Prestress loading device connecting part

A technology of loading device and connecting parts, applied in excavation, construction, infrastructure engineering and other directions, can solve the problems of non-reusable, low supporting rigidity, difficult to control deformation, etc., to save construction cost, large construction space, convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

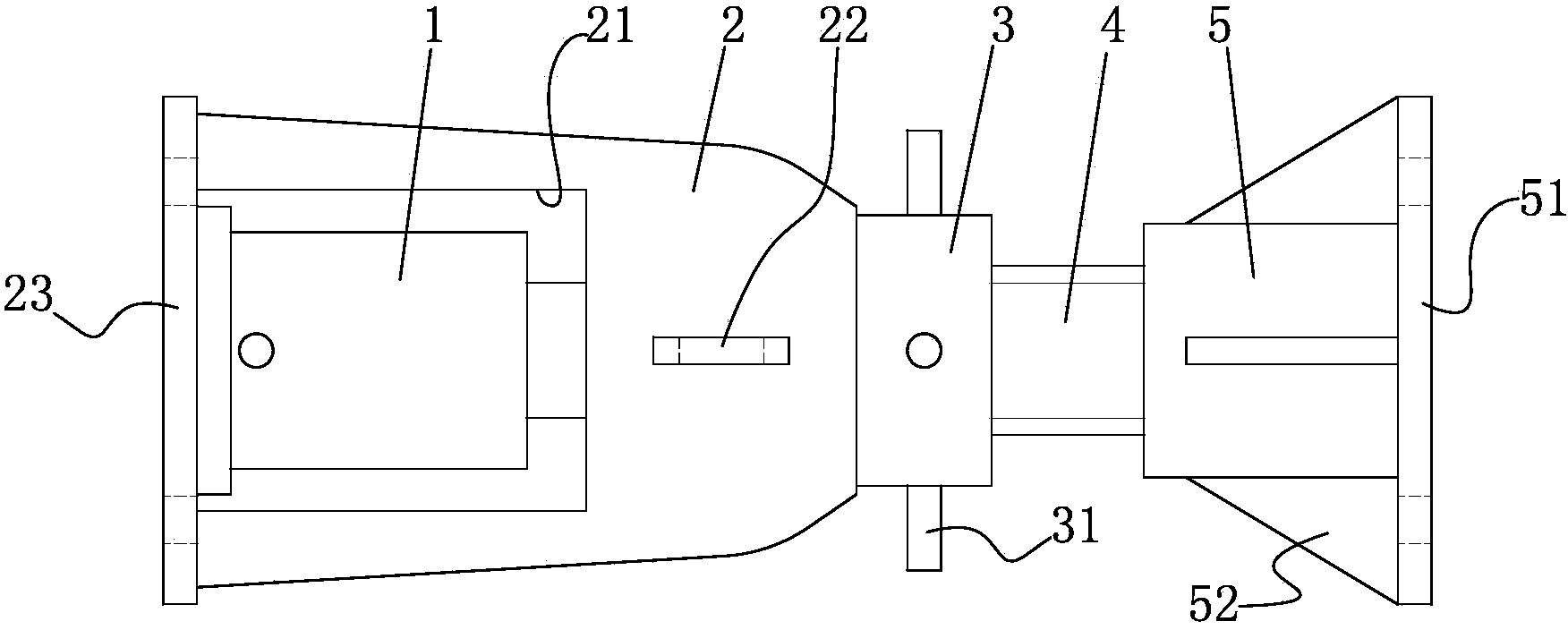

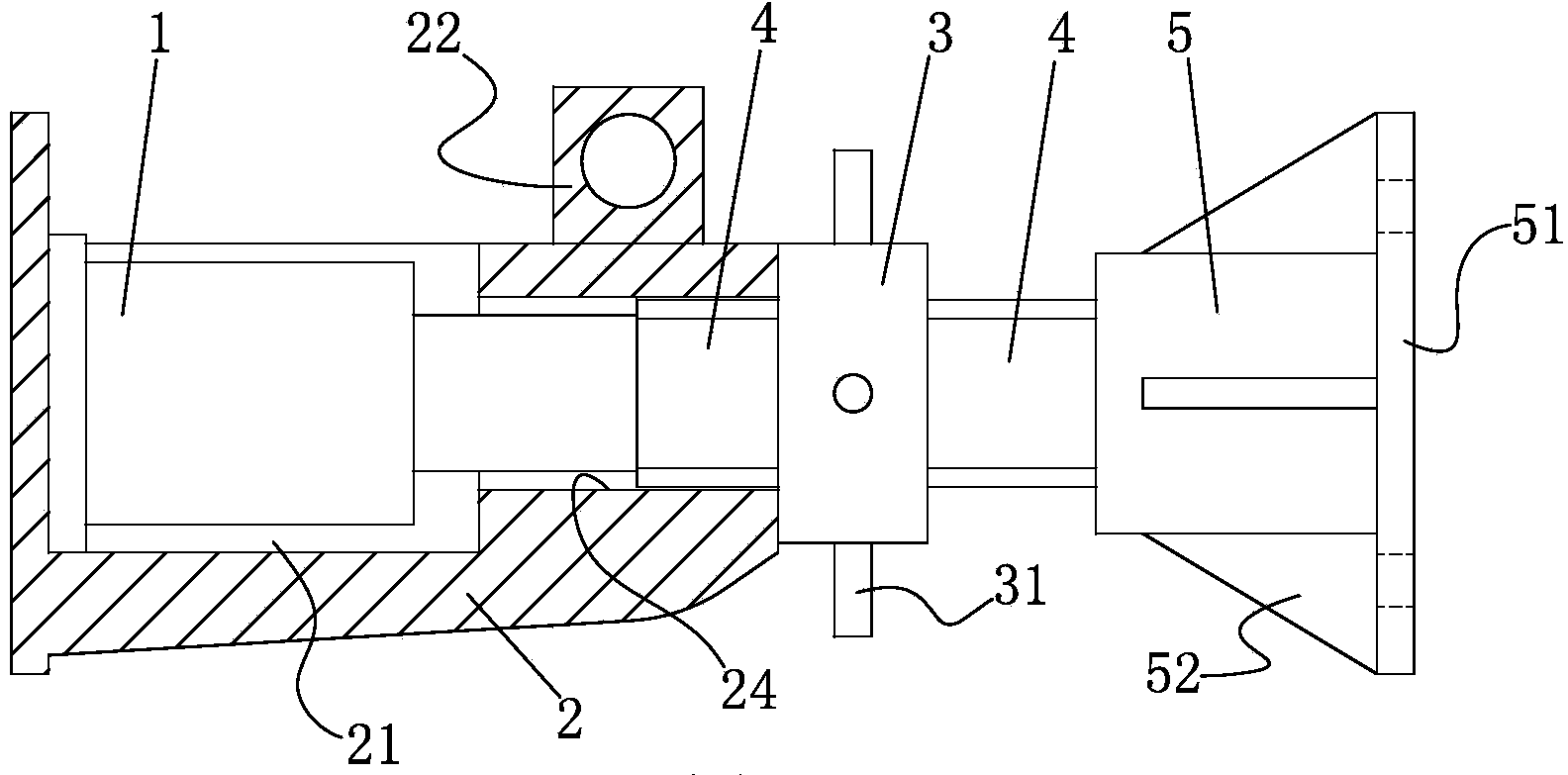

[0017] Such as figure 1 , figure 2 The connecting parts of the prestressed loading device shown include a loading base 2, a nut 3, a screw 4 and a screw base 5. The loading base 2 is provided with a groove 21 for placing the jack 1, and one side of the groove 21 is a screw plug. hole 24, the loading seat 2 is provided with a connecting flange A23 on the opposite side of the screw jack 24, one end of the screw 4 is inserted in the screw jack 24, the other end of the screw 4 is fixedly connected with the screw base 5, and the screw base 5 is in the The opposite side of the connecting screw 4 is provided with a connecting flange B51 , and the nut 3 capable of abutting against the loading seat 2 is threadedly connected to the part of the screw 4 other than the screw insertion hole 24 .

[0018] In this embodiment, the loading base 2 is provided with lifting lugs 22, and the lifting lugs 22 have lifting holes. There are four flange holes on the connecting flange A23, and the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com