Single crystal and directional solidification material turbine rotor blade tip repairing method and tool

A directional solidification, turbine rotor technology, applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of difficult clamping and positioning of parts, interference in the equipment process, etc., and achieve fast and efficient forming and comprehensive repair. High efficiency and good surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] EOS M290 laser selective melting (SLM) equipment was used to repair the wear damage of the DD32 single crystal turbine blade tip of a certain type of engine. The specific steps are as follows:

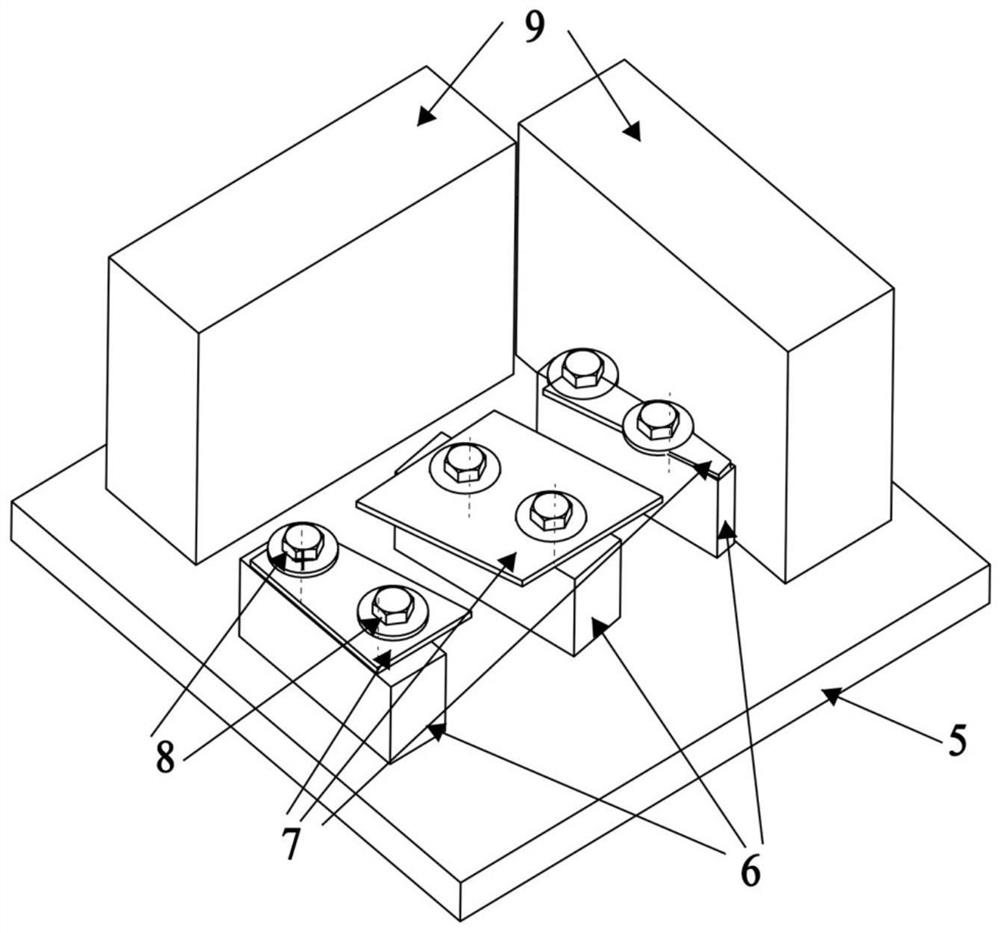

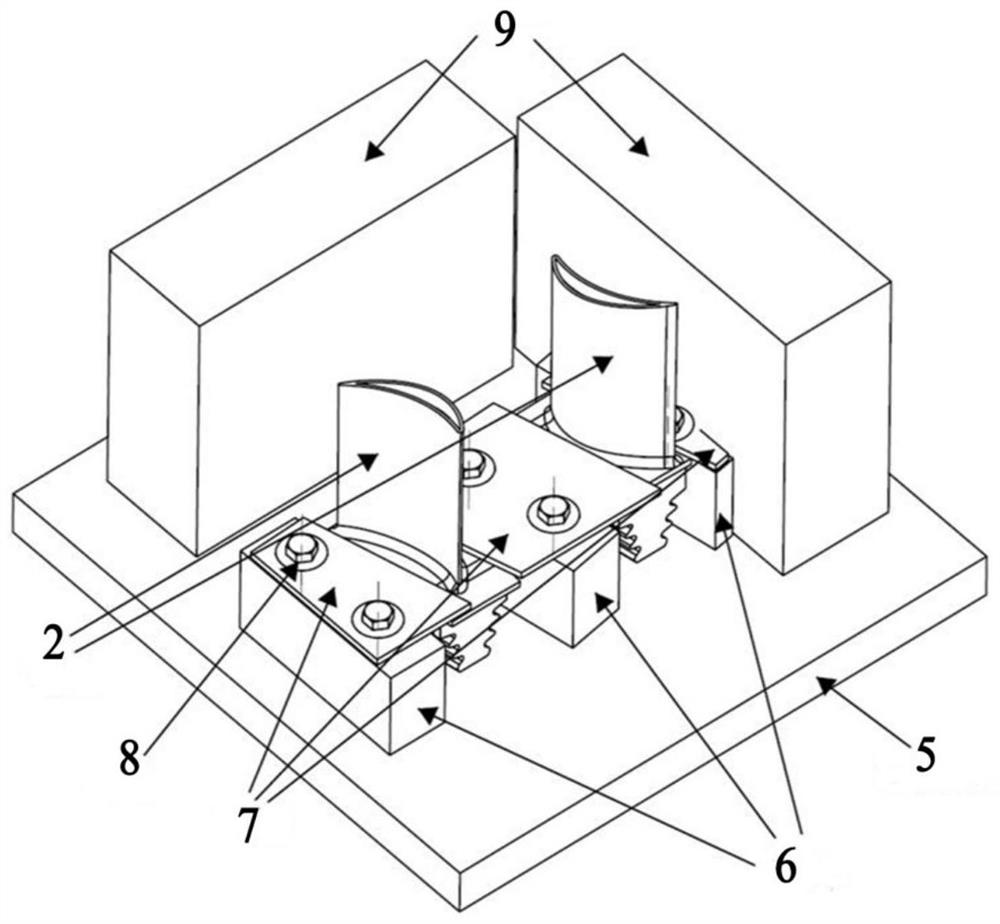

[0061] S1. Tooling design and blade clamping: Design a tooling to assist blade positioning, clamping and laser selective melting (SLM) repair:

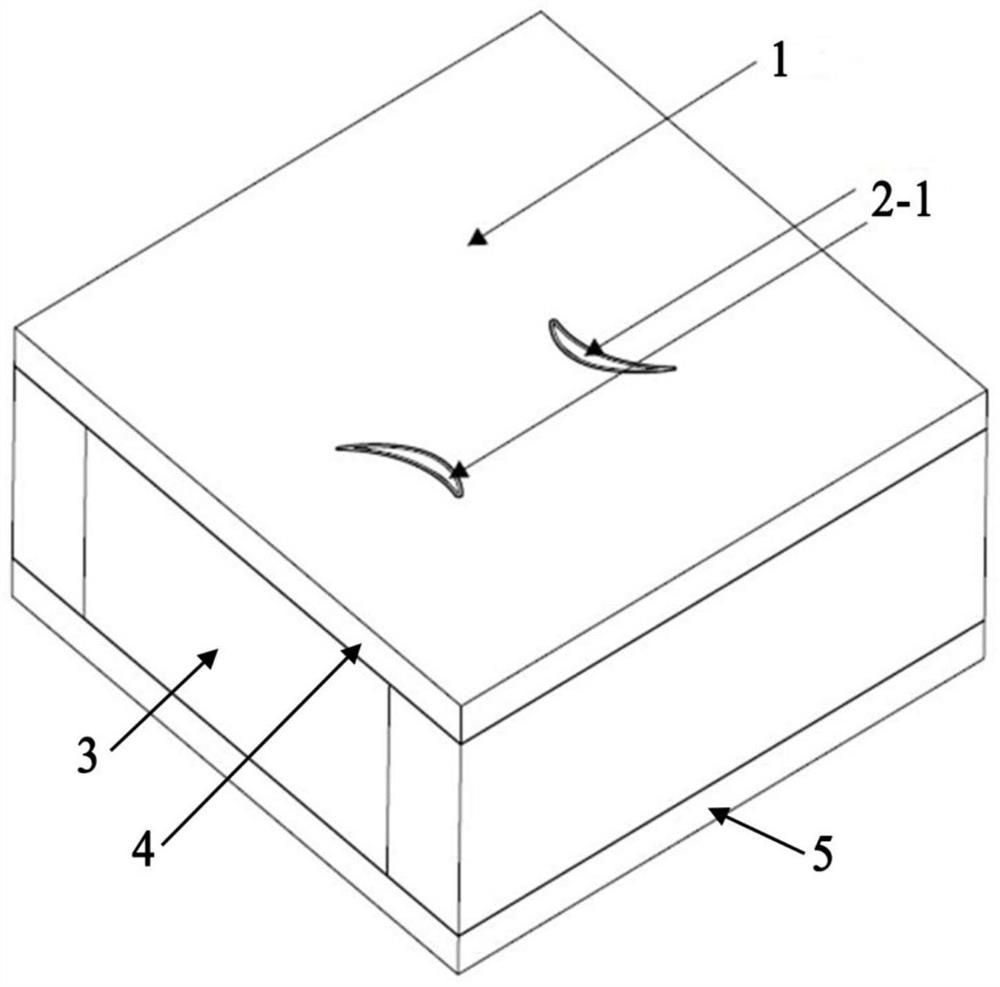

[0062] The side substrate 3 is a tooling side substrate with a size of 252mm×252mm×5mm, which is used to support and fix the upper substrate and substrate base. The shape is rectangular, and the size of the substrate depends on the size of the blade;

[0063] The upper substrate 4 has the same length, width and height as the substrate base, and a through hole with the same size and shape as the blade tip is provided at the blade installation position;

[0064] The size of the substrate base 5 is 252mm (length) × 10mm (width) × 125mm (height), and there are M8 threaded holes at the four corners of the substrate base, which can be connect...

example 2

[0082] Arcam A2X electron beam selective melting (EBM) equipment was used to repair the wear damage of the turbine blade tip of a certain type of engine DZ125 directionally solidified alloy. The specific steps are as follows:

[0083] S1. Tool design and blade clamping: Design a tool to assist blade positioning, clamping and electron beam melting (EBM) repair:

[0084] The side substrate 3 is a tooling side substrate with a size of 210mm×210mm×5mm, which is used to support and fix the upper substrate and substrate base. The shape is rectangular, and the size of the substrate depends on the size of the blade;

[0085] The upper substrate 4 has the same length, width and height as the substrate base, and a through hole with the same size and shape as the blade tip is provided at the blade installation position;

[0086] The size of the substrate base 5 is 210mm (length) × 10mm (width) × 125mm (height);

[0087] The size of the spacer 6 is 84mm (length) × 40mm (height), and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com