Support structure for preventing settlement deformation of tunnels and construction method thereof

A support structure and tunnel settlement technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of not being able to closely adhere to long pipe sheds, increased construction costs, unfavorable force bearing combination of long pipe sheds and initial support, etc. , to achieve the effect of improving labor efficiency, large construction space and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in combination with specific embodiments.

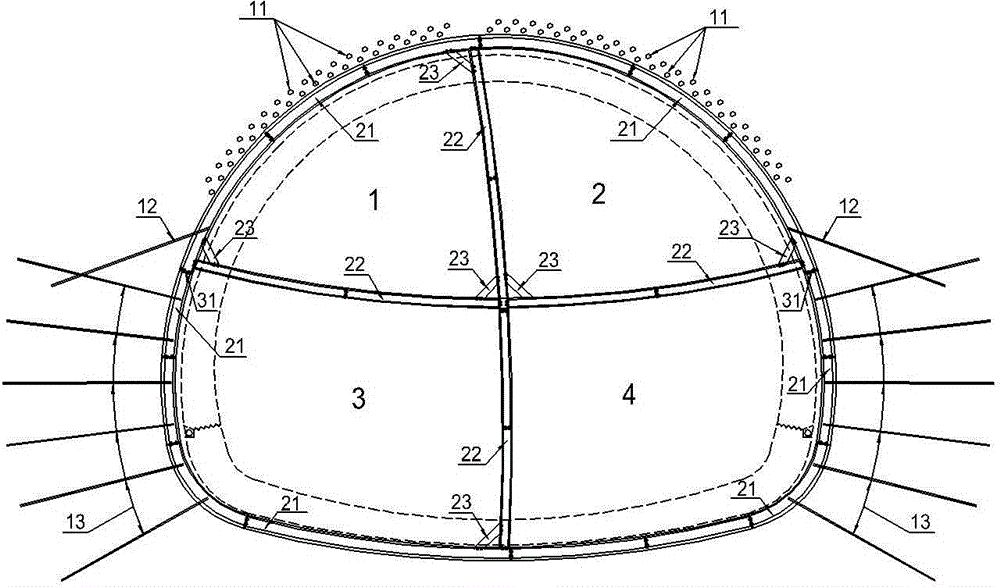

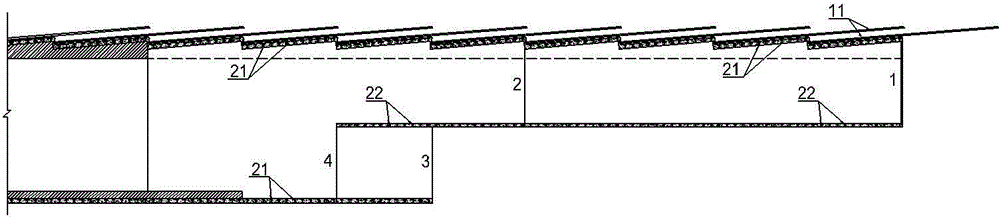

[0049] The support structure for preventing tunnel settlement and deformation involved in the present invention is excavated by the cross-middle partition method, and the tunnel is divided into four parts for excavation, namely, the left pilot tunnel for the upper step, the right pilot tunnel for the upper step, the left pilot tunnel for the lower step and the lower tunnel for the lower step. Step right guide hole.

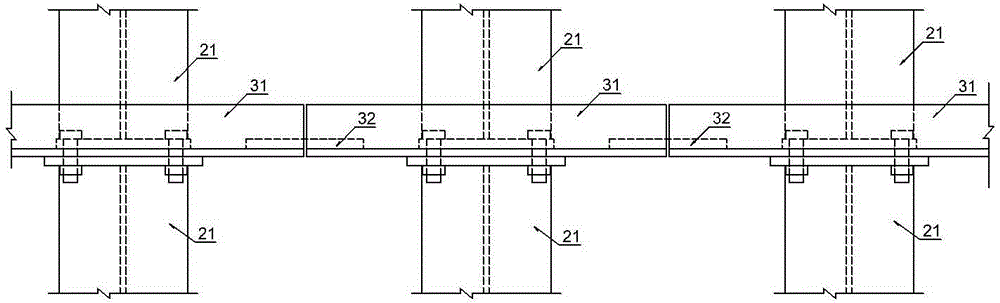

[0050] The support structure includes a ring-shaped permanent steel arch 21 in the tunnel. The permanent steel arch 21 is composed of parallel multi-ring variable-section units along the longitudinal direction of the tunnel. The longitudinal section is zigzag. Long tube shed 11, small grouting conduits 13 are evenly arranged outside the side walls on both sides of the permanent steel arch 21, and the bottom ends of both sides of the permanent steel arch 21 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com