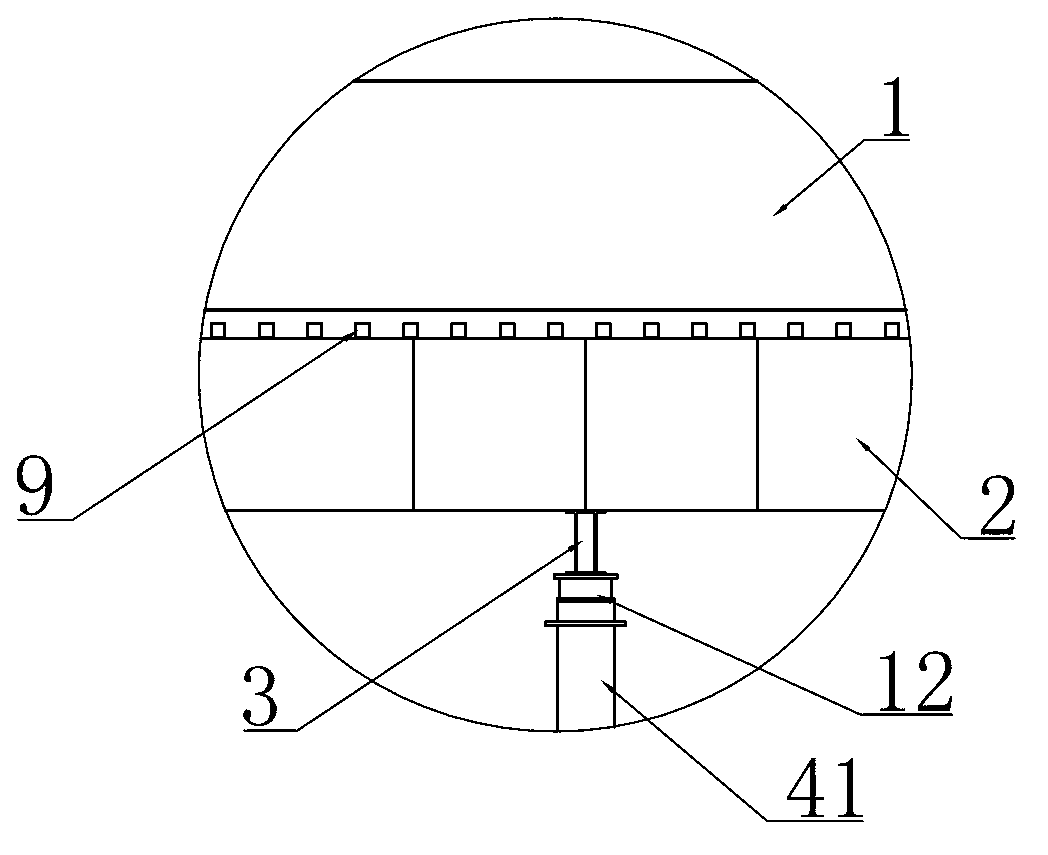

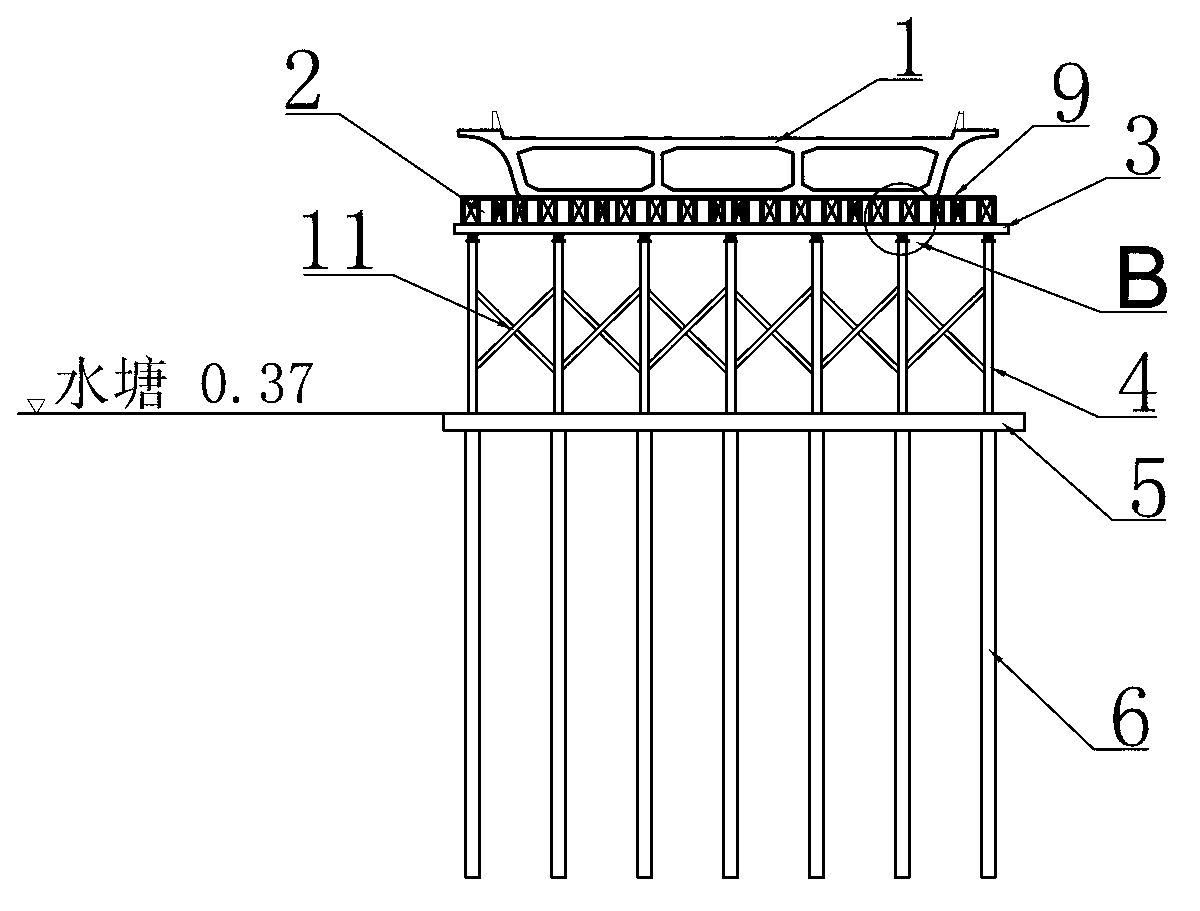

[0017] Combine below Figure 1 to Figure 5 The implementation steps of the cast-in-place turnout continuous beam construction method of the Haitang District Passenger Dedicated Line of the present invention are described in detail as follows:

[0018] 1. Ground treatment:

[0019] Drilled cast-in-situ pile 6 is used for construction with positive circulation drilling rig, and C30 underwater concrete pouring. According to the geological survey data of the design unit, the friction pile is designed according to the design, and enters the fully weathered rock formation. reinforced-concrete structure.

[0020] 2. Bracket erection:

[0021] 1) The steel pipe 4 is used as the support column to transmit the upper load to the foundation. The steel pipe 4 includes a mid-span steel pipe 41 and a pier steel pipe 42 near the pier 7, wherein the mid-span steel pipe 41 is welded to the pre-embedded steel plate on the top of the transverse beam 5, and the pier steel pipe 42 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com