Circular ball type electric booster steering device

An electric power steering and steering gear technology, applied in electric steering mechanisms, mechanical steering gears, etc., can solve problems such as difficulty in coordinating low-speed steering portability, inability to adjust and control, and poor steering wheel alignment ability, thereby shortening production. and development cycle, high degree of assembly automation, the effect of reducing steering force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

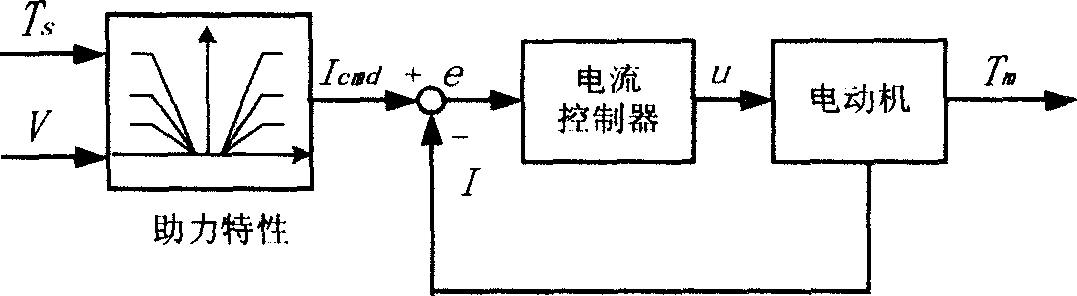

[0023] Such as figure 1 As shown, the electronic control unit according to the collected steering wheel torque T s Determine the target current Icmd of the booster motor with the vehicle speed V, and then perform feedback tracking control on the booster motor current according to the actual current I and target current Icmd of the booster motor.

