Motor push rod type power-assisted steering apparatus

An electric power steering and electric push rod technology, applied in the field of auto parts, can solve problems such as the inability to adjust and control the power assist characteristics in real time, the difficulty in coordinating the lightness of low-speed steering, and the increase in the size of the steering gear, so as to shorten the production and development cycle, High degree of assembly automation and the effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

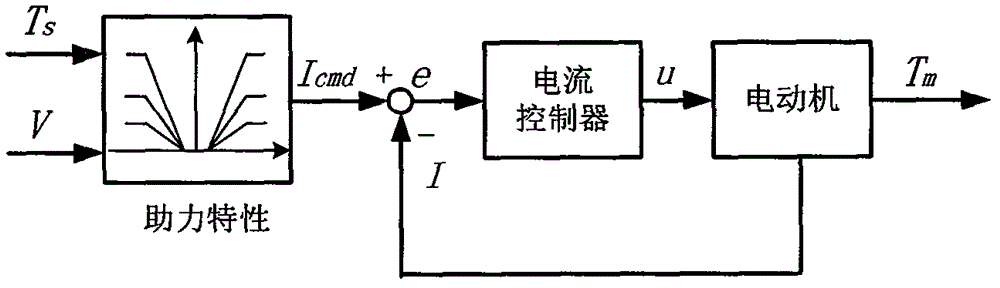

[0024] Such as figure 1 As shown, the electronic control unit according to the collected steering wheel torque T s Determine the target current Icmd of the booster motor with the vehicle speed V, and then perform feedback tracking control on the booster motor current according to the actual current I and target current Icmd of the booster motor.

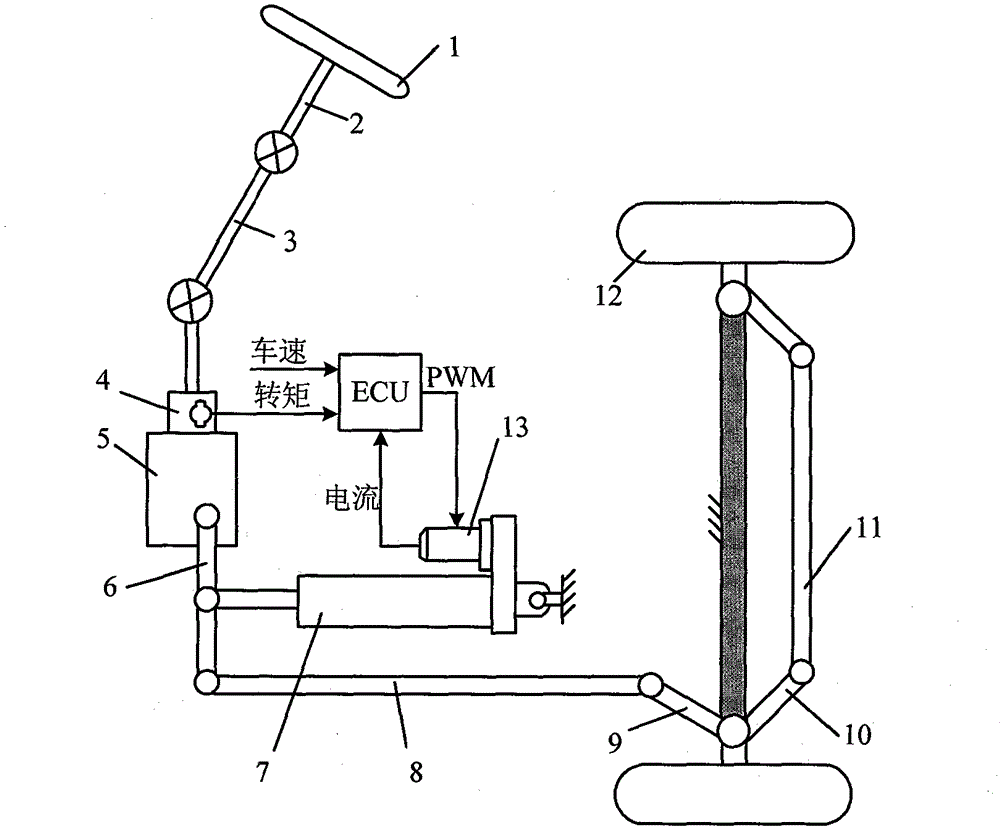

[0025] Such as figure 2 As shown, the working principle of the electric push rod type electric power steering device is: when the driver turns the steering wheel 1, the driver's torque is transmitted to the input shaft of the recirculating ball steering gear 5 through the steering shaft 2 and the steering transmission shaft 3, and then The input shaft of the recirculating ball steering gear 5 is provided with a torque measuring device 4, and the torque measuring device 4 sends the measured torque of the driver to the electronic control unit ECU, and the ECU controls the electric push rod according to the torque signal and combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com