A kind of automatic assembly mechanism and working method of automobile inductance

An assembly mechanism and working method technology, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve problems such as unsatisfactory effects, low efficiency, and difficult quality assurance, and achieve a high degree of assembly automation and avoid efficiency Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

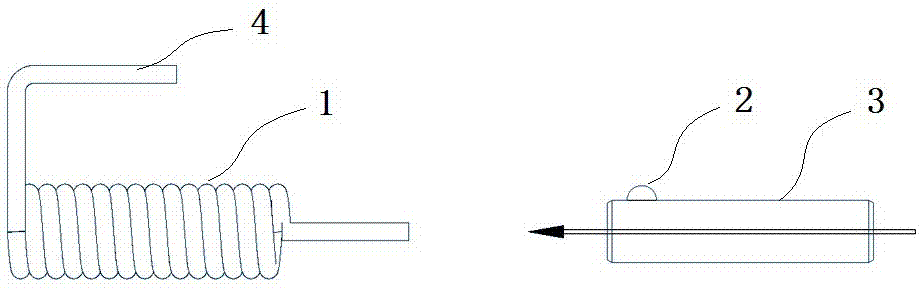

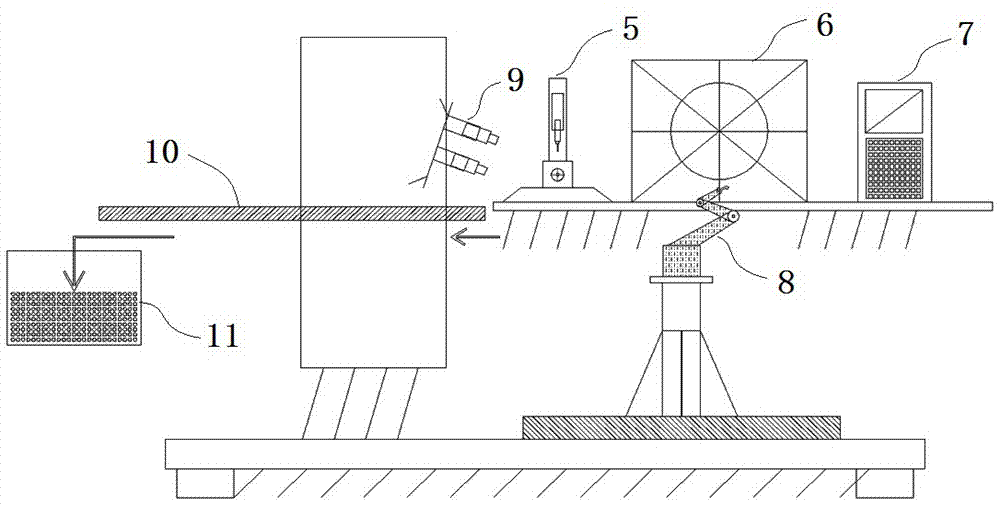

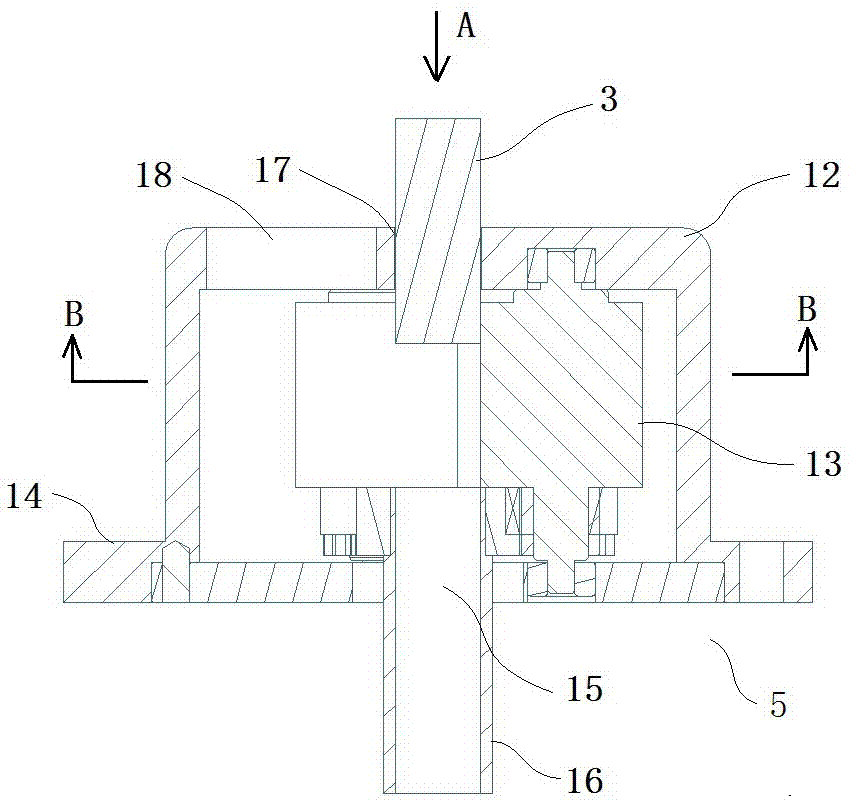

[0031] Example 1: Such as figure 2 , 6 As shown in 7, this embodiment specifically relates to an automated assembly mechanism for automobile inductors and a working method thereof. The automated assembly mechanism is mainly used to assemble the coil 1 with the pin 4 and the magnetic core 3 to obtain the automobile inductor.

[0032] Such as Figure 2-7 As shown, the automated assembly mechanism in this embodiment mainly includes a winding forming machine 6, a coil clamping device 8, an assembly head 5, a central control system 7, an image detection device 9, a conveyor belt 10, and a finished product box 11, among which:

[0033] The winding forming machine 6 is a coreless winding forming machine, it can also be a core winding forming machine or a special winding forming machine, which is used to wind and produce the coil 1, and the tail end of the coil 1 has a bending point toward its beginning. Pin 4, pin 4 is parallel to the body of coil 1;

[0034] The coil clamping device 8 is ...

Embodiment 2

[0047] Example 2: Such as Figure 2-7 As shown, this embodiment specifically relates to an automated assembly mechanism for automotive inductors and its working method. The difference between the automated assembly mechanism and the automated assembly mechanism in Embodiment 1 is that the rubber wheel 13 has a spiral function, and the magnetic core clamps The wheel set can rotate and advance the magnetic core 3 while clamping the magnetic core 3, and the rest of the structure is the same.

[0048] Such as Figure 2-7 As shown, the working method of the automotive inductor automatic assembly mechanism in this embodiment includes the following steps:

[0049] (1) Winding forming machine 6 produces coil 1 with pin 4;

[0050] (2) The coil clamping device 8 travels to the top of the winding forming machine 6 and clamps the end position of the coil 1, and then moves the coil 1 to directly above the assembly head 5, that is, directly above the core hole 17;

[0051] (3) Both the coil 1 and ...

Embodiment 3

[0056] Example 3: Such as figure 2 , 8 , 9, and 10, this embodiment specifically relates to an automated assembly mechanism for automotive inductors and its working method. The automated assembly mechanism is mainly used to assemble the leadless coil 1 with the magnetic core 3 to obtain automotive inductors. .

[0057] The difference between the automated assembly mechanism in this embodiment and the assembly mechanism in Example 1 is that the assembly head base 5 is an external-rotation assembly head with no pin relief holes on it, which is suitable for a leadless coil with a magnetic core. The assembling between the room; the rest of the structure and specific working methods are the same as those described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com