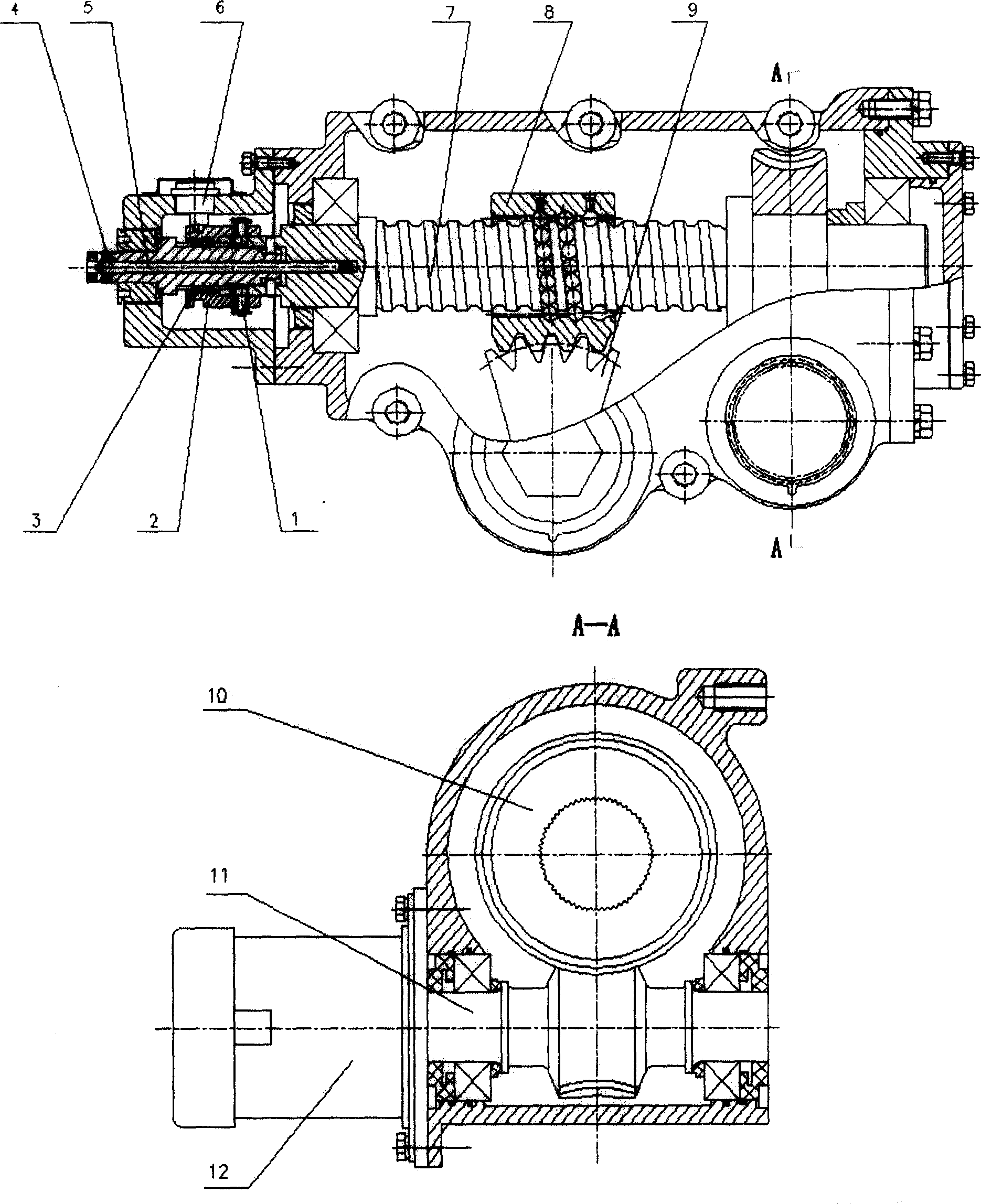

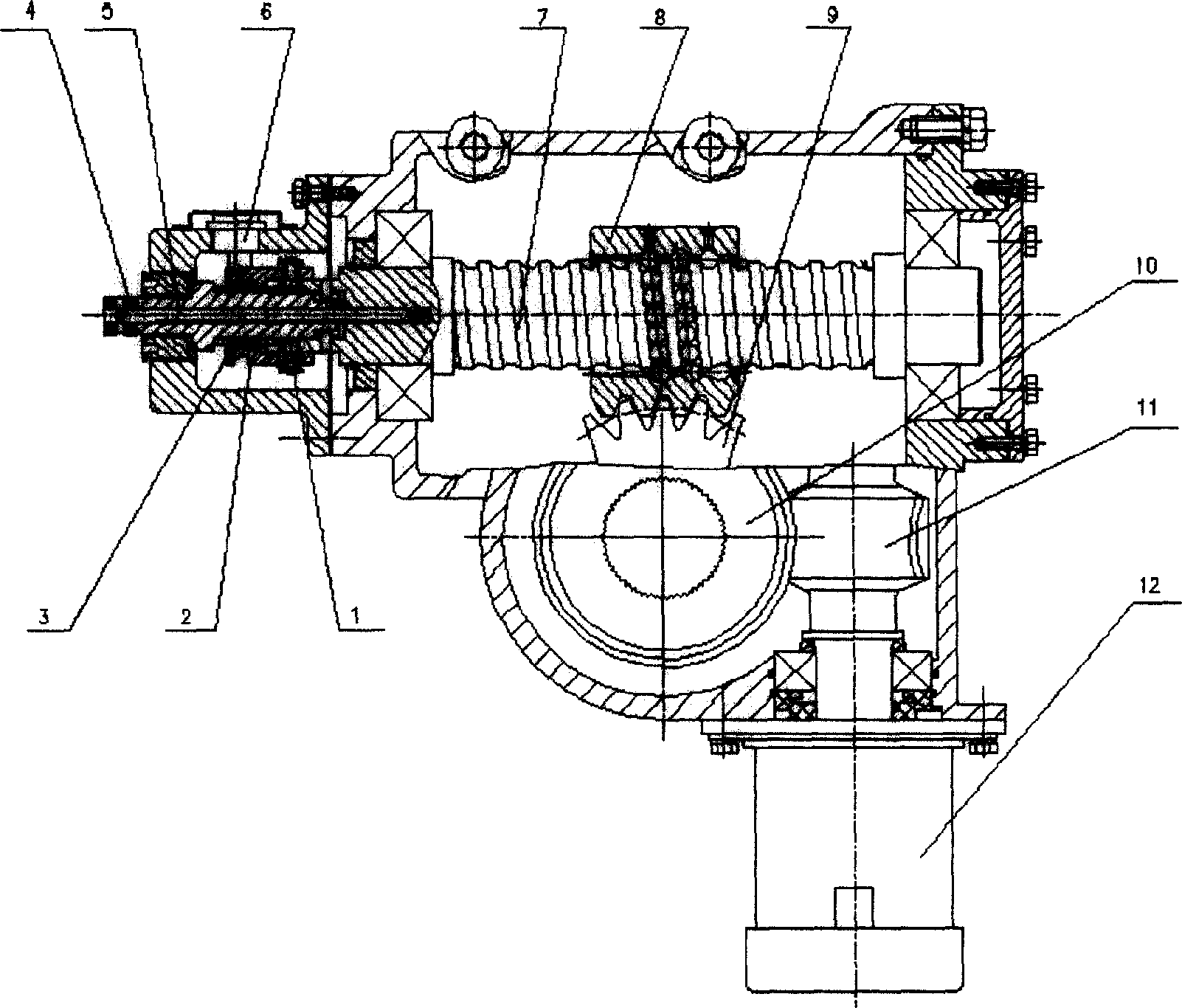

[0024] Such as figure 2 As shown, one end of the torsion bar 5 is connected with the input end 4 of the steering gear, and the other end is rigidly connected with the screw rod 7 through an interference fit. Connected, and by cooperating with the spiral groove on the sliding sleeve 2, the sliding sleeve 2 rotates while generating axial movement, the axial movement of the sliding sleeve 2 is measured by the angular displacement sensor 6, and the relative deformation of the torsion bar 5 ( That is, the relative rotation angle between the steering gear input end 4 and the screw rod 7) is converted into an electric signal representing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com