Grommet

A technology for grommets and barrels, applied in the field of improving the installation workability of the grommets and wire harnesses, can solve the problems of reduced reliability of waterproof performance, etc., and achieve improved reliability, enhanced shape retention, and enhanced shape retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

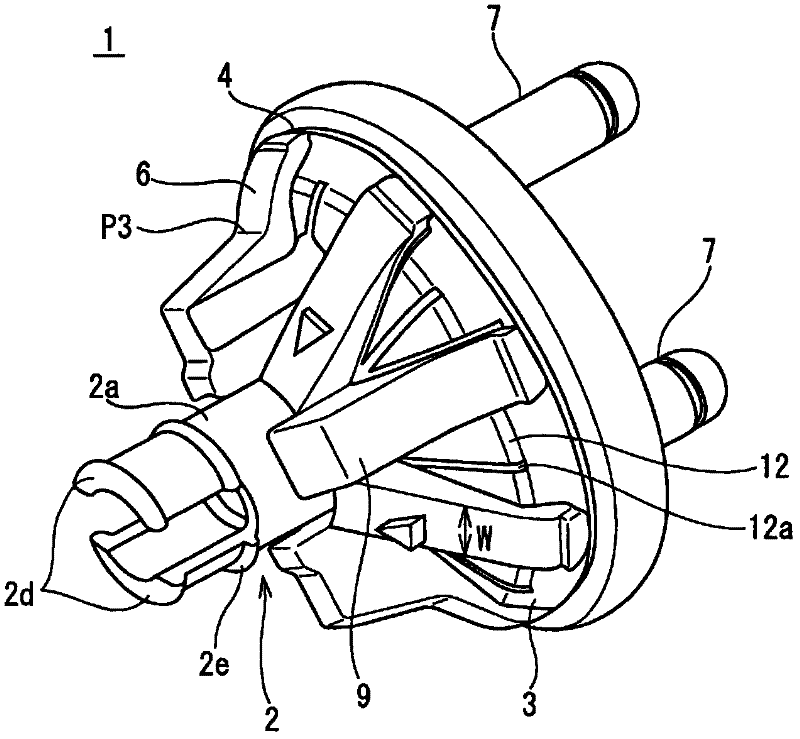

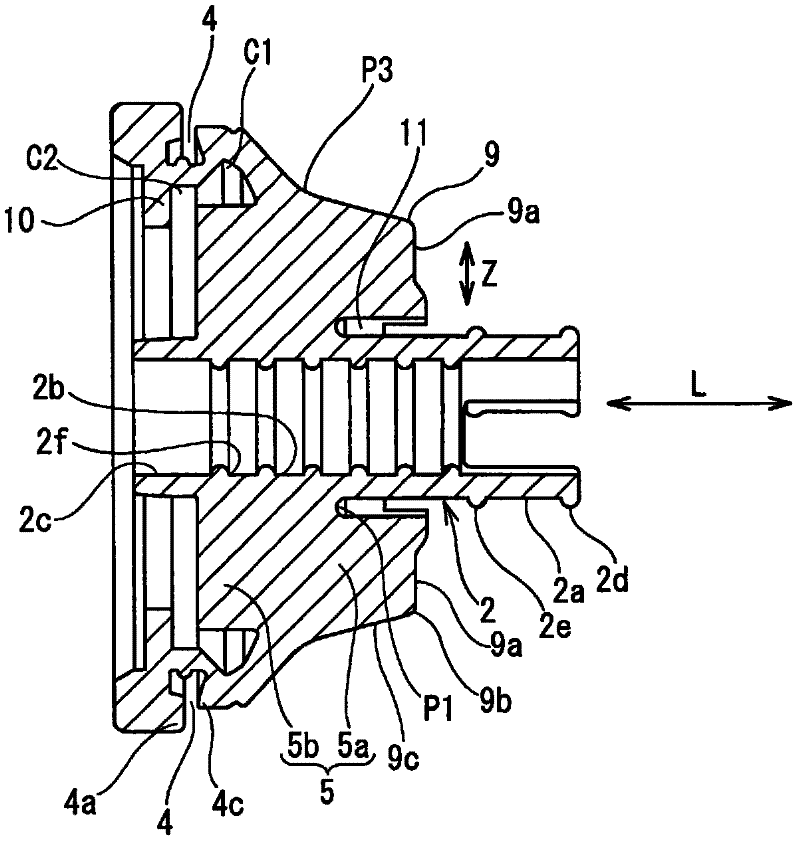

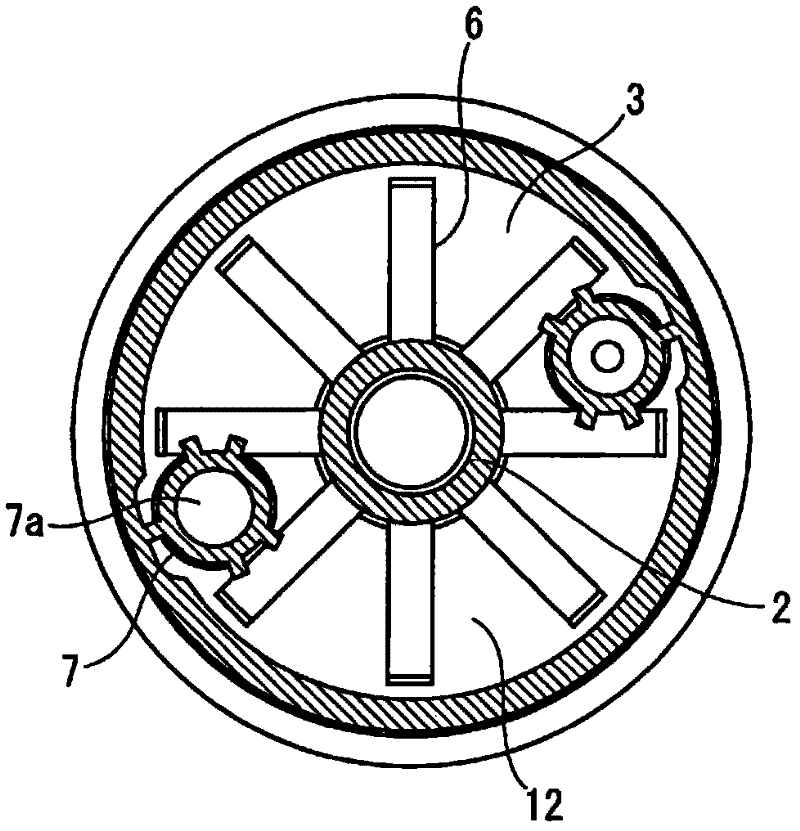

[0057] Refer to the following Figure 1 to Figure 8 Embodiments of the present invention will be described.

[0058] The grommet 1 of this embodiment and the above-mentioned conventional example Figure 9 Likewise, it is fixed in advance to the wire harness W / H that is routed from the engine compartment side (X) to the through hole H of the instrument panel P to the vehicle compartment side (Y).

[0059] The grommet 1 is integrally molded from rubber.

[0060] This grommet 1 has: a small-diameter cylindrical portion 2 that makes the wire harness close to and penetrates through it, and only the front end 2d of the side portion 2a is fixed by wrapping tape around the wire group of the wire harness W / H; The outer circumference of the middle part of the longitudinal direction of the part 2 is continuous, surrounds the other side part 2b of the small-diameter tube part 2 and expands in diameter; Annularly arranged; the inner flange 5 is arranged at intervals in the circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com