Fast reverse modeling method based on three-dimensional feature extraction

A technology of reverse modeling and three-dimensional features, applied in 3D modeling, image data processing, instruments, etc., can solve the problem of low material cost, achieve the effect of increasing processing time, reducing difficulty, and fast reverse modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

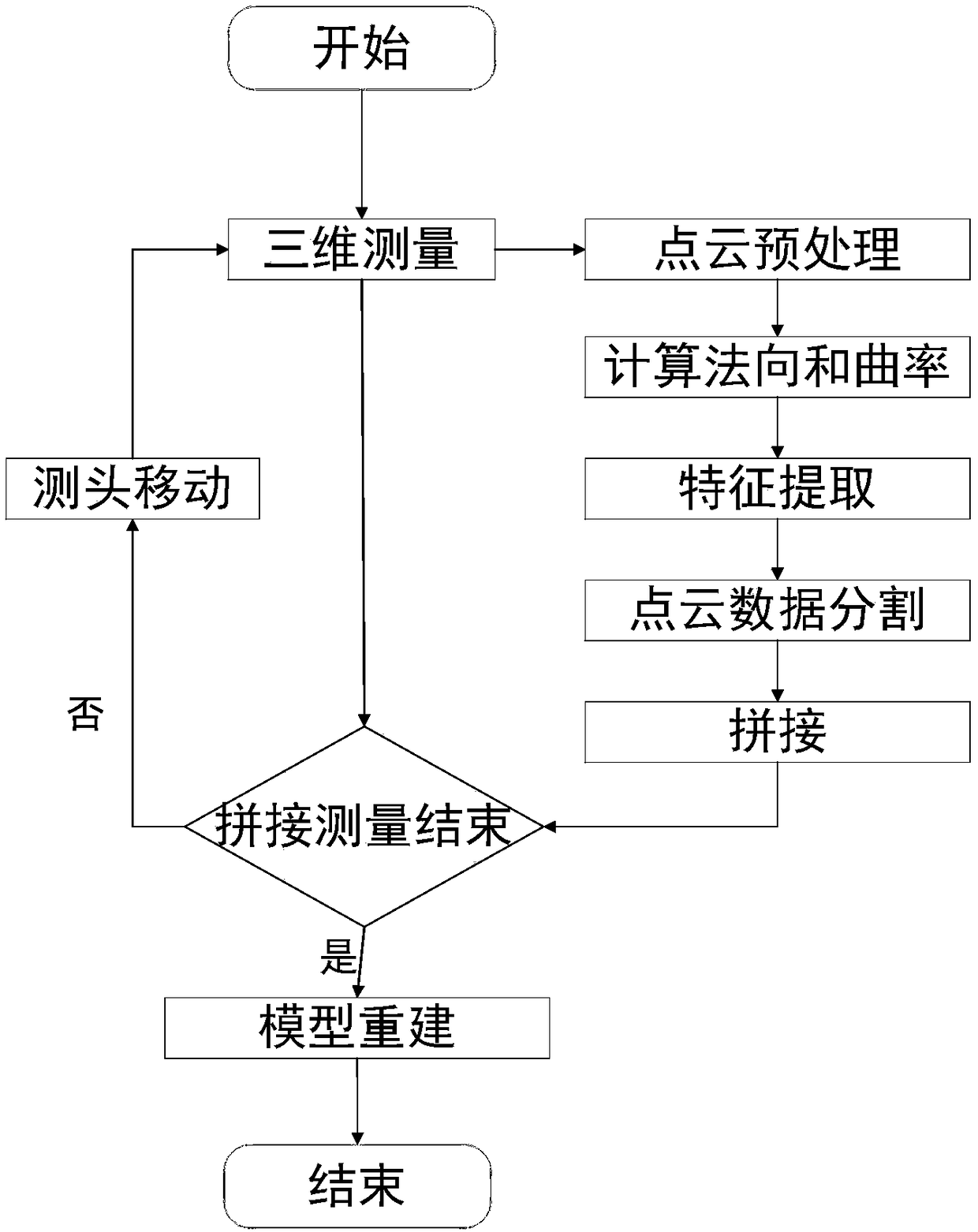

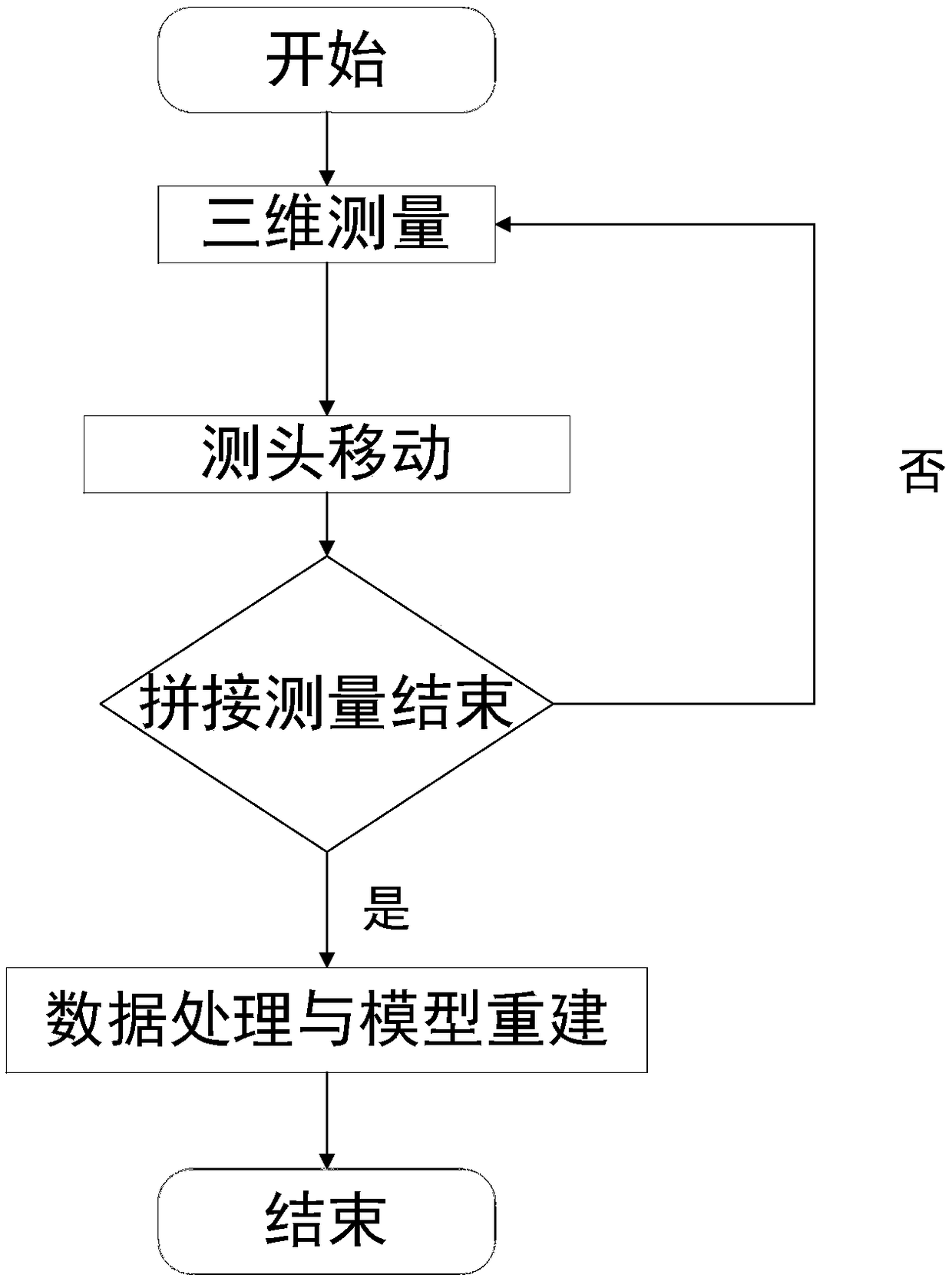

[0031] Refer to attached figure 1 , a fast reverse modeling method based on three-dimensional feature extraction, including the following steps:

[0032] 1. The probe moves to measure the splicing of large structural parts.

