Reverse modeling method using mesh data as feature

A mesh data, reverse modeling technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve problems such as long time and technical know-how, difficulty in adjusting surface quality, and inability to ensure parameterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, preferred embodiments of the present invention will be described with reference to the drawings. In the following description and drawings, the same reference numerals are used to designate the same or similar components, thereby omitting repeated description of the same or similar components.

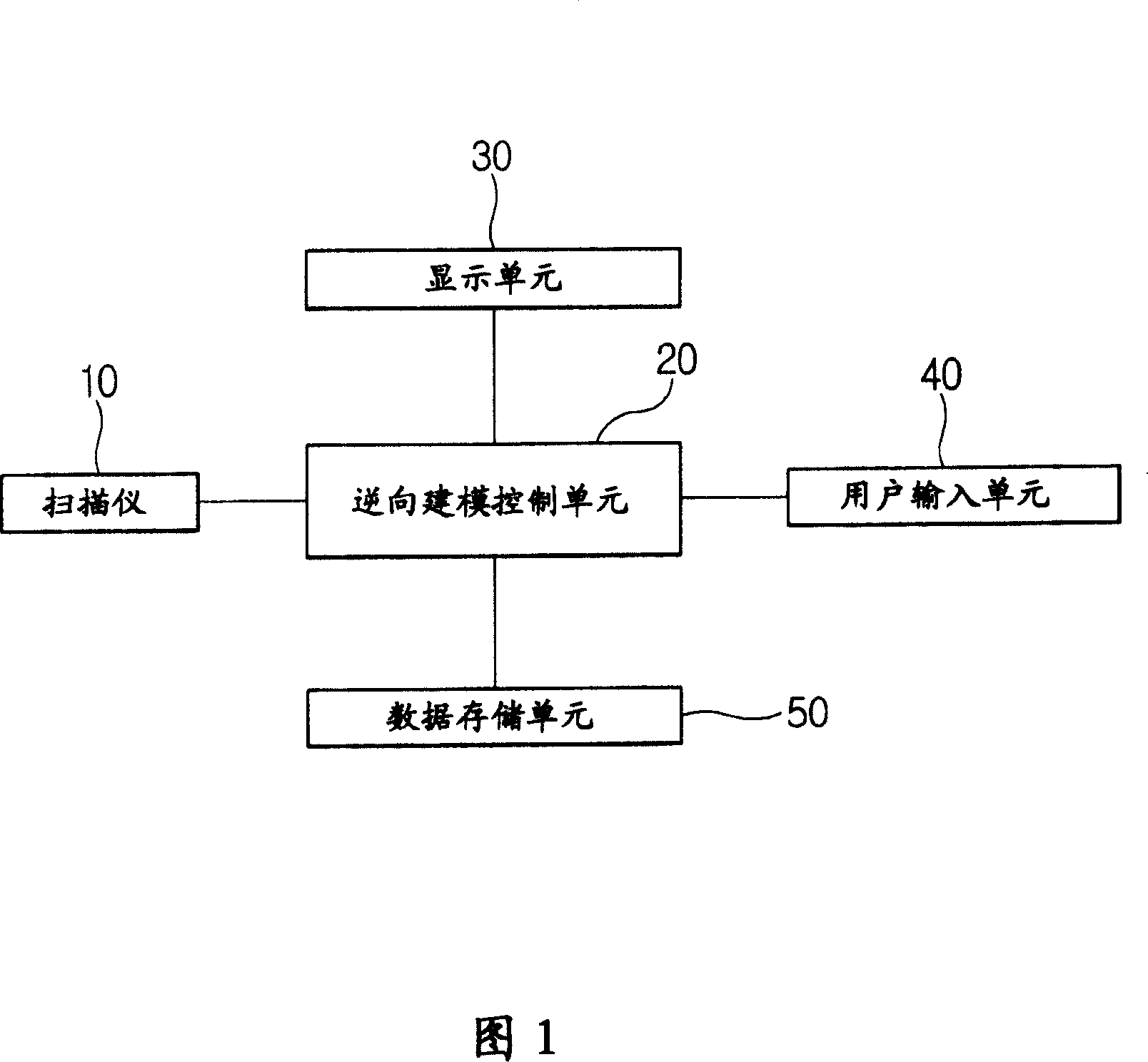

[0049] FIG. 1 is a block diagram showing the structure of an inverse modeling system using grid data as features according to the present invention. Referring to Fig. 1, the system for detecting reverse modeling target comprises: scanner 10, it is used to measure reverse modeling target; Reverse modeling control unit 20, it is used to control whole modeling system and carry out modeling function; Display A unit 30 for outputting scan data detected by the scanner 10, or outputting grid data (hereinafter referred to as "grid data") generated by transforming the scan data, thereby allowing the user to confirm the data; the user An input unit 40 for detecting setting data inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com