Sealing part assembly

A seal and assembly technology, applied in the field of water pump seal assembly structure, can solve the problems of difficult to get a perfect combination, the sealing end face is not tight, affecting the normal elastic value of the seal, etc., to achieve a high degree of assembly automation, Reliable sealing performance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

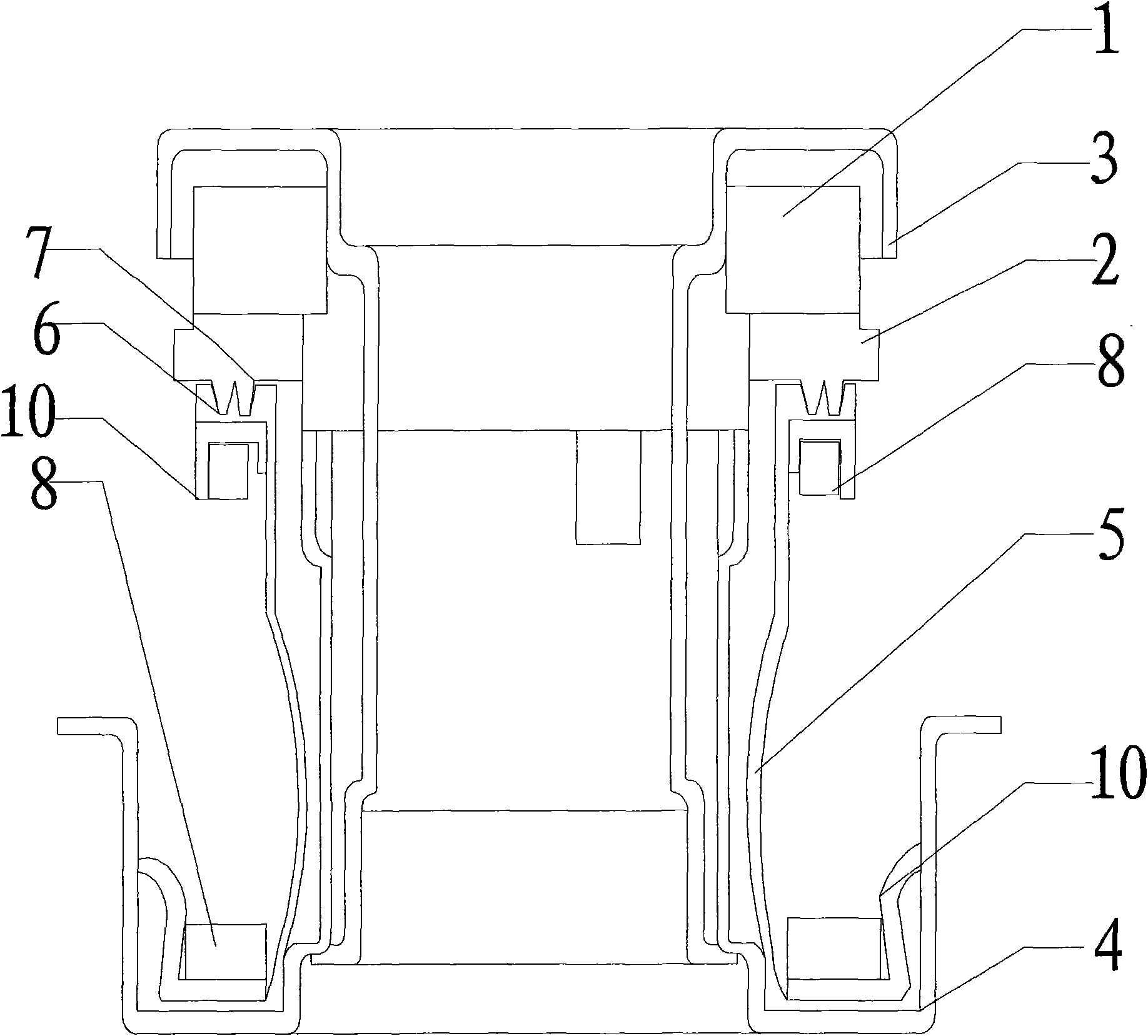

Embodiment 1

[0030] Such as figure 1 , 6As shown in and 7, a seal assembly includes a moving ring body 1, a static ring body 2, a moving ring shaft sleeve seat 3, a static ring shaft sleeve seat 4, a rubber sealing sleeve 5, and two sets of fixed skeletons 10, rubber The upper surface of the sealing sleeve 5 cooperates with the lower surface of the static ring body 2, the lower end of the rubber sealing sleeve 5 is set in the sleeve seat 4 of the static ring, the lower surface of the moving ring body 1 cooperates with the upper surface of the static ring body 2, and the rubber seal The upper surface of the sleeve 5 cooperates with the lower surface of the static ring body 2 in the manner of a tapered convex body 6 and a tapered groove 7 . The tapered convex body 6 is arranged on the lower surface of the stationary ring body 2, and the corresponding tapered groove 7 is arranged on the upper surface of the rubber sealing sleeve 5. The tapered convex body 6 and the corresponding tapered conc...

