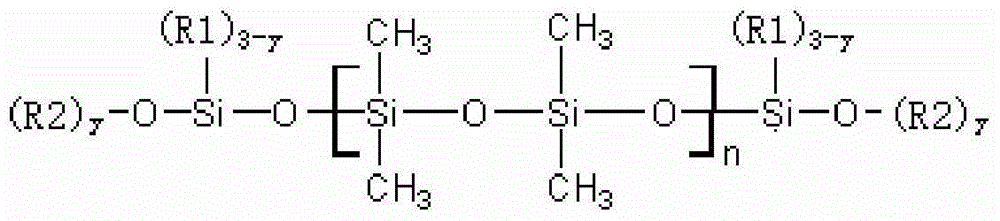

Transparent organic silicon LED light bar pouring sealant and preparation method thereof

A technology of LED light strips and silicone, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of turbidity during storage, affecting the light transmittance of products, and insufficient adhesiveness, etc. No performance drop, avoid colloid yellowing and transparency drop, ensure the effect of adhesion and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A transparent organic silicon LED light strip potting glue, prepared by the following method:

[0063] 1) Mix 70 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 1500mPa.s, 30 parts of α, ω-dimethoxysilyl polydimethylsiloxane with a viscosity of 50mPa.s Add alkanes, 10 parts of 100mPa.s MDT silicone oil and 10 parts of methyl MQ resin into the reaction kettle and mix evenly, then start to vacuumize and raise the temperature. hour, then cooled to normal temperature to obtain A component;

[0064] 2) Mix 30 parts of γ-aminopropyltrimethoxysilane, 40 parts of n-n-butyl-γ-aminopropyltrimethoxysilane and 30 parts of MDT silicone oil at 60°C for 4 hours under nitrogen protection, get tackifier;

[0065] 3) Add 40 parts of methyltriethoxysilane, 10 parts of methyl MQ resin, and 10 parts of MDT silicone oil into the reaction kettle, mix and stir at 80°C for 3 hours under the protection of nitrogen, and cool to normal temperature to obtain the reaction product; ...

Embodiment 2

[0070] A transparent organic silicon LED light strip potting glue, prepared by the following method:

[0071] 1) Mix 70 parts of α, ω-dihydroxypolydimethylphenylsiloxane with a viscosity of 1500mPa.s, 30 parts of α, ω-triethoxysilyl polydimethylsiloxane with a viscosity of 100mPa.s Add alkanes, 10 parts of 80mPa.s hydroxyl silicone oil and 20 parts of vinyl MQ resin into the reaction kettle and mix evenly, then start to vacuumize and raise the temperature. hour, then cooled to normal temperature to obtain A component;

[0072] 2) 40 parts of bis(trimethoxysilylpropyl) ammonia, 40 parts of n-n-butyl-γ-aminopropyltrimethoxysilane and 20 parts of 1,3,5-tris(trimethoxysilylpropyl) Polyisocyanate, under the protection of nitrogen, mixed and stirred at 40 ° C for 5 hours to obtain a tackifier;

[0073] 3) Add 10 parts of vinyltriethoxysilane, 20 parts of vinyl resin, and 20 parts of MDT silicone oil into the reaction kettle, mix and stir at 100°C for 3 hours under the protection o...

Embodiment 3

[0078] A transparent organic silicon LED light strip potting glue, prepared by the following method:

[0079] 1) Mix 70 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 500mPa.s, 30 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa.s, 10 parts of 100mPa .s of MDT silicone oil and 20 parts of methyl MTQ resin, put into the reaction kettle and mix evenly, then start to vacuumize and raise the temperature. At room temperature, A component was obtained.

[0080] 2) 50 parts of bis(trimethoxysilylpropyl)ammonia, 40 parts of n-n-butyl-γ-aminopropyltrimethoxysilane and 10 parts of hexamethyldisilazane were placed in the Mix and stir at 80°C for 3 hours to obtain a tackifier;

[0081] 3) Add 2 parts of vinyltriethoxysilane, 3 parts of polymethyltrimethoxysilane, 20 parts of methyl MQ resin, and 15 parts of MDT silicone oil into the reaction kettle, and mix and stir at 100°C for 3 hour, cooled to normal temperature to obtain the reaction product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com