Plugging structure for large-drawdown pipe well and construction method thereof

A construction method and tube well technology, which are applied in basic structure engineering, earthwork drilling, sealing/isolation, etc., to achieve the effect of ensuring waterproof effect, large economic and social benefits, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

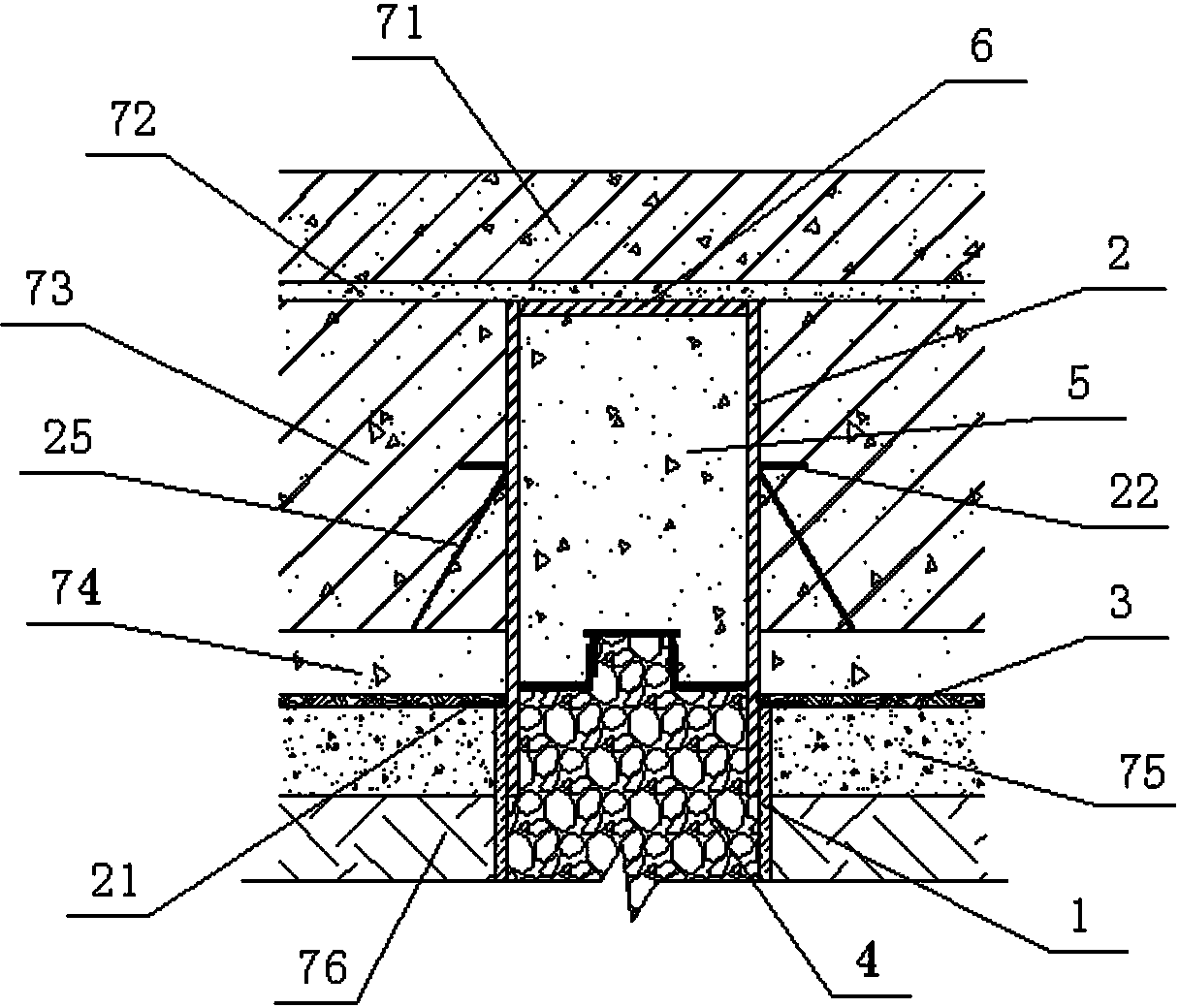

[0020] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0021] A large drawdown tube well plugging structure, including cement-free sand pipe 1 and steel casing 2, the steel casing 2 is made of Q235B steel pipe with a wall thickness of 5mm and a diameter of 275mm, and the length of the steel casing is the length of the raft foundation and the pad The distance between the bottom elevations is increased by 300mm. The steel casing 2 is welded with a steel plate water stop ring 22. The steel plate water stop ring 22 adopts a 5mm thick and 50mm wide annular Q235 steel plate and is located in the middle of the raft foundation. The steel casing 2 at the bottom level of the cushion is welded and connected with an anti-slip waterstop ring 21, the width of the anti-slip waterstop ring 21 is 30mm, the position is at the level of the bottom of the cushion, and the height of the weld seam is not less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com