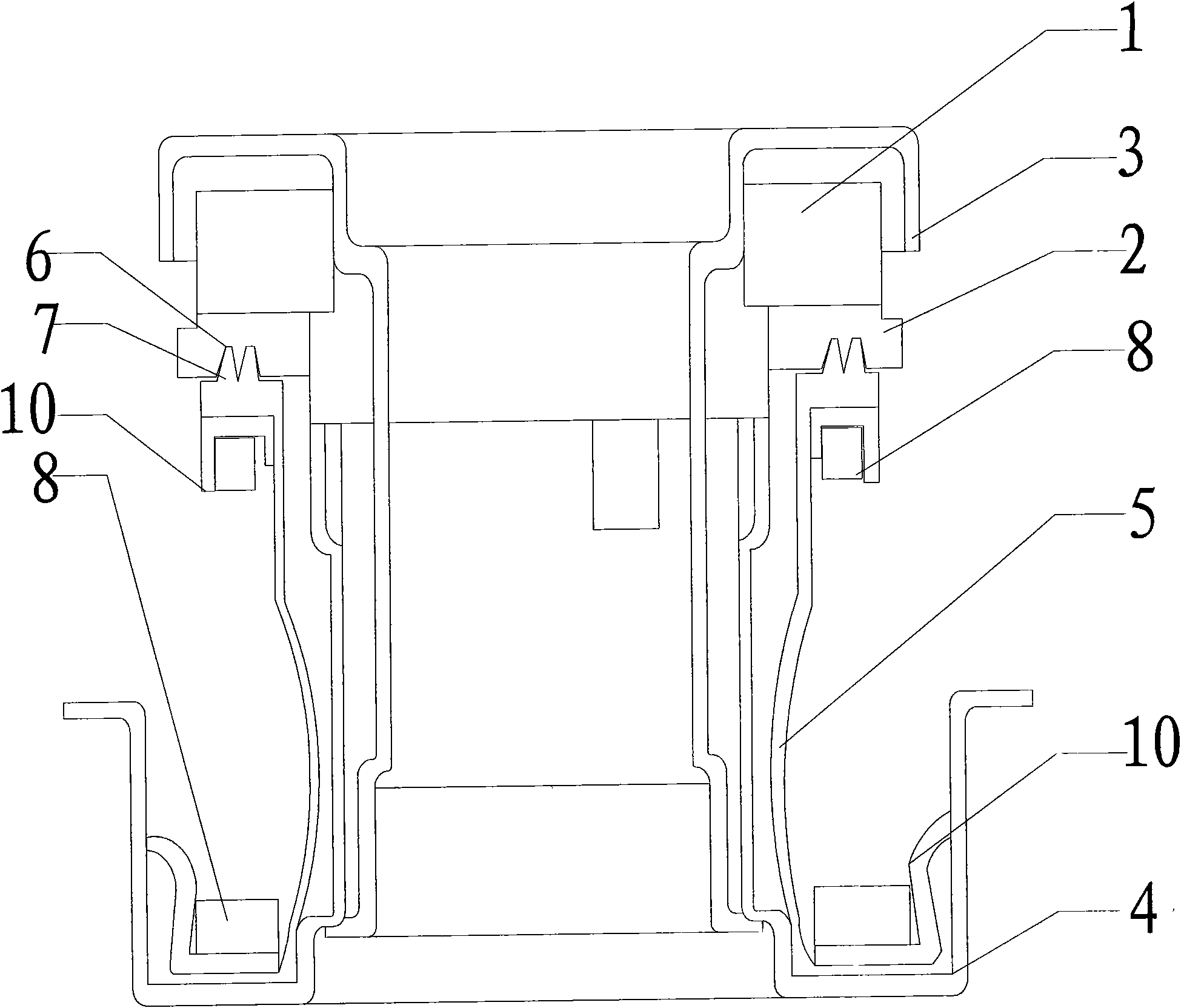

Embodiment 2

[0032] Such as figure 2 , 6 As shown in and 7, a seal assembly includes a moving ring body 1, a static ring body 2, a moving ring shaft sleeve seat 3, a static ring shaft sleeve seat 4, a rubber sealing sleeve 5, and two sets of fixed skeletons 10, rubber The upper surface of the sealing sleeve 5 cooperates with the lower surface of the static ring body 2, the lower end of the rubber sealing sleeve 5 is set in the sleeve seat 4 of the static ring, the lower surface of the moving ring body 1 cooperates with the upper surface of the static ring body 2, and the rubber seal The upper surface of the sleeve 5 cooperates with the lower surface of the static ring body 2 in the manner of a tapered convex body 6 and a tapered groove 7 . The tapered convex body 6 is arranged on the upper surface of the rubber sealing sleeve 5, and the corresponding tapered groove 7 is arranged on the lower surface of the static ring body 2. The tapered convex body 6 and the corresponding tapered The s...

