Transmission intermediate shaft circlip automatic feeding and pressing mechanism

A technology of automatic feeding and intermediate shaft, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of manual assembly of the circlip, and achieve the effect of solving the difficulty of manual assembly, high degree of assembly automation, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

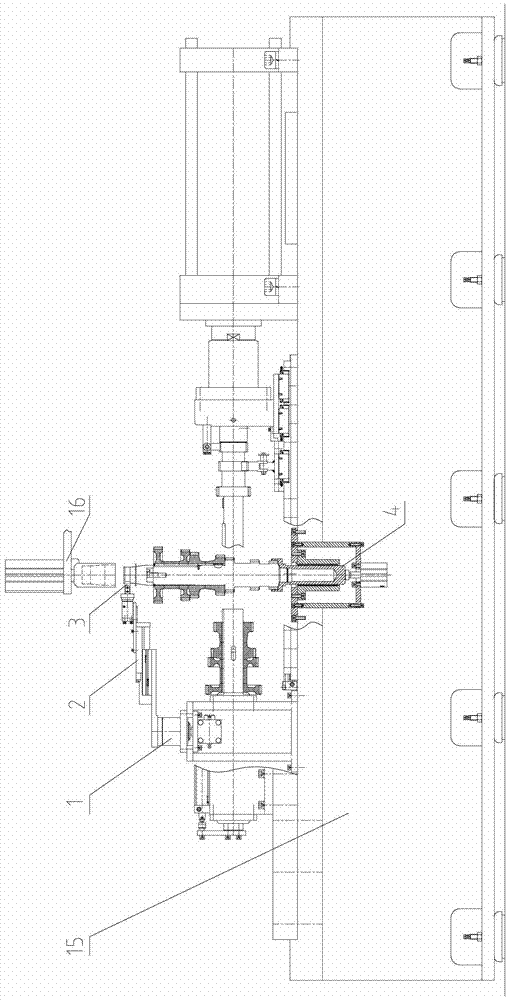

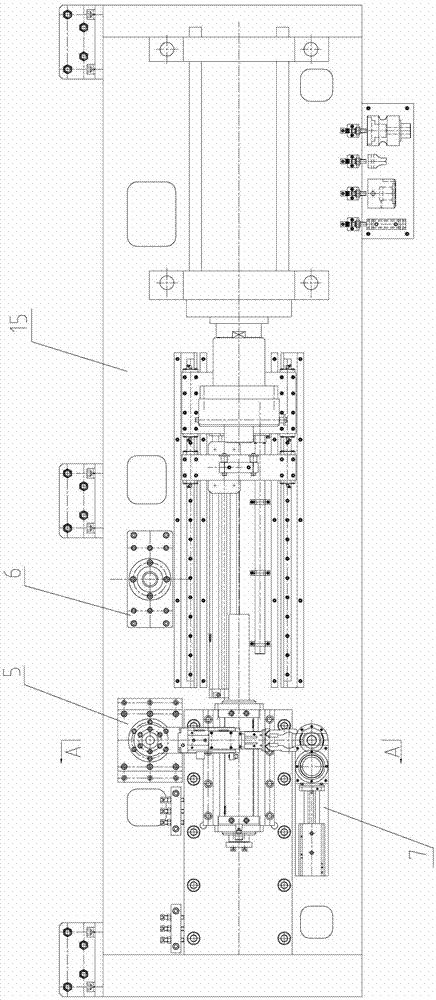

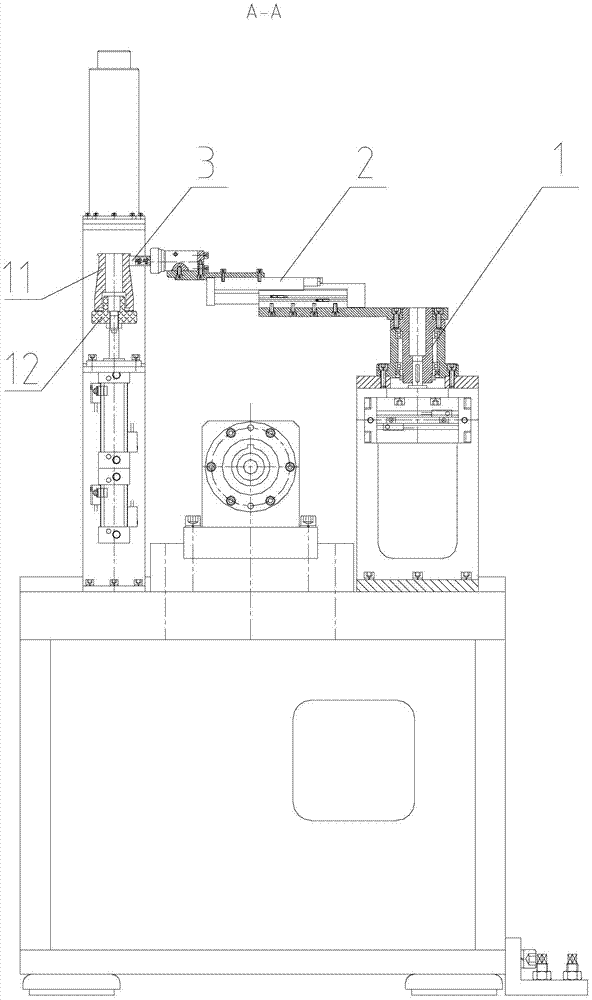

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-4 As shown, the present invention includes a body 15, a press-fitting device 16 and a snap spring feeding and conveying mechanism, wherein the body 15 is the body of an intermediate shaft horizontal press. The feeding conveying mechanism of the snap spring includes a snap spring installation mechanism 7 installed on the body 15, a holding and rotating mechanism 5, a snap ring cover tooling 11, a snap ring cover tooling positioning mechanism 14 and an intermediate shaft lifting mechanism 4, wherein the snap ring The spring cover frock 11 is positioned on the snap spring cover frock positioning mechanism 14, the clip spring installation mechanism 7 is arranged on the top of the clip spring cover frock 11, and the intermediate shaft of the clip spring to be pressed is vertically positioned on the intermediate shaft lifting mechanism 4; The circli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com