[0033] The measuring equipment can only obtain the 3D point cloud of the local area of the large structural part in one measurement, and obtain multiple single-field 3D point cloud data of the large structural part by moving the probe, and obtain the complete 3D point cloud data of the large structural part through splicing. This process is carried out simultaneously with the processing of 3D point cloud data, which shortens the reverse modeling time.

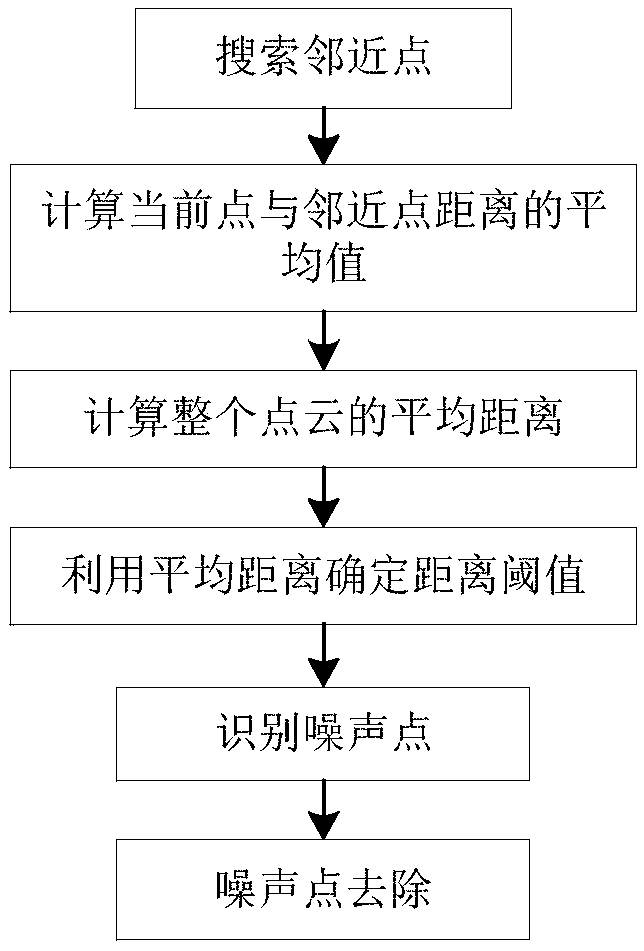

[0034] 2. Delete the noise points of the point cloud, and then use the method of quadratic surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com