Washing machine clutch assembly automatic line

A technology of clutches and automatic lines, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production automation rate, large number of assembly workers, and high labor intensity of workers, so as to reduce labor intensity, reduce demand, and improve assembly The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

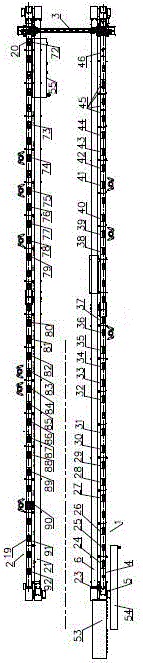

[0043] Such as figure 1 As shown, a washing machine clutch assembly automatic line, including shaft assembly automatic assembly line

[0044] 1. Clutch assembly automatic line 2 and cross-line transplanting device 3. The shaft assembly automatic assembly line 1 includes the shaft assembly assembly conveying line 4 , the shaft assembly assembly carrier 5 and the shaft assembly assembly carrier automatic return line 6 . The shaft assembly assembly carrier 5 is conveyed from the initial end to the end of the shaft assembly assembly conveyor line 4 through the shaft assembly assembly conveyor line 4, and automatically returned by the shaft assembly assembly carrier at the end of the shaft assembly assembly conveyor line 4 Line 6 returns to the initial end of shaft assembly assembly conveyor line 4.

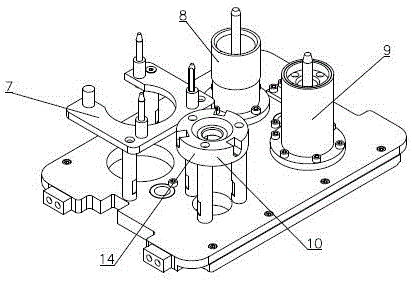

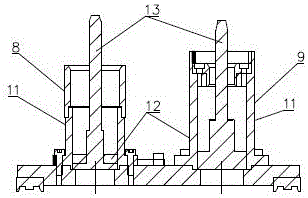

[0045] Such as figure 2 As shown in and 3, the shaft assembly assembly carrier 5 includes a pallet and a cover mounted on the pallet

[0046] Positioning tool 7, dehydration shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com