Forward and inverse solution method of five-shaft numerical control drilling machine tool with feed shaft swinging wit AB shaft

A technology for controlling holes and feed axes, used in program control, computer control, general control systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

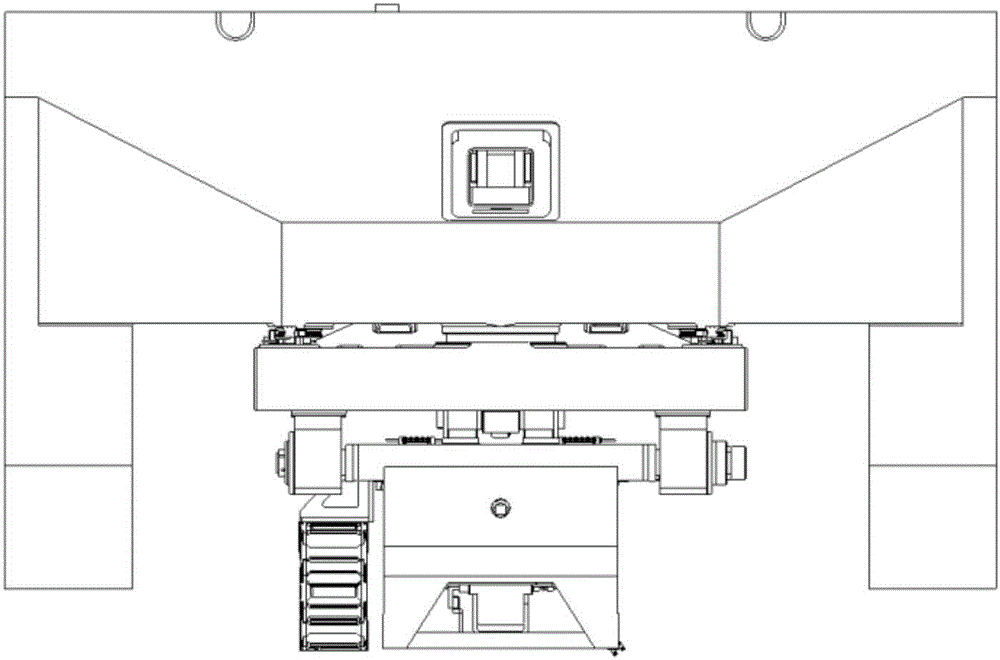

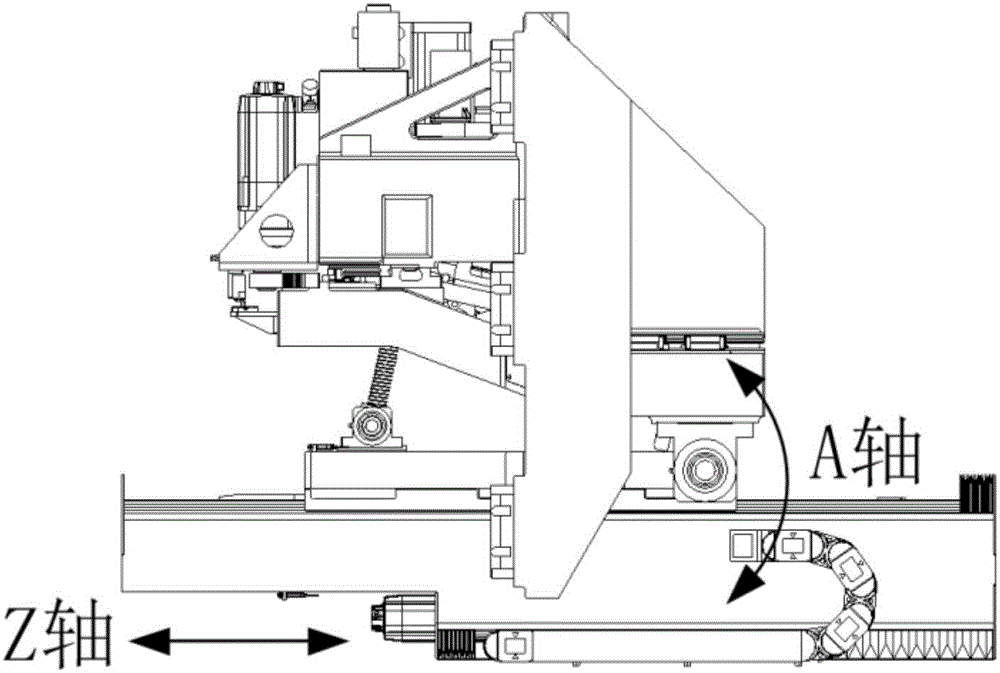

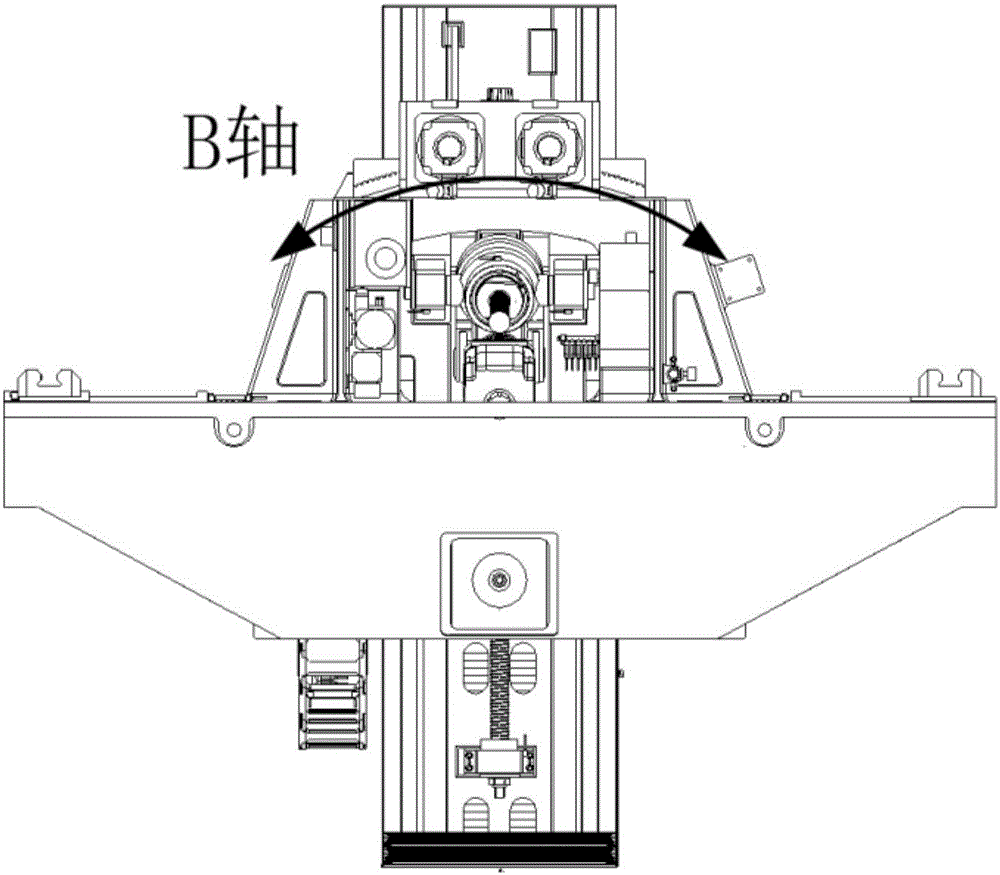

[0054] Figure 1 ~ Figure 3 What is shown is the BAZ axis component of the special-shaped five-axis number control hole machine tool, which is a structural form in which the feed axis swings with the AB axis. The forward and reverse solution method of the five-axis number control hole machine tool in which the feed axis swings with the AB axis proposed in this embodiment Applied to this special-shaped five-axis number control hole machine tool.

[0055] like Figure 4 As shown, in this embodiment, the steps of a positive and negative solution method for a five-axis digital control hole machine tool in which the feed axis swings with the AB axis are as follows:

[0056] (1) In the special-shaped five-axis number control hole machine tool, establish the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com