Fire-retardant thermoplastic polyolefin waterproof roll and preparation method thereof

A thermoplastic polyolefin, waterproof coil technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problem of not fully considering the flame retardancy of the coil and only reaching B1 level. , to achieve safe and reliable waterproof effect, protect life and property safety, and ensure the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The polyester mesh is used as the middle reinforcement layer. The mesh has a warp fineness of 900D, a weft fineness of 1000D, and the total thickness of the product is 1.50mm.

[0034] The components and parts by weight of each layer are:

[0035] serial number

raw material name

Flame retardant TPO layer on the upper surface

Flame retardant TPO layer on the lower surface

1

TPO

100

100

2

Decabromodiphenylethane

8

8

3

2

2

[0036] 4

Zinc borate

2

2

5

3

3

6

filler

10

13

7

Titanium dioxide

3

0

8

Compatibilizer

3

3

9

1

1

10

light stabilizer

0.75

0.5

11

0.75

0.5

12

black female

0

0.3

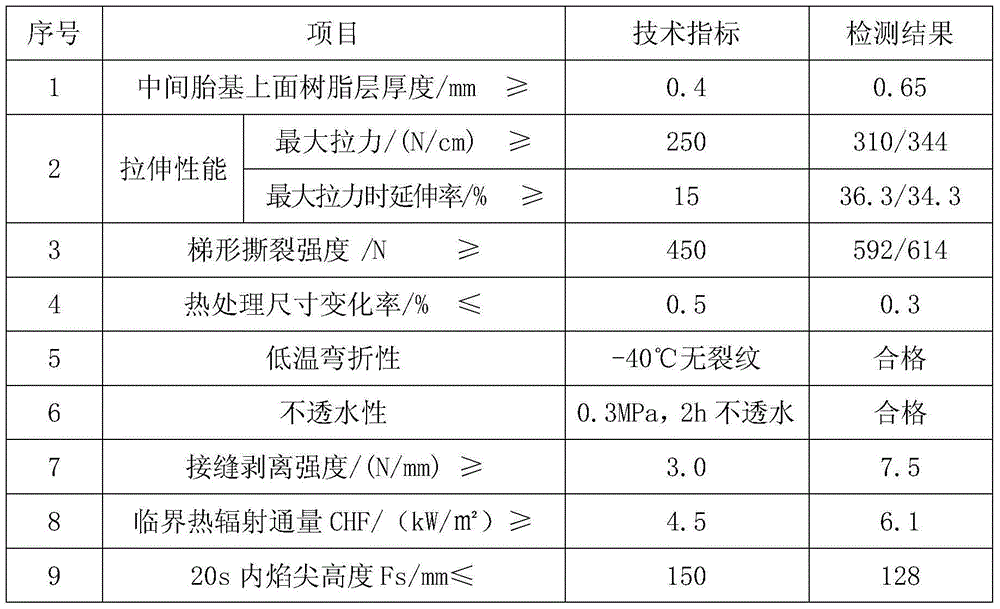

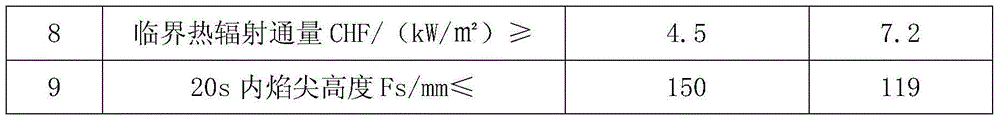

[0037] In accordance with GB 27789-2011 "Thermoplastic Polyolefin (...

Embodiment 2

[0043] The polyester mesh is used as the middle reinforcement layer. The mesh has a warp fineness of 1000D, a weft fineness of 1000D, and the total thickness of the product is 1.50mm.

[0044] The components and parts by weight of each layer are:

[0045] serial number

raw material name

Flame retardant TPO layer on the upper surface

Flame retardant TPO layer on the lower surface

1

TPO

100

100

2

Decabromodiphenylethane

10

10

3

3

3

4

Zinc borate

2

2

5

5

5

6

filler

5

8

7

Titanium dioxide

3

0

8

Compatibilizer

3

3

9

1

1

10

light stabilizer

0.75

0.5

11

0.75

0.5

12

black female

0

0.3

[0046] In accordance with GB 27789-2011 "Thermoplastic Polyolefin (TPO) Waterproof Me...

Embodiment 3

[0053] The polyester mesh is used as the middle reinforcement layer. The mesh has a warp fineness of 1000D, a weft fineness of 1300D, and the total thickness of the product is 1.50mm.

[0054] The components and parts by weight of each layer are:

[0055] serial number

raw material name

Flame retardant TPO layer on the upper surface

Flame retardant TPO layer on the lower surface

1

TPO

100

100

2

Decabromodiphenylethane

12

12

3

3

3

4

Zinc borate

2

2

5

magnesium hydroxide

8

8

6

filler

0

3

7

Titanium dioxide

3

0

8

Compatibilizer

3

3

9

1

1

10

light stabilizer

0.75

0.5

11

0.75

0.5

12

black female

0

0.5

[0056] In accordance with GB 27789-2011 "Thermoplastic Polyolefin (TPO) Waterproof Me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com