Electric fuse ignition device, electric detonator comprising electric fuse ignition device, electronic detonator comprising electric fuse ignition device, and manufacturing methods for electric detonator and electronic detonator

An ignition device and electronic detonator technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of high cost, poor welding accuracy, bridge wire breakage, etc., and achieve simple manufacturing process, precise detonation accuracy, and high resistance value accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

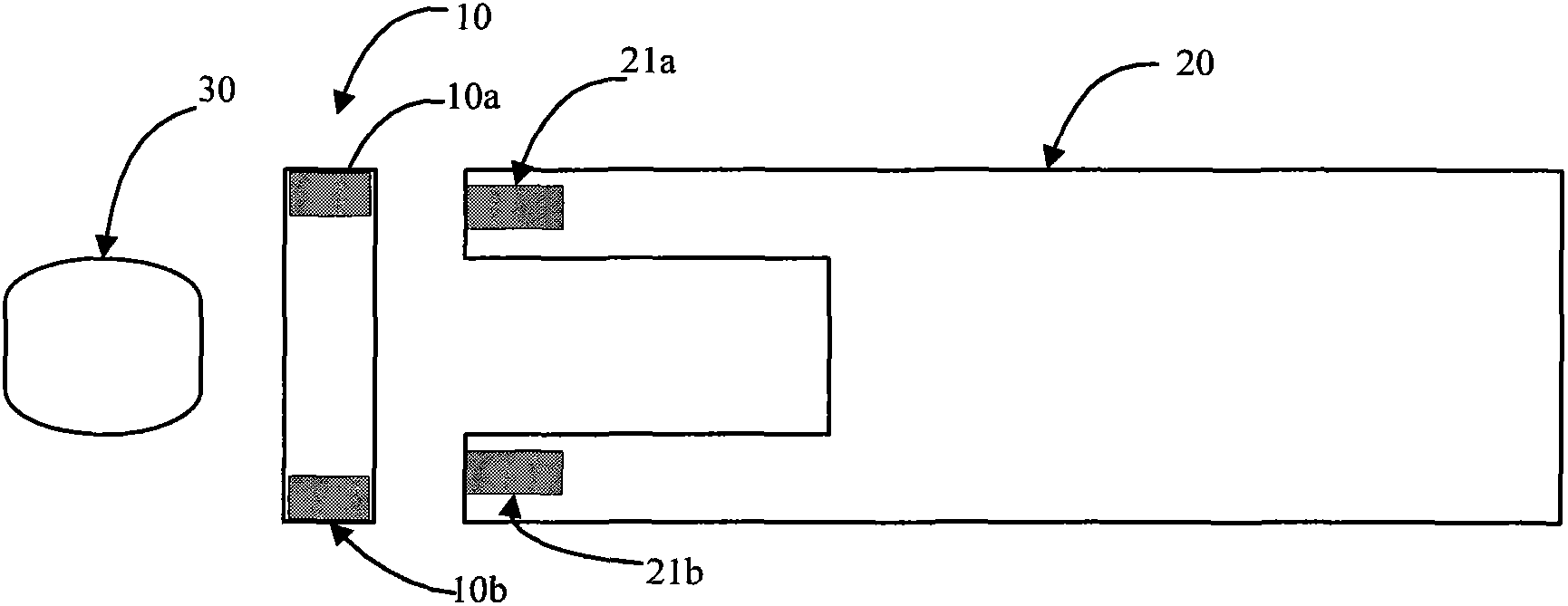

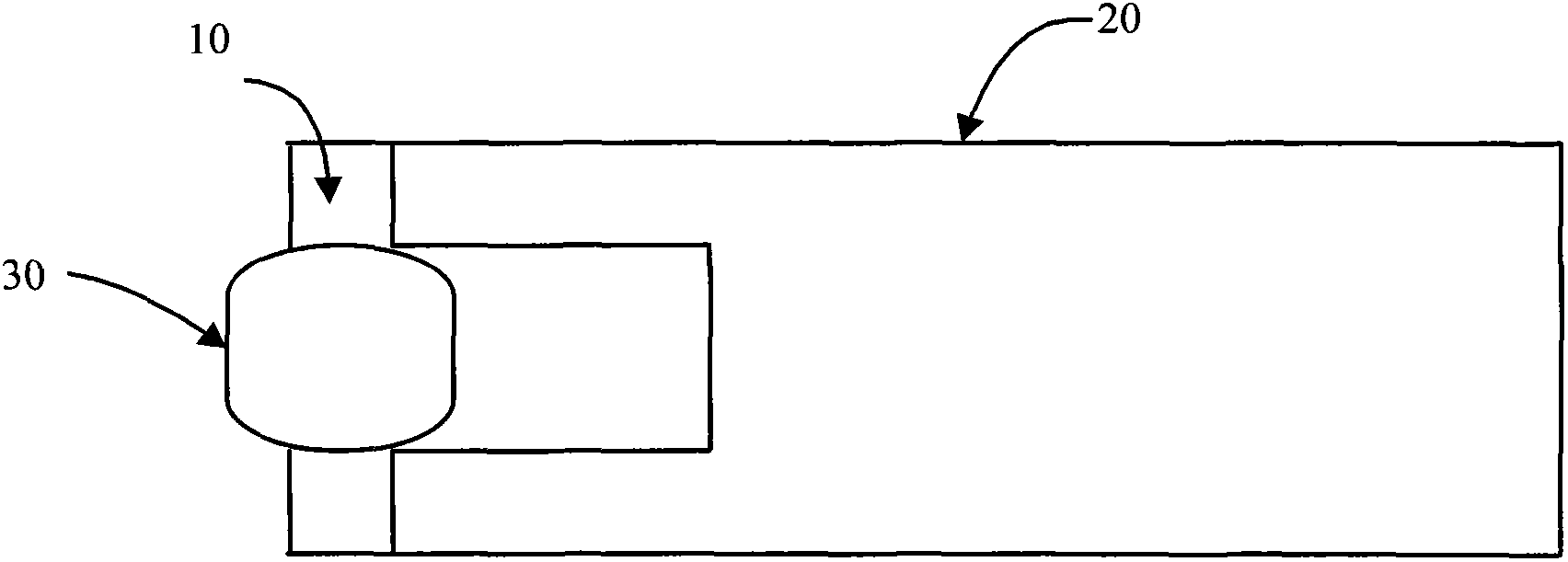

[0044] Figure 1-2 The following descriptions describe specific embodiments of the invention to teach those skilled in the art how to make and use the best mode of the invention. In order to teach inventive principles, some conventional aspects have been simplified or omitted. Those skilled in the art will appreciate that variations from these embodiments will fall within the scope of the invention. Those skilled in the art will appreciate that the features described below can be combined in various ways to form multiple variations of the invention. As a result, the invention is not limited to the specific embodiments described below, but only by the claims and their equivalents.

[0045] figure 1 The electrical fuze firing device according to the invention is shown disassembled. figure 2 An integrated electrical fuze firing device according to the invention is shown. Such as figure 1 with 2 As shown, the electric fuze ignition device according to the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com