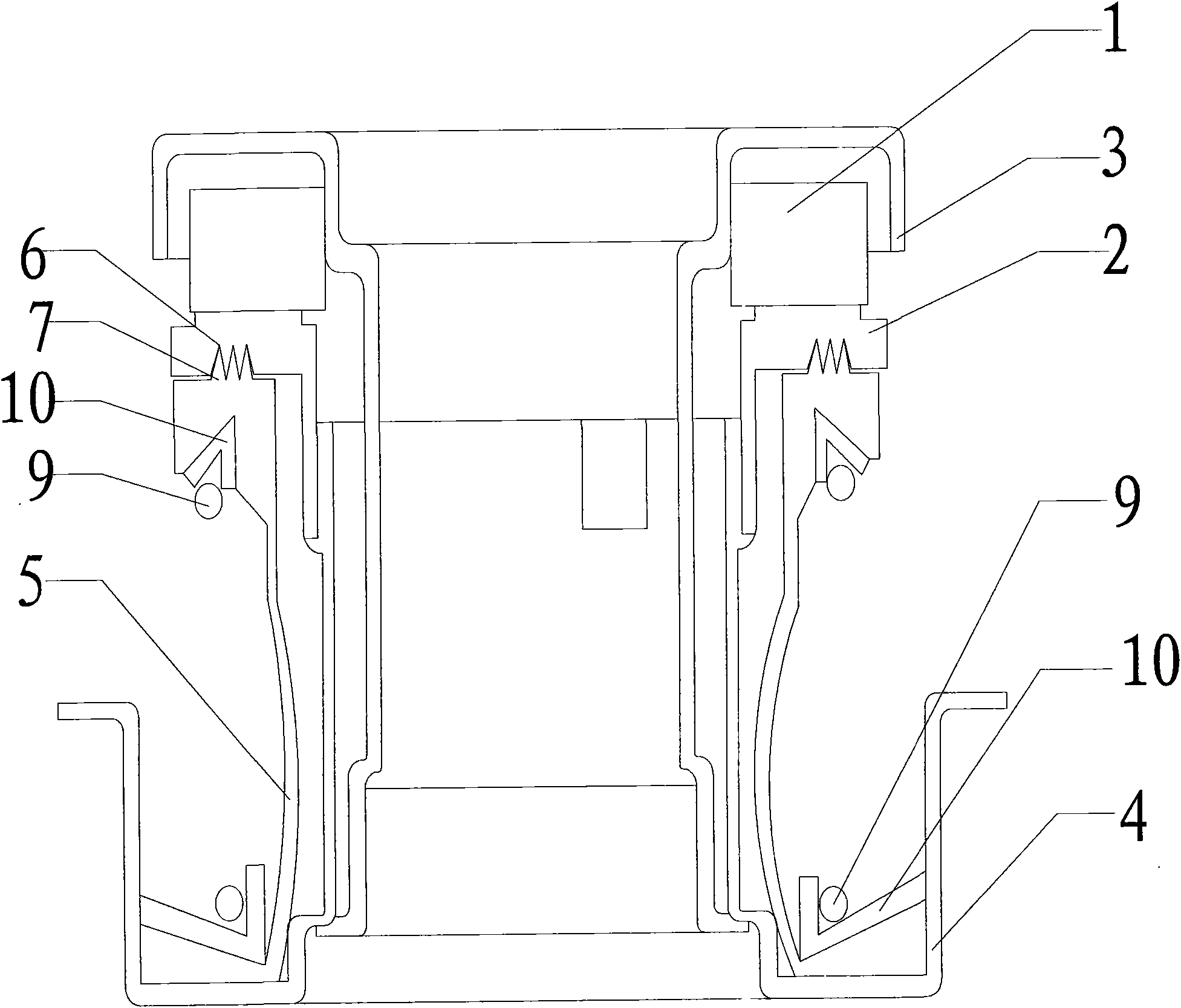

Embodiment 3

[0034] Such as image 3 , 6 As shown in and 7, a seal assembly includes a moving ring body 1, a static ring body 2, a moving ring shaft sleeve seat 3, a static ring shaft sleeve seat 4, a rubber sealing sleeve 5, and two sets of fixed skeletons 10, rubber The upper surface of the sealing sleeve 5 cooperates with the lower surface of the static ring body 2, the lower end of the rubber sealing sleeve 5 is set in the sleeve seat 4 of the static ring, the lower surface of the moving ring body 1 cooperates with the upper surface of the static ring body 2, and the rubber seal The upper surface of the sleeve 5 cooperates with the lower surface of the static ring body 2 in the form of a tapered convex body 6 and a tapered groove 7. The tapered convex body 6 is arranged on the upper surface of the rubber sealing sleeve 5, corresponding to the tapered The groove 7 is arranged on the lower surface of the static ring body 2, the shape of the tapered convex body 6 and the corresponding ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com